Nozzles are essential components that produce different spray patterns based on their design. Understanding these patterns can help you choose the right nozzle for your spray application. In this article, we’ll explore five common types of spray patterns and their uses.

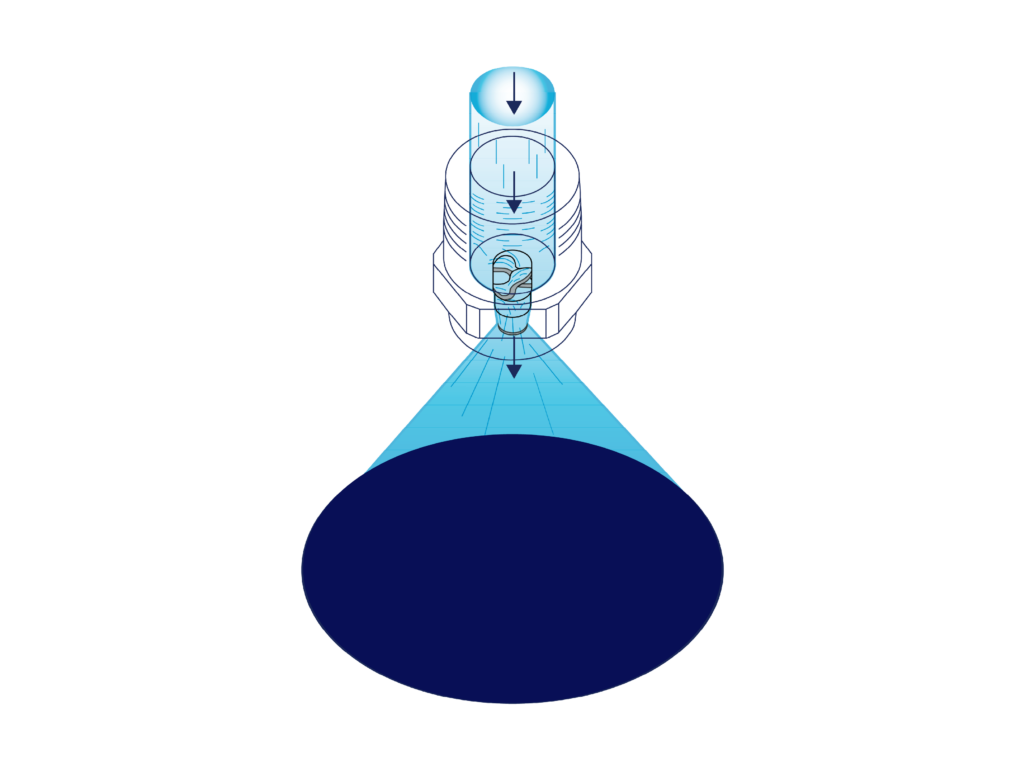

Full Cone Spray Pattern

Full cone spray patterns disperse liquid in a conical shape, creating a circle of spray when it contacts a surface. These spray patterns produce medium to large-sized droplets, ideal for cooling, quenching, and washing. A full cone nozzle pattern provides great coverage results if you are looking for even distribution over a packed bed.

