TANK CLEANING LANCES

Request a quote

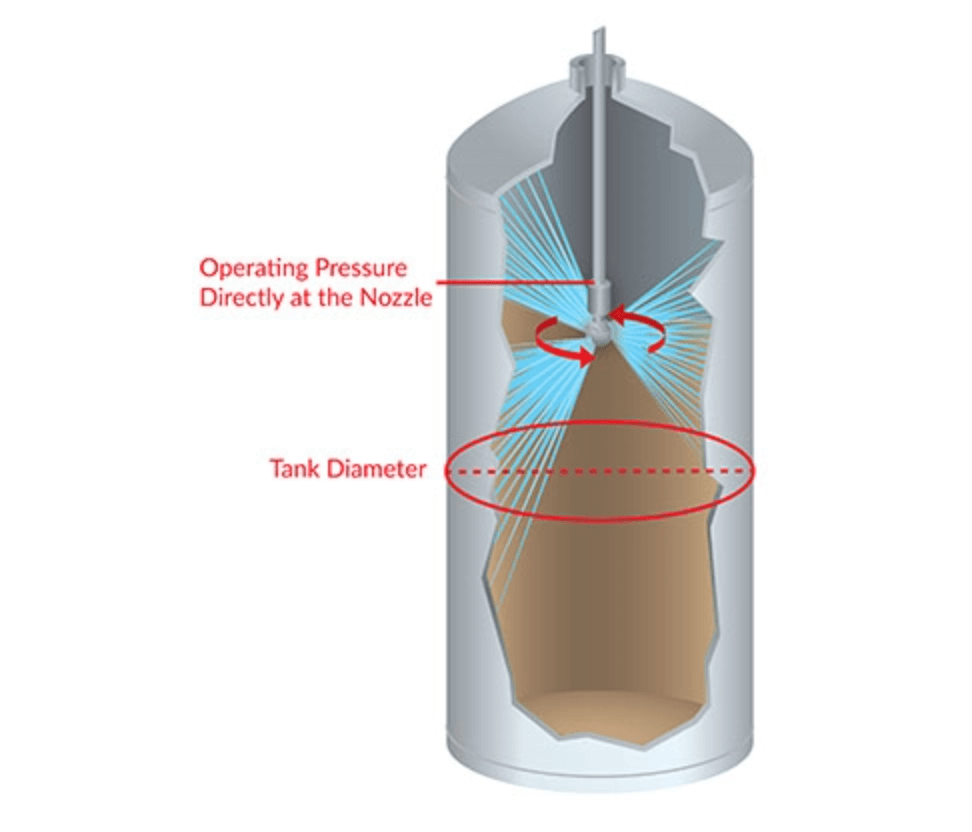

Symmetrical Tri-Clamp Lance with HydroWhirl® Orbitor 100 tank cleaning machine

Optimize Nozzle Placement & Improve Tank Cleaning Efficiency With Tank Cleaning Lances

BETE tank cleaning lances provide a custom-engineered solution for optimal nozzle placement inside a tank. We design and fabricate all lances at our facility to ensure close coordination through every manufacturing phase.

We are capable of symmetrical and asymmetrical designs and can add a retractable feature for Clean-In-Place (CIP) or Clean-Out-of-Place (COP) applications. We can fabricate a customized lance for any BETE tank cleaning nozzle. BETE welders can provide assemblies manufactured to ASME B31.3 Code for Process Piping and other applicable ASME Codes/Standards in various materials.

Equipment & Tank Cleaning Brochure

Download PDF

Tank Cleaning Spray Technology Line Card

Download PDF

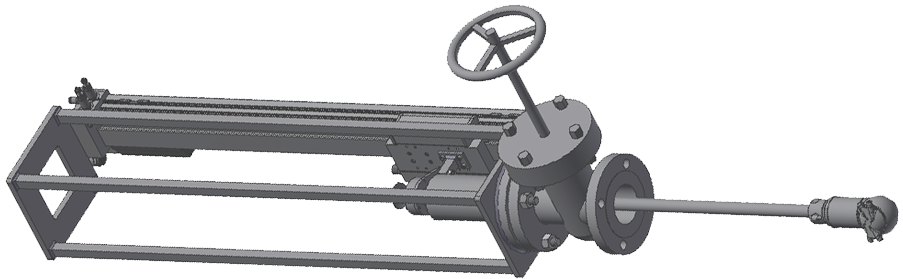

Retractable Tank Cleaning Lances

Retractable lances allow you to withdraw your nozzle and isolate it from the process so that it does not come in contact with the product. Nozzle maintenance is easy with retractable lance because it can be entirely removed for servicing without taking your process offline. Once you have serviced, cleaned, or inspected the nozzle – reattach it to the lance.

Considerations For Using Tank Cleaning Lances

Several factors explain why a tank cleaning lance may improve your cleaning process. Our engineers can evaluate your new or existing process to recommend solutions for achieving optimal cleaning performance and reliability. Discover why you would use a tank cleaning lance using the slide arrows below.

Request A Lance

Tell us about your application by downloading one of our forms

Custom Lance Application Information Request Form

Download PDF

Retractable Lance Information Request Form

Download PDF

Related Tank Cleaning Solutions

Case Studies

Automated Spray System for Chemical Processing Enhances Gas Cooling Performance and Reliability

A demineralized water injection system is needed to quench calciner furnace exhaust gas upstream of dust

collection equipment at a chemical processing plant during the manufacture of specialty catalyst. Spray

nozzles need to produce small droplet sizes to achieve complete evaporation, which requires pumps for

high-pressure water supply, controls, and instrumentation to regulate and monitor the gas temperature.

Read More

FlexFlow® Spray System Reduces Material Waste With Precision Coating for Frozen Pastry Manufacturer

Filo dough moving along an assembly line is filled with various ingredients, hand-rolled, and packaged. Before

rolling the dough, palm oil is hand-brushed by two linemen to act as the “glue” that holds the pastry together. The

manual application creates inconsistencies in the product, variation in nutritional content, excessive use of oil,

and uneven coverage – adding to the overall cost of production.

Read More

Prominent Winery Saved From Nozzle Clogging, Unwanted Maintenance, and Downtime

Even with a preliminary rinse before the cleaning process, leftover grape debris in the fermentation tanks such

as seeds, stems, and skins remain.

Read More