TANK CLEANING NOZZLES

CLEAN QUICKLY & EFFICIENTLY WITH BETE SPRAY TECHNOLOGY

BETE tank cleaning nozzles maximize the efficiency of cleaning tanks and equipment by ensuring proper distribution of the cleaning media and maximizing impact from the available flow rate and pressure of the system. They save significant time and money over other cleaning options such as "fill and drain" or manual entry (especially in hazardous environments).

We offer a complete line of tank cleaning nozzles designed for effective rinsing or removing difficult soils. Our tank cleaning nozzles use the latest spray technology to optimize industrial or hygienic tank and equipment cleaning applications. Rotational tank cleaning devices clean faster than traditional spray balls while reducing water and solvent consumption, saving time and money.

Find Your Tank Cleaning Nozzle by Tank Size

HydroWhirl® Orbitor

Rotary Jet High-Impact Tank Cleaning Devices for Large Tanks

Soil Type: Heavy

Cleaning Range: Up to 130 ft

Flow Rates: 22.6 to 160 GPM

Pressure: 45 to 145 GPM

Min. Entry Diameter: 5.0"

Max Temperature: 200°F

HydroWhirl® Orbitor 100

Rotary Jet High-Impact Tank Cleaning Devices

Soil Type: Heavy

Cleaning Range: Up to 56 ft

Flow Rates: 12 to 52.4 GPM

Pressure: 45 to 145 GPM

Min. Entry Diameter: 3.35"

Max Temperature: 200°F

HydroWhirl® Orbitor 100 XC

Extreme Clean (XC)-High Impact With Slowest Rotation For Heavy Residue

Soil Type: Heavy

Cleaning Range: Up to 56 ft

Flow Rates: 12.8 to 52.4 GPM

Pressure: 45 to 145 GPM

Min. Entry Diameter: 3.35"

Max Temperature: 200°F

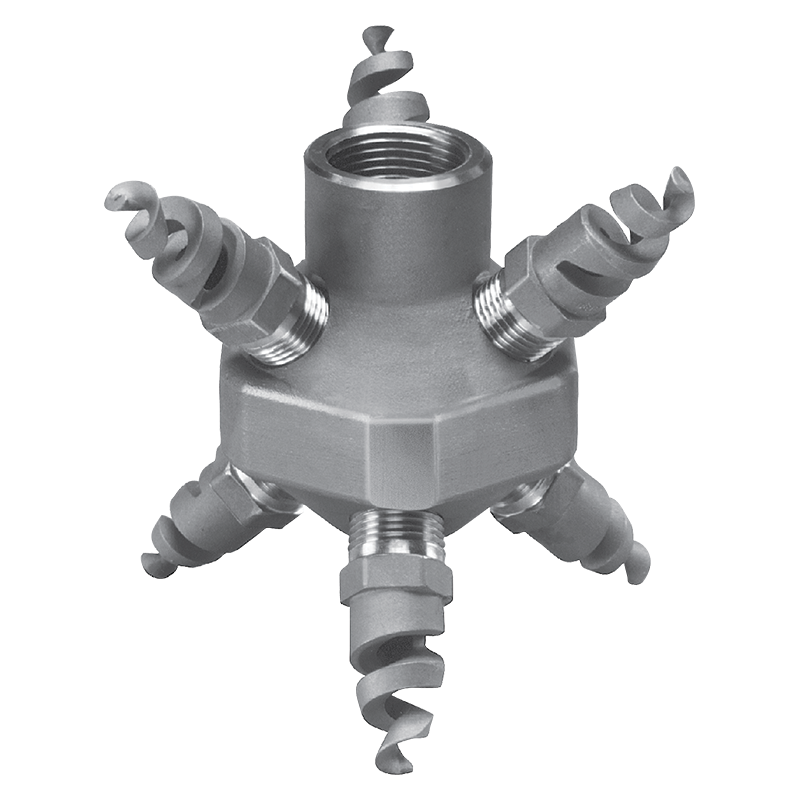

HydroClaw®

Reduce Down-Time With Patented Stationary Tank Cleaning Devices

Soil Type: Light to Moderate

Cleaning Range: Up to 10 ft

Flow Rates: 33 to 112 GPM

Pressure: 25 to 40 psi

Min. Entry Diameter: 2.4 to 2.9"

