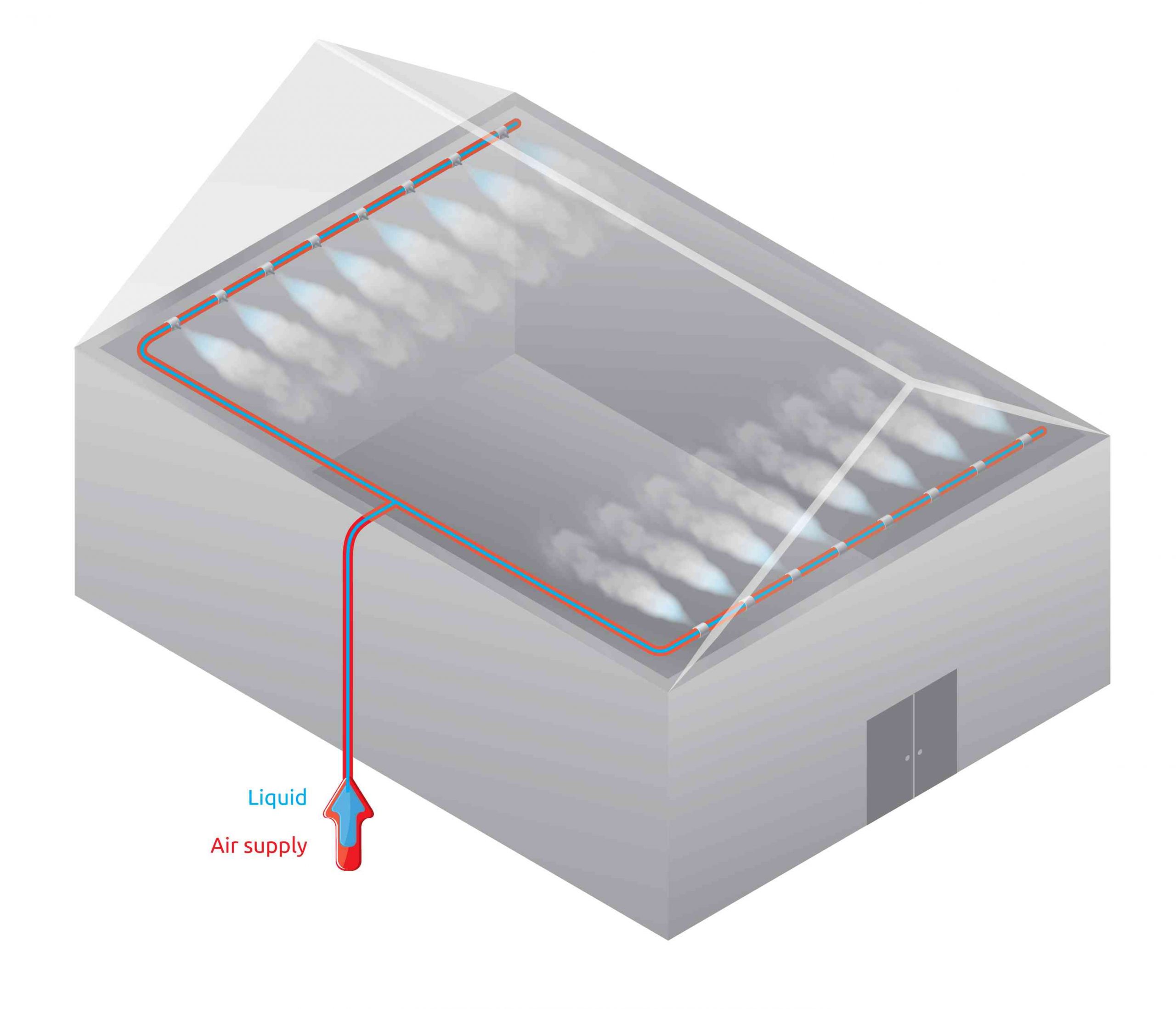

In many industrial processes, commercial processes, and agricultural settings, it is necessary or advantageous to increase the air’s humidity (or water content) in a duct, chamber, or room. The fine atomization of water produced by misting or fog pattern spray nozzles effectively increases the humidity level.

The small water droplets produced by these nozzles can evaporate quickly, even at normal ambient temperatures, thus increasing the amount of water present in the air. Under most general atmospheric environmental conditions, only a relatively small amount of water is required to evaporate and increase relative humidity effectively. BETE offers a wide variety of nozzles with low flow rates and fine atomization used for humidification applications.

Common Uses & Industries

Important factors to consider:

Initial and desired relative humidity levels

Size and shape of the area to be humidified

Ventilation rates & air currents in rooms or air flow rate & velocities in ducts

Temperature and environment

Water quality/filtration

Type of nozzle and spray pattern being used

- Available nozzle mounting locations and nozzle spacing

- Availability of compressed air

Nozzle material

- Stainless steel is a standard selection to resist corrosion in humid environments

Available/required flow rate

Available pressure drop (∆P) across the nozzle

- ∆P = supply pressure at nozzle inlet – process pressure outside nozzle