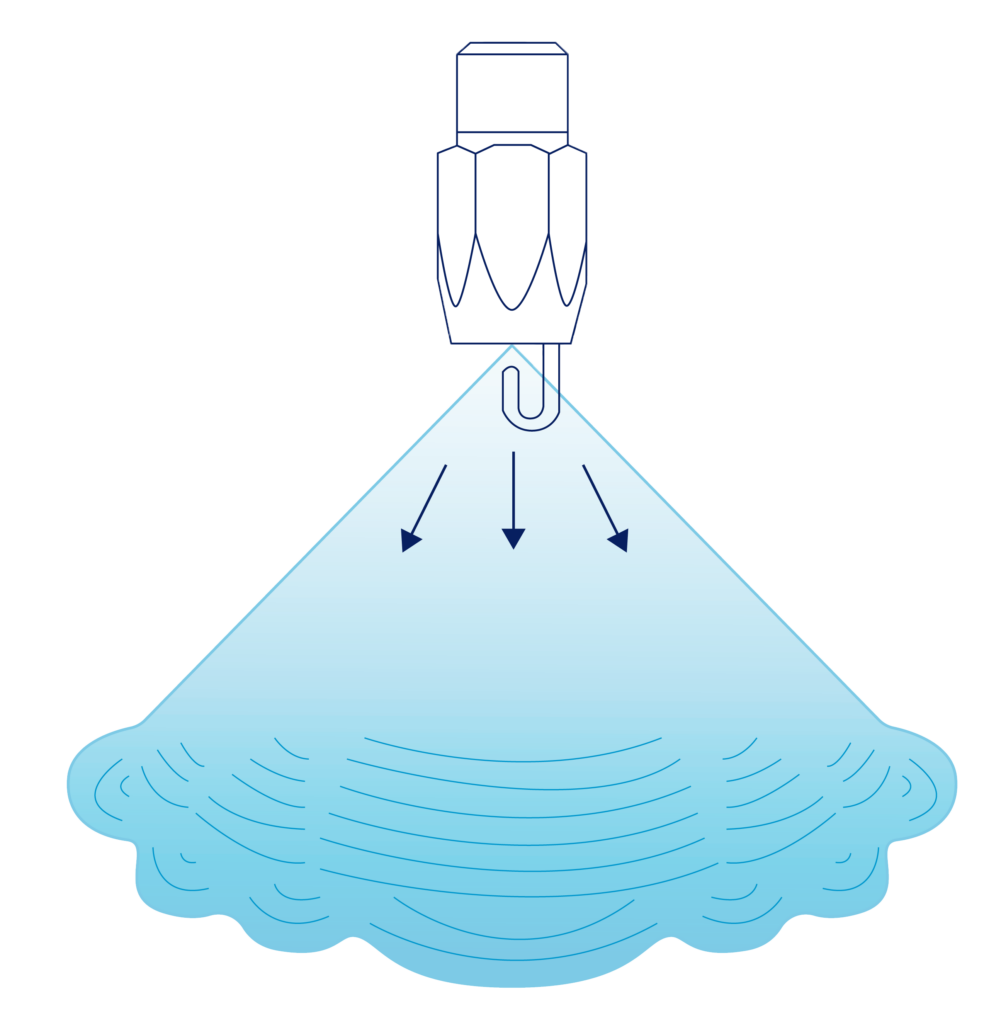

Hollow Cone Spray Pattern

Hollow cone spray patterns produce a ring-like spray with droplets concentrated around the outer perimeter. The droplets formed are much smaller than a full cone spray pattern. Hollow cone patterns produce a good interface between air and the surface of the droplets, making them ideal for gas cooling, gas scrubbing, and dust control.

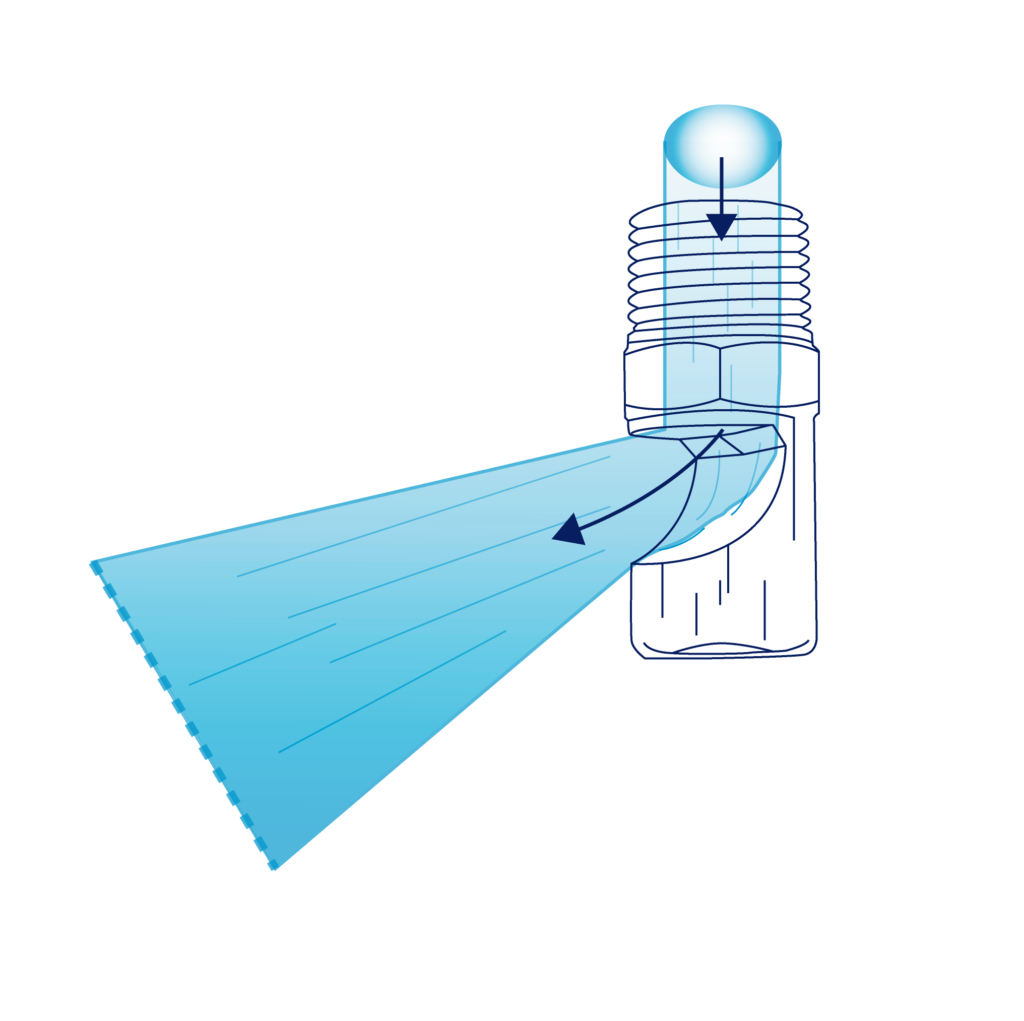

Fan Spray Pattern

Fan spray patterns are designed for effective impact and even distribution. Two design styles are available to choose from depending on your application: axial and deflected.

