Improve Your Process With Spray Technology Fabrications

Use BETE spray lances, injectors, and quills for tank cleaning, gas cooling and conditioning, NOx control, chemical injection, or wash water injection.

Our spray injectors create stable conditions for the safe and efficient operation of downstream plant components. Avoid wall wetting, pipe corrosion, costly repairs, and unscheduled outages from occurring with spray injection solutions from BETE.

Spray Lances and Injectors

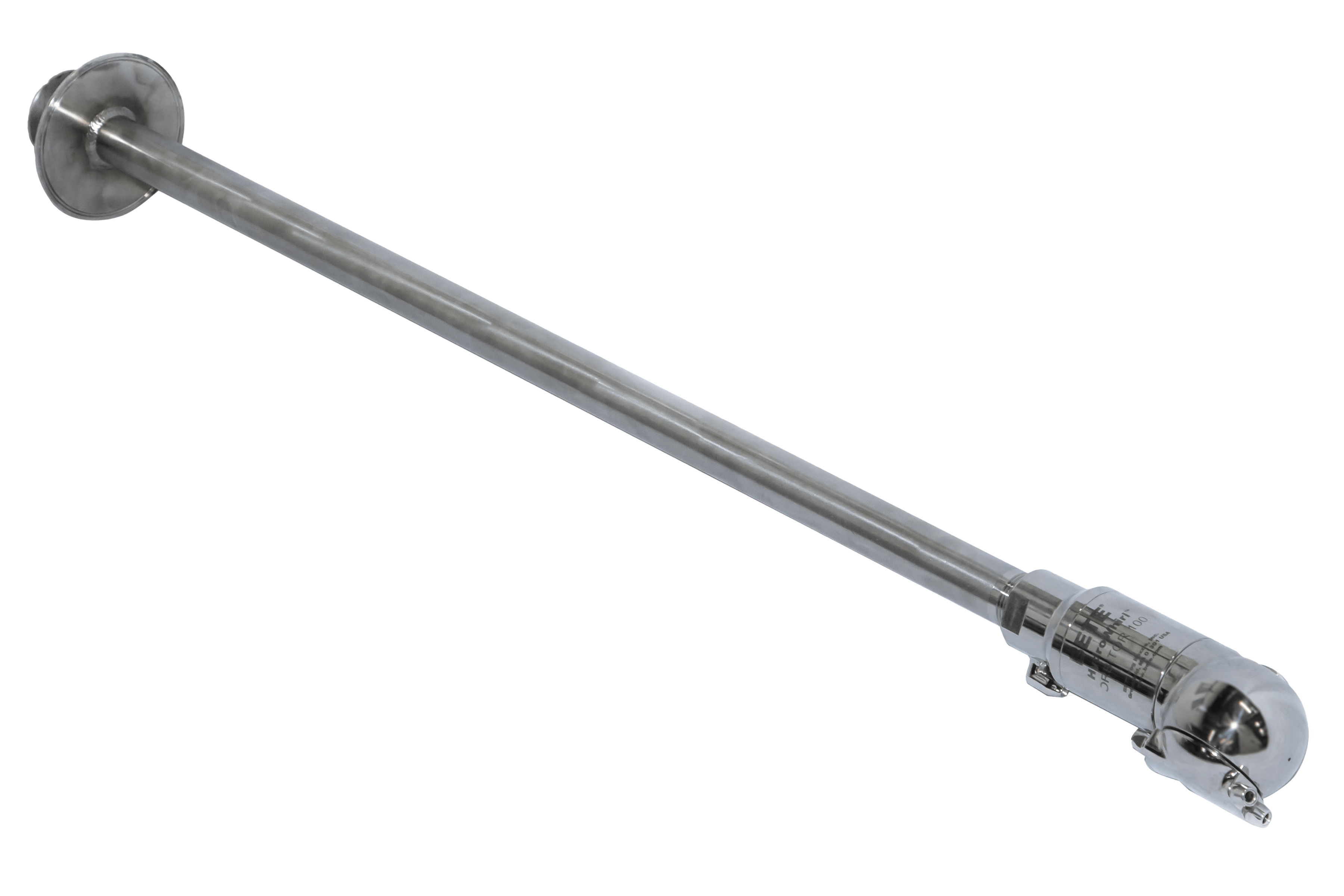

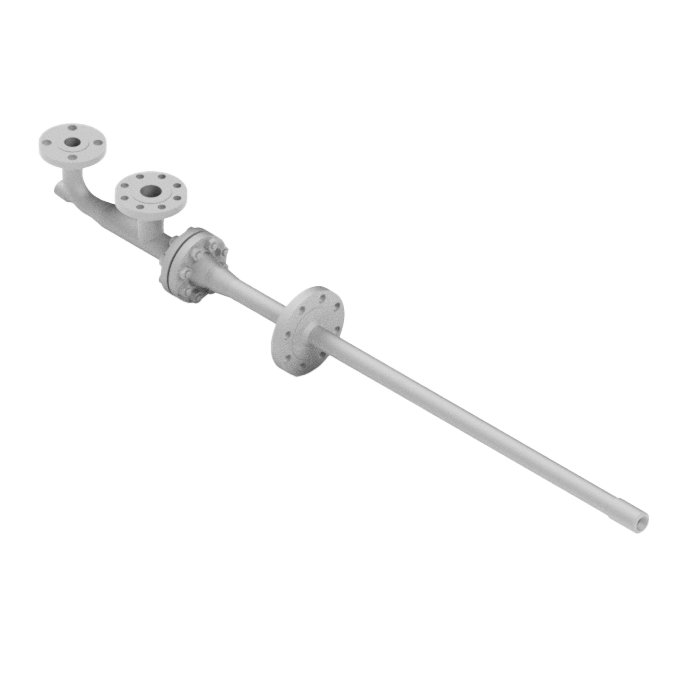

Tank Cleaning Lances

- Pipe & Flange

- Stationary or Retractable

- Used for precise placement inside a vessel

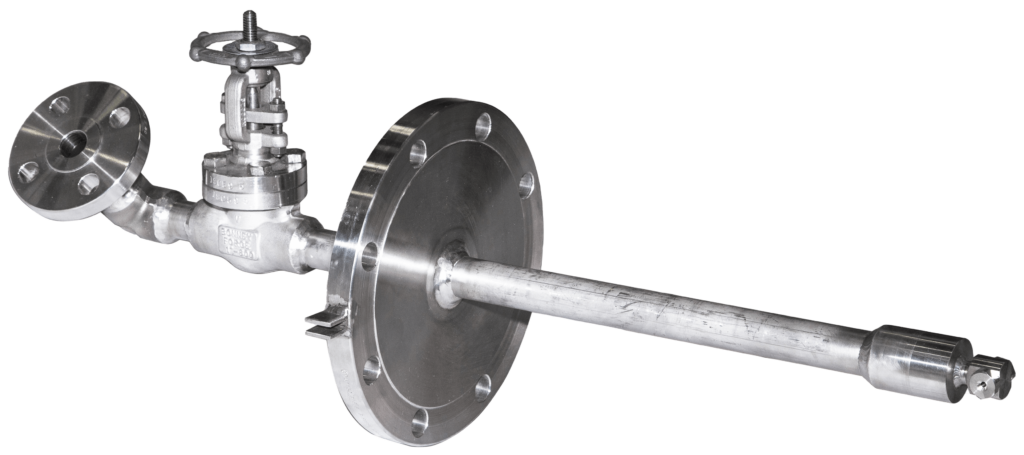

Spray Lance Injectors

- Drop-in Solution

- Single or Two-Fluid Air Atomizing Spray Nozzles

- Complex Code Compliant Fabrications

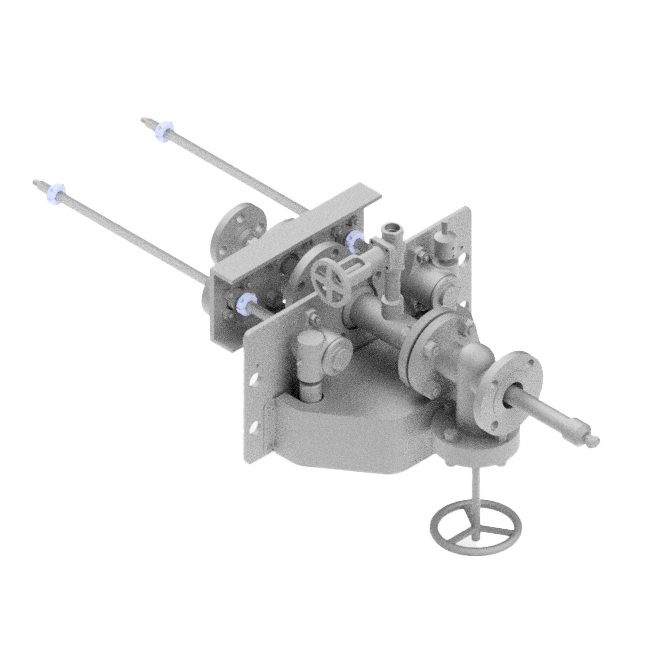