Max Temperature: 550°F

HydroWhirl® Stinger

Efficient Reactionary Force Tank Cleaning Devices

Soil Type: Light to Moderate

Cleaning Range: Up to 12 ft

Flow Rates: 1.09 to 117 GPM

Pressure: 10 to 60 psi

Min. Entry Diameter: .63 to 1.9"

Max Temperature: 200°F

HydroWhirl® Poseidon

PTFE Corrosion-Resistant Slow Rotating Tank Cleaning Devices

Soil Type: Moderate to Heavy

Cleaning Range: Up to 25 ft

Flow Rates: 4.45 to 82.4 GPM

Pressure: 10 to 60 psi

Min. Entry Diameter: 1.7 to 3.3"

Max Temperature: 200°F

HydroWhirl® Mini SS

Reactionary Force Tank Cleaning Devices for Small Tanks

Soil Type: Light to Moderate

Cleaning Range: Up to 6 ft

Flow Rates: 3.6 to 9.1 GPM

Pressure: 10 to 60 psi

Min. Entry Diameter: .84 to 1.0"

Max Temperature: 266°F

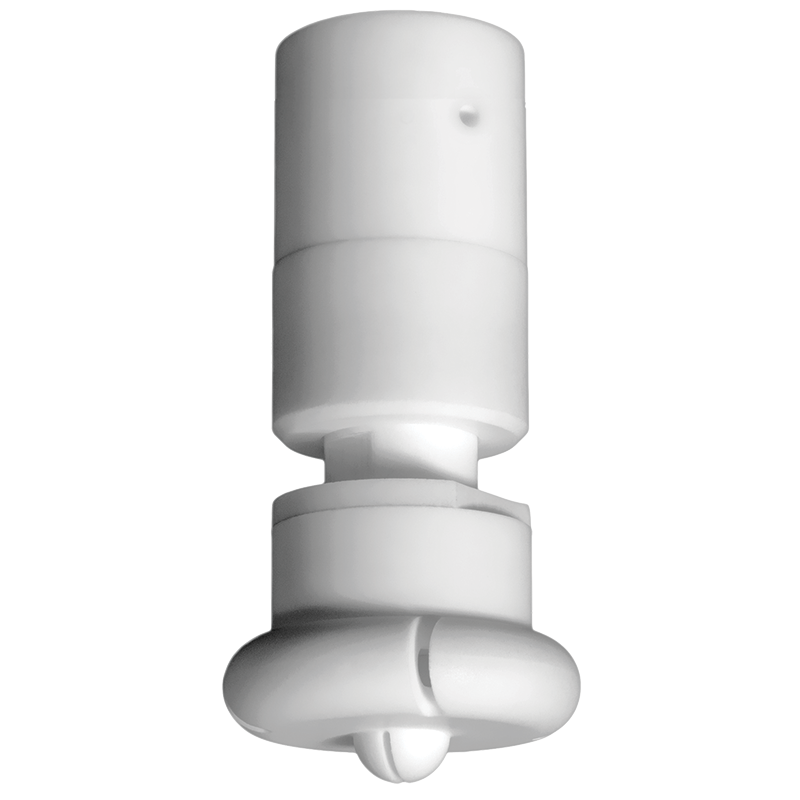

HydroWhirl® Mini PVDF

Reactionary Force Tank Cleaning Devices for Small Tanks

Soil Type: Light to Moderate

Cleaning Range: Up to 3.5 ft

Flow Rates: 3 to 9 GPM

Pressure: 10 to 60 psi

Min. Entry Diameter: 1.2"

Max Temperature: 194°F

HydroWhirl® Disc (HWD)

Powerful Submersible Rotating Tank Cleaner

Soil Type: Moderate to Heavy

Cleaning Range: Up to 25 ft

Flow Rates: 4.45 to 82.4 GPM

Pressure: 10 to 60 psi

Min. Entry Diameter: 1.7 to 3.3"

Max Temperature: 200°F

TW

Clog-Resistant Compact Tank Cleaning Devices

Soil Type: Light to Moderate

Cleaning Range: Up to 8 ft

Flow Rates: 3 to 163 GPM

Pressure: 10 to 400 psi

Min. Entry Diameter: .87 to 1.31"