Axial-style nozzles disperse liquid directly through the orifice, where the spray widens as it moves outward, creating a uniform distribution. Axial fan spray patterns are best for conveyor belt washing, coating, or wetting applications.

Deflector-style nozzles project the spray off of an external surface. They have a round orifice with a larger free passage than the axial-style fan nozzle. Deflector fan spray patterns provide high-impact force while generating relatively low flow rates and are often used in fire suppression applications.

Misting Spray Pattern

Misting spray patterns are made of very fine droplets using liquid pressure only, without compressed air. The droplets are typically small enough that buoyancy is significant compared to gravity, allowing drops to appear to float. Misting spray patterns are ideal for cooling, humidification, or when complete evaporation is required.

Air Atomizing Spray Pattern

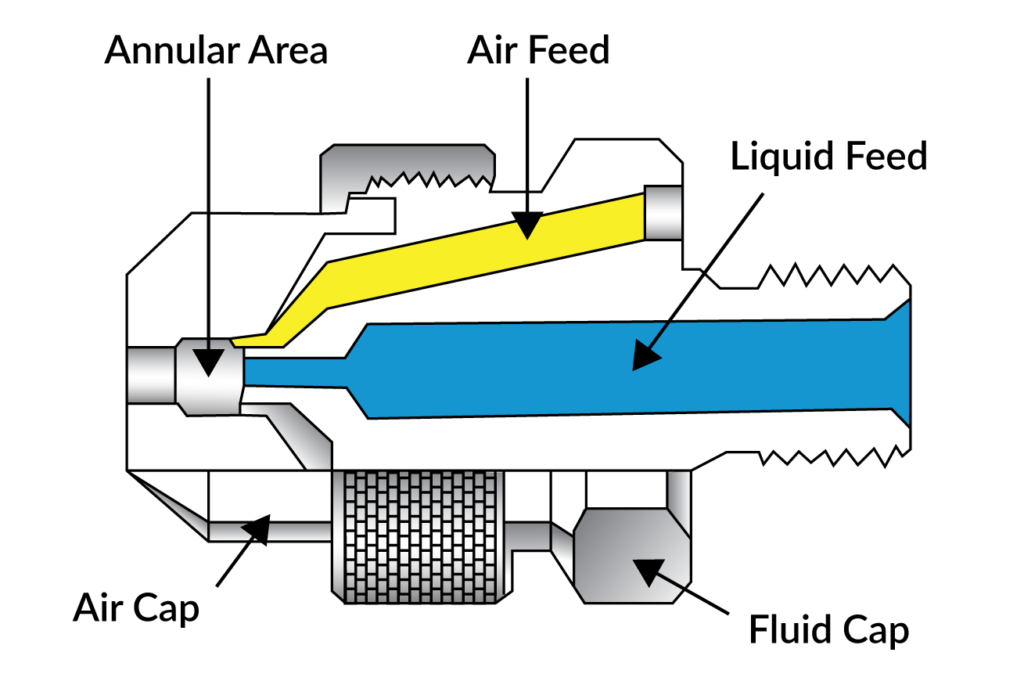

Air atomizing spray patterns produce finely atomized sprays by combining liquid and compressed air at low pressures. Depending on the nozzle design they can create either a fan or cone spray pattern. Air atomizing nozzles use internal and external methods for mixing fluid and air.

For internal mixing, liquid and air streams come together inside the nozzle and are mixed and exited through the same orifice. Changes in airflow will affect the liquid flow because the streams are not independent.

External mixing allows for independent control of air and liquid flow rates because the air and liquid streams exit the nozzle independently through each orifice. External designs allow for precise fluid metering.

Air atomizing spray patterns work best for coating, humidifying, lubricating, moistening, gas cooling, and conditioning applications.

Learn More About Choosing The Right Spray Pattern Type For Your Application

Whether you need even distribution, effective impact, or fine mist, there’s a spray pattern designed to meet your specific needs. For guidance in selecting the ideal pattern for your spray application, reach out to our Applications Engineering department.

With over 70 years of experience in the nozzle industry, we excel at optimizing your spray processes for peak performance, reliability, and efficiency.