The petroleum and chemical industries use vacuum distillation to help separate individual components and compounds from bulk process streams.

This process is essential in separating hydrocarbon fractions without high temperatures that could damage the fractions and cause coking. Vacuum is employed to lower the sprayed liquid’s boiling point, reducing the temperatures at which the more volatile elements will flash and reducing the energy/heat input required.

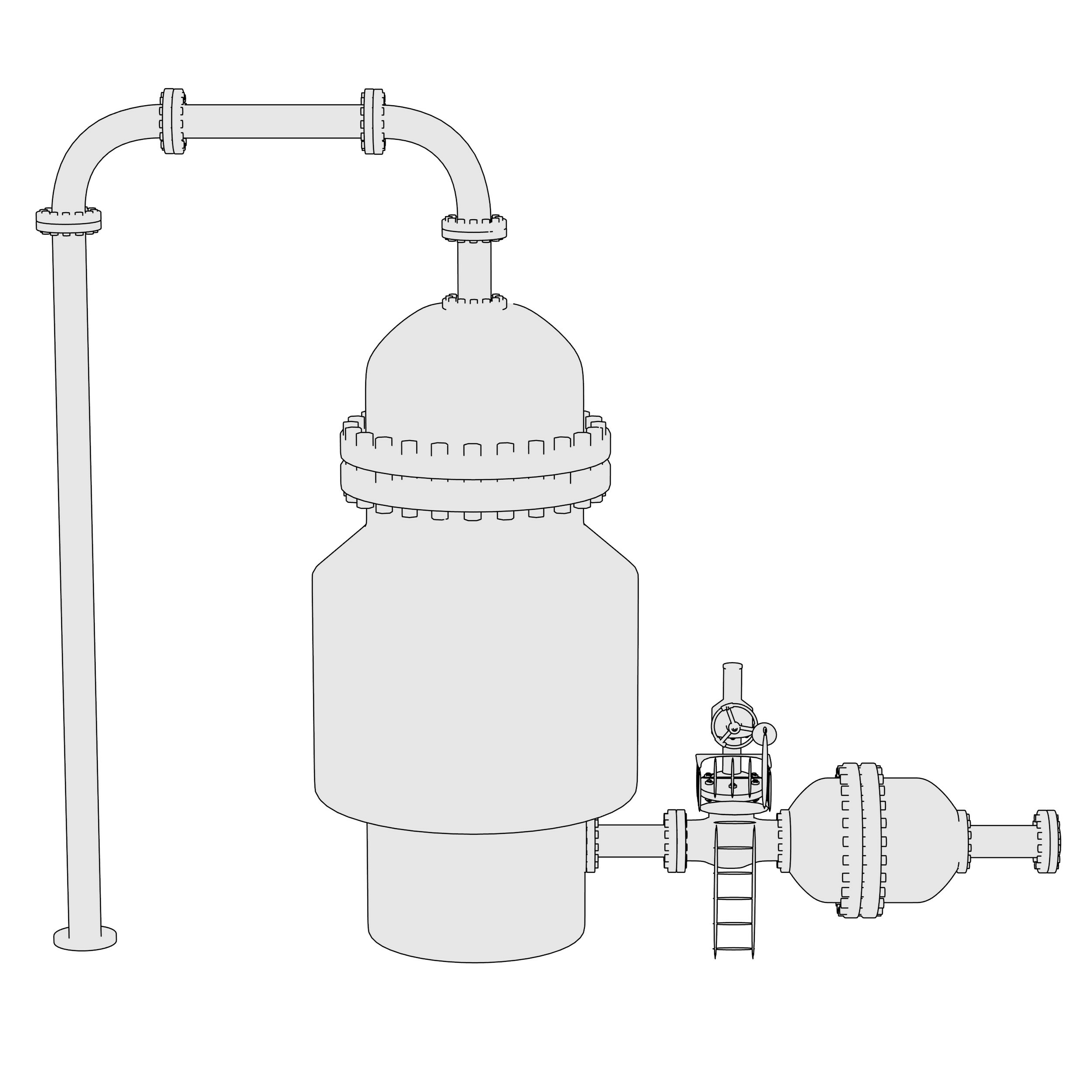

Spray nozzles frequently distribute the process fluids into the vacuum distillation units. Well-atomized sprays produced by nozzles increase the exposed surface area of the process fluid, thereby increasing the evaporation rate and separation efficiency. When packed columns are utilized in vacuum towers, where the gas side pressure drop must be low, spray nozzles also uniformly wet the packing, over which the gas flows and contacts the liquid.

Common Uses And Industries

Important factors to consider:

Flow rate, spacing, uniformity, clog-resistance

Process vessel pressure, temperature, and fluid composition

Required material of construction for abrasive or corrosive environments

Required coverage

Potential for spray media flashing before nozzle orifice

Available/required flow rates

Available pressure drop (∆P) across the nozzle

- ∆P = supply pressure at nozzle inlet – process pressure outside nozzle

- Important to note where the process side is under vacuum