Max Temperature: 550°F

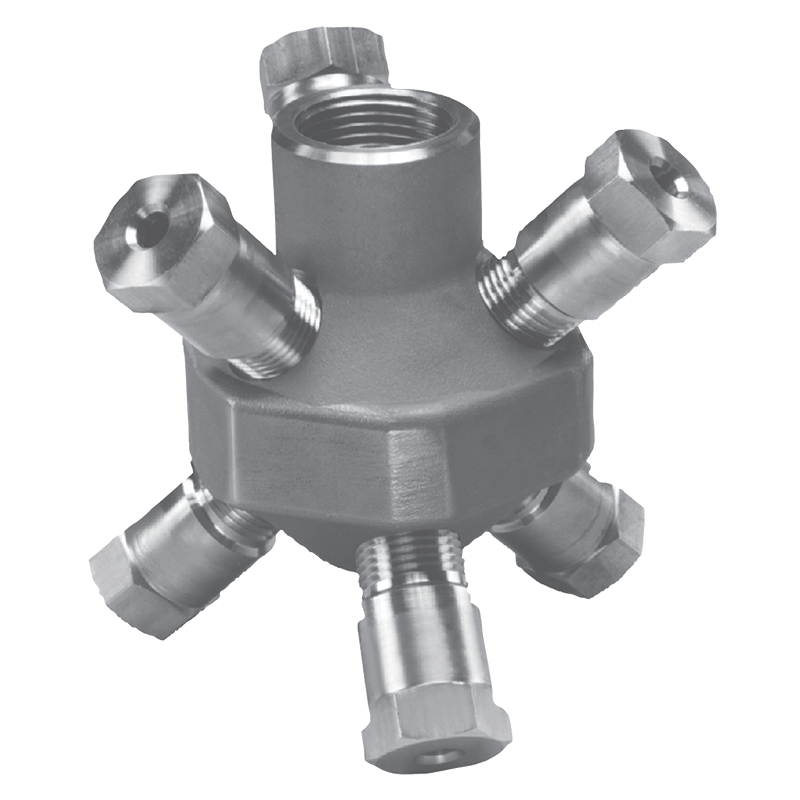

LEM

Clog-Resistant Stationary Tank Cleaning Devices

Soil Type: Light to Moderate

Cleaning Range: Up to 8 ft

Flow Rates: 4.2 to 157 GPM

Pressure: 10 to 100 psi

Min. Entry Diameter: 4.25 to 5.3"

Max Temperature: 550°F

Clump

Clog-Resistant Stationary Tank Cleaning Devices

Soil Type: Light to Moderate

Cleaning Range: Up to 10 ft

Flow Rates: 7.4 to 80.6 GPM

Pressure: 10 to 80 psi

Min. Entry Diameter: 5.75"

Max Temperature: 550°F

Common Uses & Industries

Bright Beer Tanks, Brew Kettles

Fermentation Tanks

Barrels, Totes and Drums

Cooking Kettles for Food Processing

Large Commercial Ovens and Freezers

Blending and Mixing Tanks for Personal Care Industry

Chemical Reactors

Underground Storage Tanks (UST) and Above Ground Storage Tanks (AST)

Oil and Gas Storage Tanks

Tanker Trucks and Railcars

Related Tank Cleaning Solutions

Read Our Case Studies

Tank Cleaning Solution Saves $144K In Maintenance Repairs for Food Processor

Soups and sauces cooked in kettles reach high temperatures, leaving residue caked onto the surface walls. The kettles must be cleaned and sanitized between batches to prevent cross-contamination. For these crucial applications, the right spray device will optimize cleaning and reduce downtime.

Read More

HydroClaw® Improves Tank Cleaning Efficiency and Resolves Maintenance Issues for Tomato Processor

Seeds, skins, pulp, stems, and grains in a recirculated water system can cause blockage in many tank

washing nozzle designs, inhibiting their ability to work correctly. Cleaning tanks and maintaining a

sanitary environment is essential to success in food processing and beverage industries. Problems

within these systems lead to loss of time, money, and resources – an unacceptable situation.

Read More

HydroWhirl® Poseidon® Prevents Maintenance and Clogging Issues for Chemical Processing Plant

Cleaning tanks that contain corrosive materials can be problematic. The corrosion-resistant materials used

to make the vessels are not usually ideal for manufacturing tank cleaning nozzles. When the environment is

corrosive to even the highest grade steels, tank cleaning solutions are limited – particularly in larger tanks

where rotary tank cleaners are required.

Read More