BETE provides a range of high-quality spray nozzles that are useful for reducing the temperature of various components and parts. Many production processes require the product to be hot during work and then cooled back to ambient temperature. In metal processing industries, castings, extrusions, and hot-worked products fall into this category, as do any components that have been treated with heat. Many products are packaged hot in the food industry and must be cooled before storage and shipment.

Cooling a solid object is typically accomplished by spraying it with a coolant, most often water. The rate to cool an object with a water spray depends on the object’s shape, initial temperature, final desired temperature, the heat capacity of the object, and the convection coefficient between the object and the water. The shape considers the surface area, volume, and indirectly the thermal conductivity of the object. It is also essential to consider that the object’s ability to transfer heat may not be uniform, as it may be made of several substances.

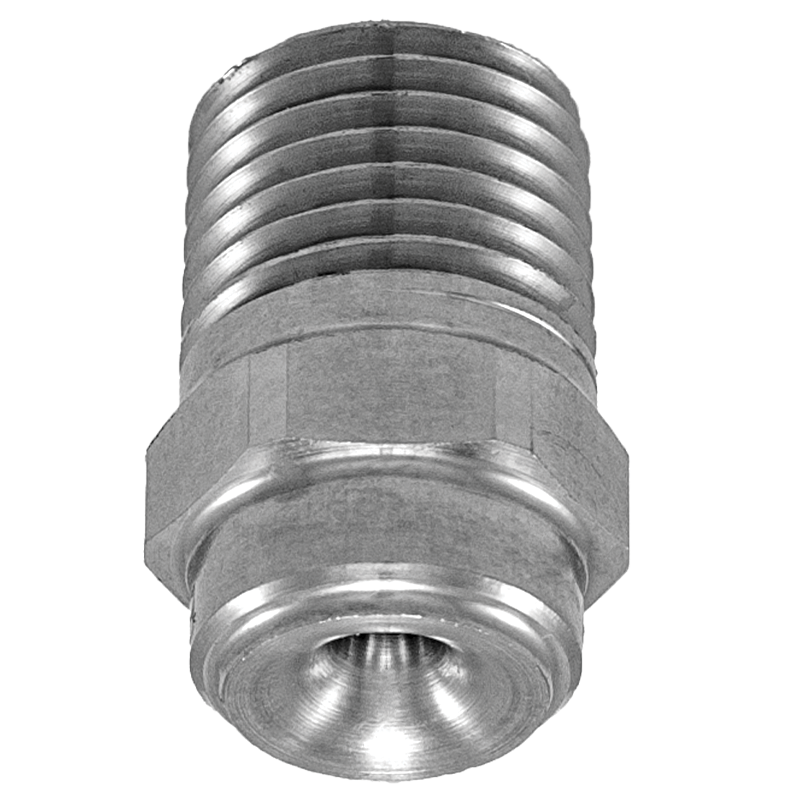

The principal idea is to distribute a high volume of water completely over the object, allowing the greatest contact and heat transfer from the object to the water. Nozzle spray is advantageous because it can cover virtually any object shape. Cooling takes time; the major advantage of spraying the coolant is the ability to speed up the process compared to simple submersion. As the object cools down, the water in contact with the object heats up. You should flush warm water to allow cooler water to contact the object to continue cooling. This flushing action is an inherent characteristic of the flood of liquid and spray dynamics produced by a spray nozzle.

In some specialty cooling applications, liquid nitrogen is sprayed to cool or freeze products in a time and cost-efficient manner. The extremely low boiling point of liquid nitrogen (-320 °F) allows it to maintain extremely low temperatures and high cooling efficiency in product cooling applications.

Common Uses And Industries

Important factors to consider:

Target temperature for cooling object(s)

Shape of object(s)

Specific heat of object(s) material

Speed of travel (if moving)

Required coverage

Available and required cooling media flow rate

Available liquid pressure drop (∆P) across the nozzle

- ∆P = supply pressure at nozzle inlet – process pressure outside nozzle