Thank you for downloading our white paper

Click here to view

We hope you find the insights useful as you explore strategies for improving gas cooling performance. If you’d like to discuss how BETE can help with your application, please Contact a Spray Expert.

Learn More about the Author

Read an interview with Daniel deLesdernier, BETE's Manager of Andvanced Spray Engineering Services here.

ADVANCED SPRAY ENGINEERING SERVICES

Understanding nozzle performance and how a spray behaves in your process is critical. When information in our catalog is not enough, BETE's resources and experience can help you with nozzle selection, solving existing spray problems, or designing a new spray system or nozzle process.

Related Industries

Read Our Case Studies

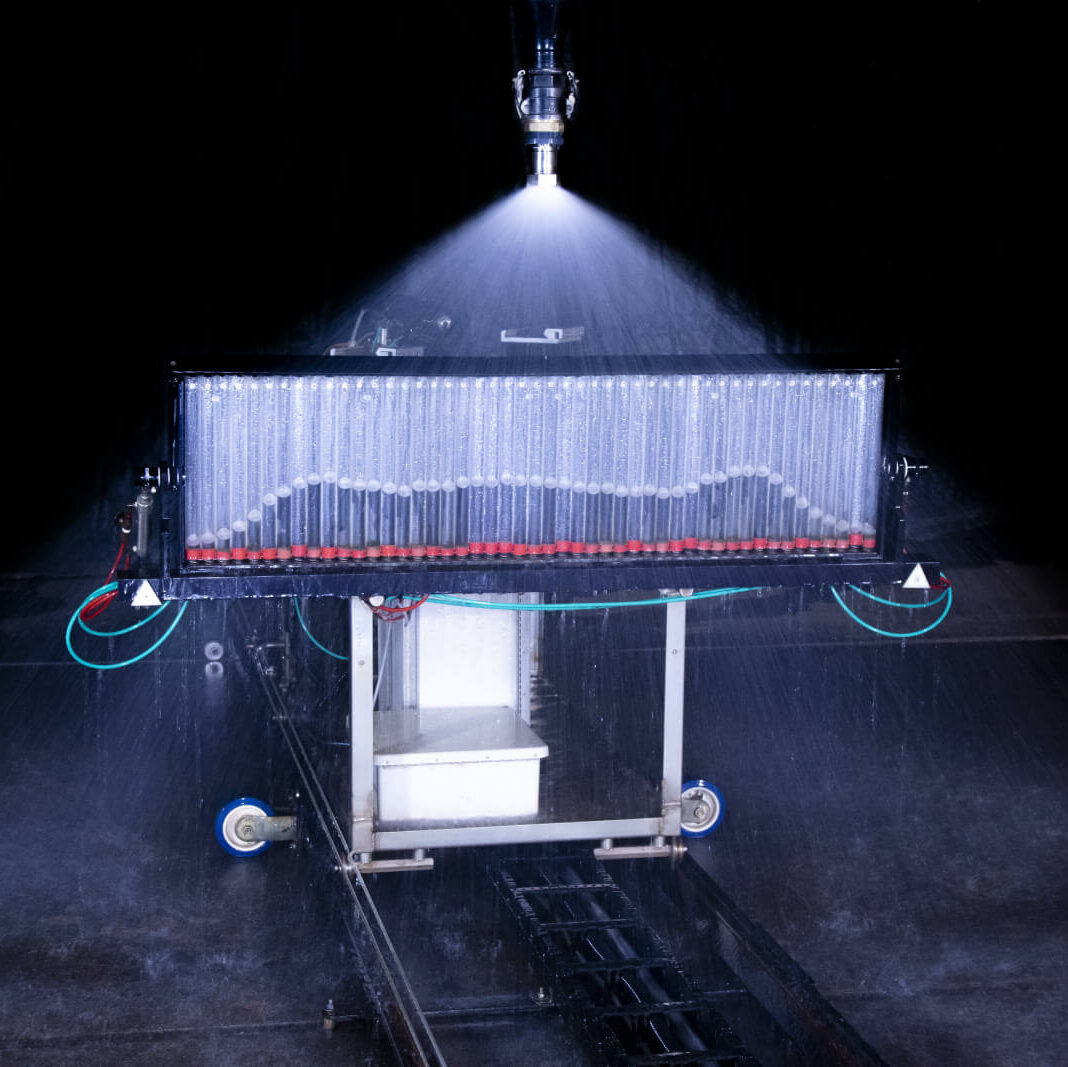

Automated Spray System for Chemical Processing Enhances Gas Cooling Performance and Reliability

A demineralized water injection system is needed to quench calciner furnace exhaust gas upstream of dust

collection equipment at a chemical processing plant during the manufacture of specialty catalyst. Spray

nozzles need to produce small droplet sizes to achieve complete evaporation, which requires pumps for

high-pressure water supply, controls, and instrumentation to regulate and monitor the gas temperature.

Read More

HydroWhirl® Poseidon® Prevents Maintenance and Clogging Issues for Chemical Processing Plant

Cleaning tanks that contain corrosive materials can be problematic. The corrosion-resistant materials used

to make the vessels are not usually ideal for manufacturing tank cleaning nozzles. When the environment is

corrosive to even the highest grade steels, tank cleaning solutions are limited – particularly in larger tanks

where rotary tank cleaners are required.

Read More

SpiralAir® Nozzle Significantly Reduces Air Consumption Usage in Flue Gas Cooling

Cooling of exhaust gases from the Electric Arc Furnace (EAF) is critical to controlling temperatures of

the gas in the ductwork as it enters the baghouse to prevent a fire. Air atomizing nozzles are ideal for

cooling the gases because they produce very fine droplets, but air consumption can be high and costly

if the proper nozzle is not selected.

Read More