Overview

Pollution Control Equipment Protection

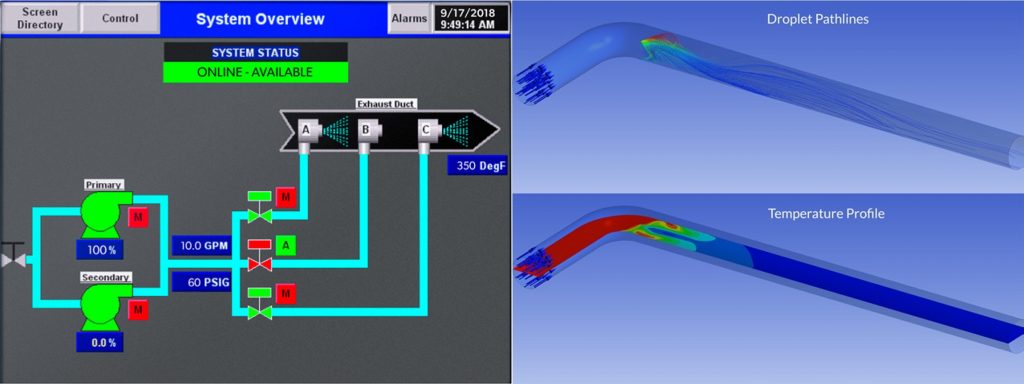

To protect downstream pollution control equipment, a customer asked BETE to provide a water injection system to cool hot exhaust gases from 1200° F down to 350° F, with an added requirement that the injected water needed to evaporate entirely before reaching the end of the duct.

BETE Gas Cooling System

Our Advanced Spray Engineering department conducted a CFD study to determine the exact water flow rate and drop size requirements at various gas conditions. Using the results of this study, BETE engineers worked with the customer to design a pump skid and control system that met their exact needs.

The result is a stand-alone automated pump skid made to ASME B31.3 standards with a programmable logic controller, or PLC, that monitors downstream gas temperature and adjusts water flow rate to maintain a target outlet condition.

Due to the expectation for a wide range of flow rates, BETE selected a series of three spray injection lances, each outfitted with individual electric valves that open independently to supply the required spray volume.

Advantages of BETE Custom Spraying Systems

- Operate as a stand-alone unit or integrate with central plant control systems

- All aspects of the system designed to target spray parameters improve performance, reliability, and profitability

- Close coordination through all phases of the process to meet every mechanical, performance, and inspection requirement

- Extensive engineering and manufacturing resources under one roof

- Integrated 3D CAD/CAM design

- CFD, FEA, and Vibration Analysis

- Rapid prototyping

- CNC machining

- Investment casting

- ASME Section IX Qualified Welders

- ASQ Certified Quality Inspectors

- State-of-the-art spray laboratory

- Knowledgeable & personalized customer service

RESULTS

Calciner exhaust gas passes through a 90’ duct with a 28” diameter into a baghouse to capture particulate. Inserted into the duct are three spray lance assemblies. A transmitter monitors the temperature at the end of the exhaust duct as it enters the baghouse and provides a feedback signal to the control panel located on the pump skid. The control system adjusts the water flow rate to the lances based on the temperature sensor’s feedback to maintain a duct outlet temperature of 350° F. When the operating temperature is at or below the limit of 350° F, the lance valves close, and the pumps stop running – saving valuable resources.

BETE’s automated solution prioritizes the upstream flow control equipment to ensure nozzles are supplied with the proper fluid conditions to increase performance, reliability, efficiency, and profitability. The system’s responsive operations ensure complete evaporation while achieving the target temperature – even as the process conditions change.