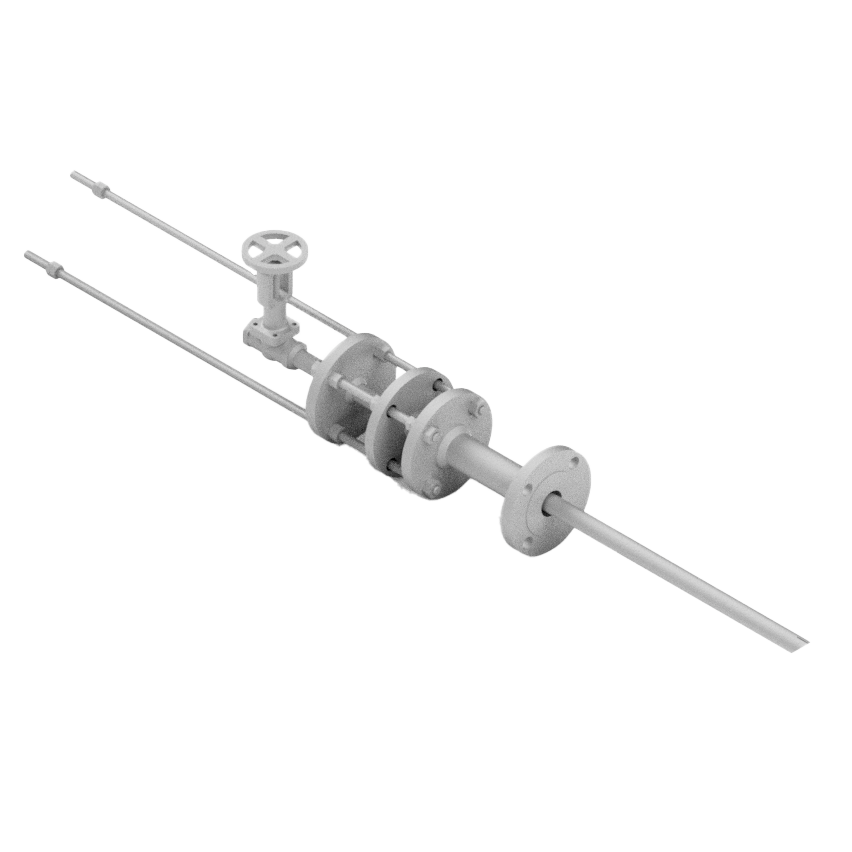

Retractable Lances

- Inspect & Service Nozzles Without Disrupting Process

- Options include lance, isolation valve, drain valve, and retraction mechanism

Request a Lance

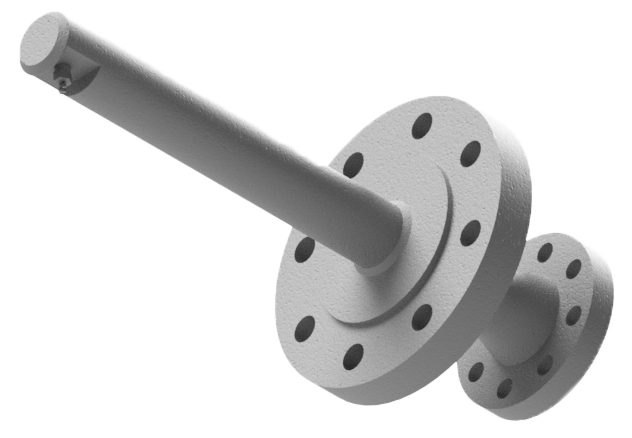

Injection Quills

Injection Quills

Retractable Quills

Why Use Retractable Lances?

Retractable lances allow you to withdraw your nozzle, isolate it from the process, and remove it entirely for servicing without taking your process offline. Once you have serviced, cleaned, or inspected the nozzle –reattach it to the system, open the isolation valve, and insert it back into the process.

Such features are often critical for petrochemical facilities where process outages are costly. For example, specific applications involved in petroleum production contain very corrosive particles. The ability to remove the nozzle for replacement while keeping the process online offers tremendous cost savings.

For smaller retractable lances, maintenance can manually insert and withdraw the lance pipe. BETE offers a robust retraction mechanism that effortlessly moves the lance from extended to inserted and back for larger sizes or any size where automation or ease of use is required. A simple cordless drill can power the unit, making this design a favorite for maintenance crews. The mechanism is flexible in its configuration, allowing alternate electric, pneumatic, or hydraulic power sources to drive the unit.

Design, Fabrication, & Testing Process

Common Materials

- 310, 316, 321, 347

- C-276, C-22, 625, 825

Manufactoring Code

Compliance

View our certifications and approvals.

Common Design Requirements

- Boiler External Piping (PP Authorization)

- Nonboiler External Piping