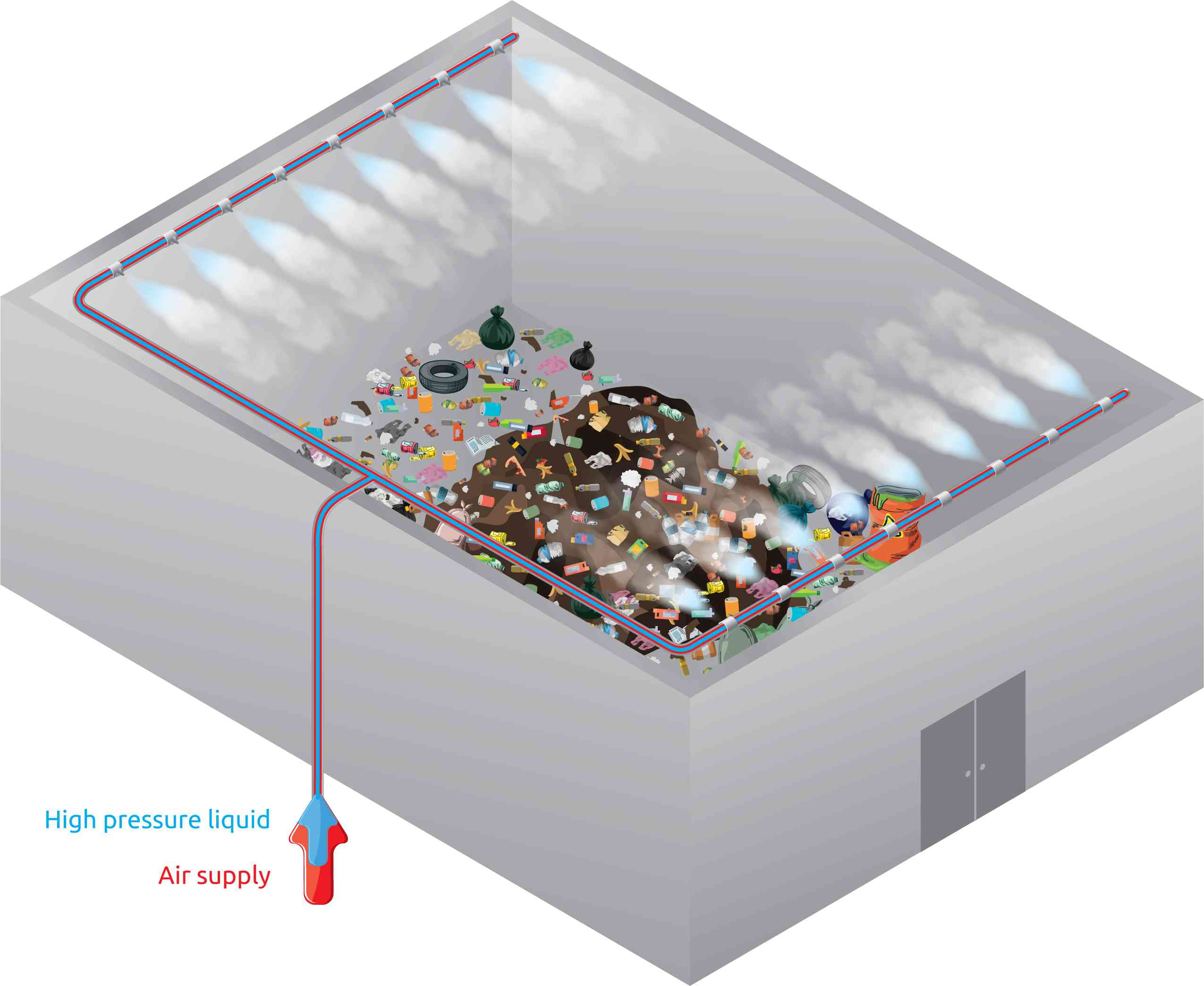

There are three categories of treatments that can spray through nozzles to control the odor: coverants, deodorants, and absorbents. These treatments are used in open-type or packed bed-type scrubber systems.

- Coverant is a better-smelling substance sprayed to mask or hide the bad odor.

- Deodorant is a liquid used to chemically change or break down the aromatic molecules in an odoriferous area or air stream, effectively neutralizing them.

- Absorbent is a liquid that absorbs the bad odor of a foul-smelling gas stream into the liquid, reducing the potential odor of the remaining gas. Water can often be used as an absorbant liquid.

In open-type scrubber systems, BETE misting and air atomizing nozzles are generally the most effective for odor control applications based on the fine drop size they produce, increasing the surface area to react or absorb the odor to be controlled. In packed bed-type scrubber systems, BETE axial whirl nozzles are generally the most effective for achieving even distribution over the packing surface and ensuring no gas bypass through the packing.

Common Uses & Industries

Important factors to consider:

Applicable design specifications and requirements

- Open type scrubber or packed bed type scrubber

- Coverant, deoderant, or absorbant

Process pipe/duct/vessel size, velocity, pressure, temperature, and fluid composition

Required materials of construction for corrosive environments

Spray media density and viscosity

Required spray media flow rate

Available pressure drop (∆P) across the nozzle

- ∆P = supply pressure at nozzle inlet – process pressure outside nozzle