Patternator

Spray Laboratory Instrumentation

Liquid distribution is critical to many processes. For example, a nozzle in a packed-bed scrubber needs to distribute the liquid evenly over the packing. The BETE Video Patternator is a system that enables rapid and accurate analysis of the volumetric distribution of liquid in the spray volume.

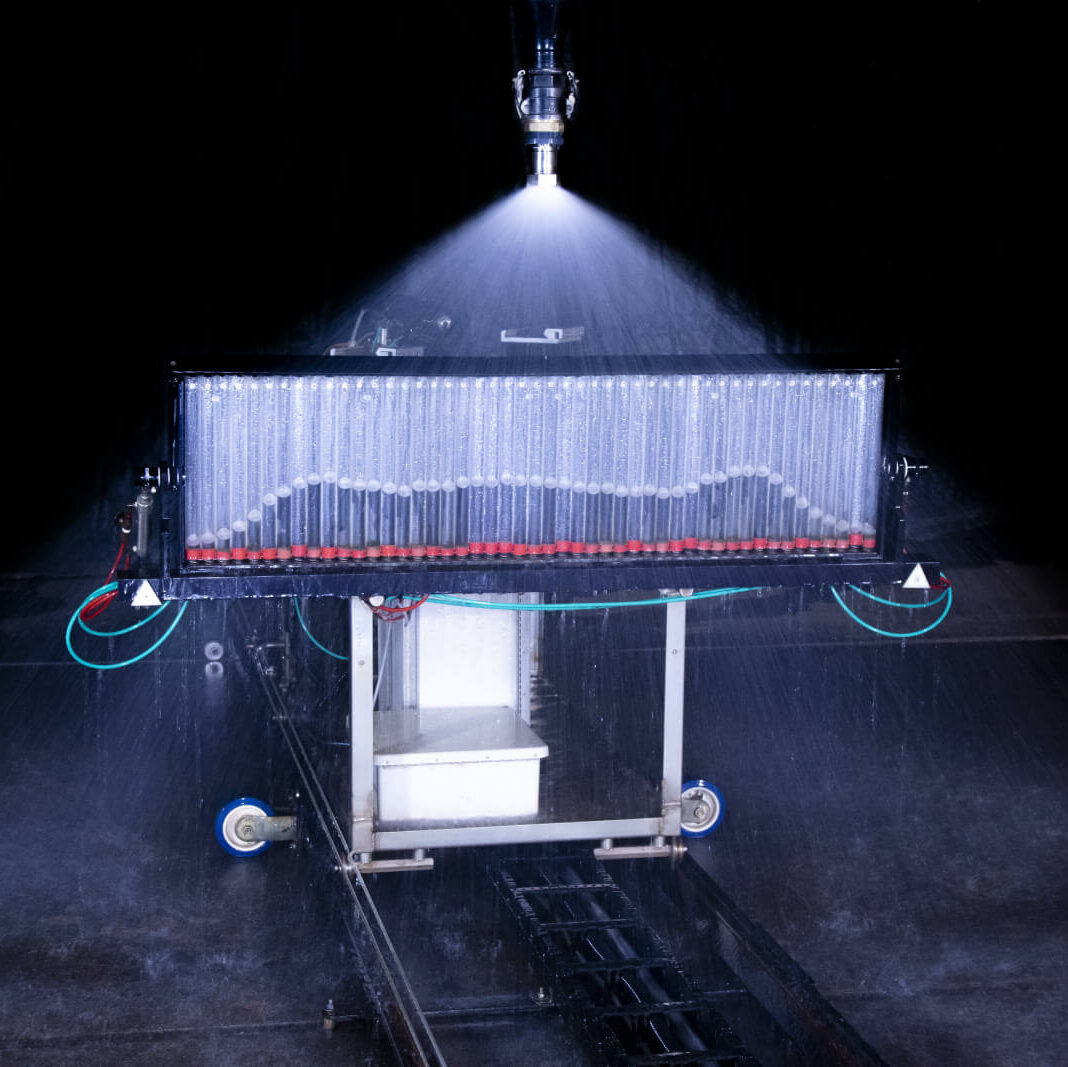

BETE Video Patternator

The system utilizes a standard collection device consisting of a linear array of plastic tubes. This array is mounted on an X Y Z positioning device and placed beneath the spray nozzle. When the correct nozzle operating pressure is reached and has stabilized, a pneumatic cylinder opens a cover, allowing the tubes to fill with liquid. Each tube contains a white ball that floats on the liquid collected within, providing a visual indication of the liquid height.

A video camera is aimed at the Patternator while the nozzle is spraying. The image is digitized, and custom shape recognition and timing software developed at BETE locates the center of each ball above the standard baseline. By scanning the spray pattern in a series of individual patterns, the system can handle spray diameters over 6m. We calculate the spray density, effective, and volume-based spray angles from this information.

The software presents the liquid flux data with several vital summary statistics in graphic form. Total Coverage refers to the full diameter across the distributed water during the test. For example, if 36 tubes contained water after the test, the total coverage diameter is 36* (tube diameter). Our tubes have a square cross-section and are 25.4 mm from one another. When the height of the nozzle above the Patternator tubes is known, one can find the total spray angle using trigonometry.