Spray better with BETE

Spray Nozzles, Fabrications, & Spraying Systems

Engineered for precision.

Proven reliability and performance.

Proud to manufacture in the USA.

Maximize efficiency and conserve resources with BETE spray technology.

Let us solve your spraying challenge.

Let us solve your spraying challenge.

CONTACT AN EXPERT

Spray Nozzles, Spray Lances, & Spray Systems

All Spray Nozzles

Discover BETE spray nozzles

Full Cone Spray Nozzles

Explore our full cone spray nozzles

Air Atomizing Nozzles

High-performance air atomizing nozzles

Tank Cleaning Nozzles

Find your tank cleaning solution

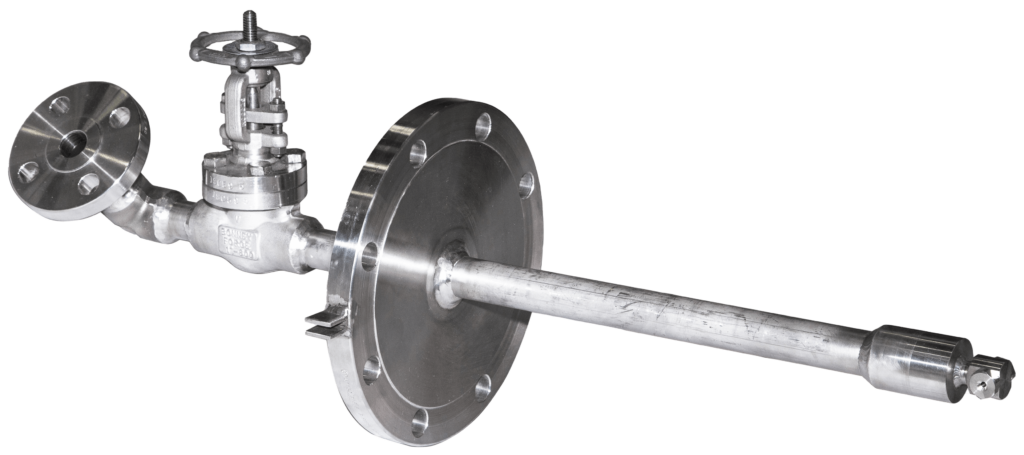

Spray Lances, Injectors, & Quills

Tailored to your specific process

Automated Spray Systems

Optimize your spray process

Learn How Our Customers Save Time & Money With BETE Spray Solutions

From High Temps to High Quality: A Tire Manufacturer’s Success Story

High temperatures in many industrial manufacturing processes can lead to poor product quality and reduced output due to process slowdowns. Whether you’re producing high-performance rubber tires or weather-resistant shingles, BETE offers effective, efficient cooling systems that preserve material integrity, lower operating costs, and keep production moving.

Read More

BETE’s FlexiSan Modular Spray System Cuts Conveyor Cleaning Time & Saves Bakery Over a Half a Million Dollars a Year

Cleaning and sanitizing conveyors is critical in food processing to ensure product quality and safety. Traditional manual cleaning methods are often time-consuming, costly, and can jeopardize worker safety. By automating processes and implementing a spraying system, processors can streamline Open Plant Cleaning (OPC), reduce labor, improve worker safety, and minimize downtime — ultimately increasing their bottom line.

Read More

Automated Spray System for Chemical Processing Enhances Gas Cooling Performance and Reliability

A demineralized water injection system is needed to quench calciner furnace exhaust gas upstream of dust

collection equipment at a chemical processing plant during the manufacture of specialty catalyst. Spray

nozzles need to produce small droplet sizes to achieve complete evaporation, which requires pumps for

high-pressure water supply, controls, and instrumentation to regulate and monitor the gas temperature.

Read More

Featured Products

Blog Posts

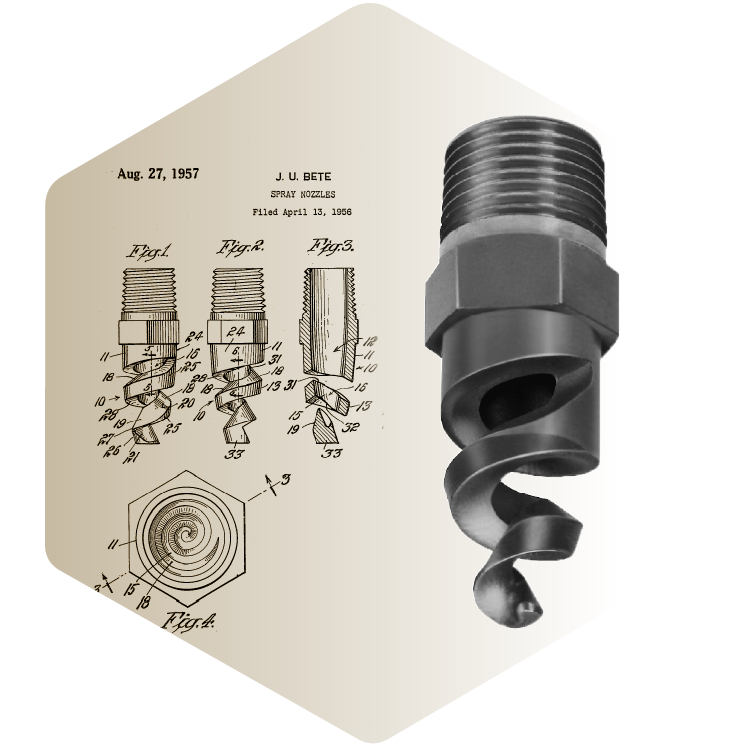

The History & Evolution of the BETE Spiral Nozzle

Overview The BETE Spiral Nozzle — often recognized by its distinctive corkscrew shape — represents a cornerstone of spray nozzle engineering. Invented by John Bete in 1948, the spiral became the foundation of BETE, being...

What is Droplet Entrainment, and How Can You Mitigate It?

Droplet entrainment is a common yet critical issue in many industrial processes, especially those involving fluid dynamics, such as distillation, gas cooling systems, and cooling towers. Understanding droplet entrainment, how it occurs, and the strategies...

BETE’s MaxiPass® (MP) Full Cone Nozzle: High Performance, Maximum Free Passage, and Low Entrainment

When selecting the best spray nozzle to handle your process-critical applications, there is no need to compromise efficiency and longevity. BETE’s MP full cone nozzle has been the worldwide standard of excellence for over 45...

Discover the BETE Difference

Our spray technology innovations improve sustainable operations in a broad range of industries – including Food & Beverage Processing, Chemical Processing, Energy, and Pollution Control. We listen to and partner with our customers to ensure the optimal solution for their spraying challenge.

LEARN MORE ABOUT BETE