DESIGN FEATURES

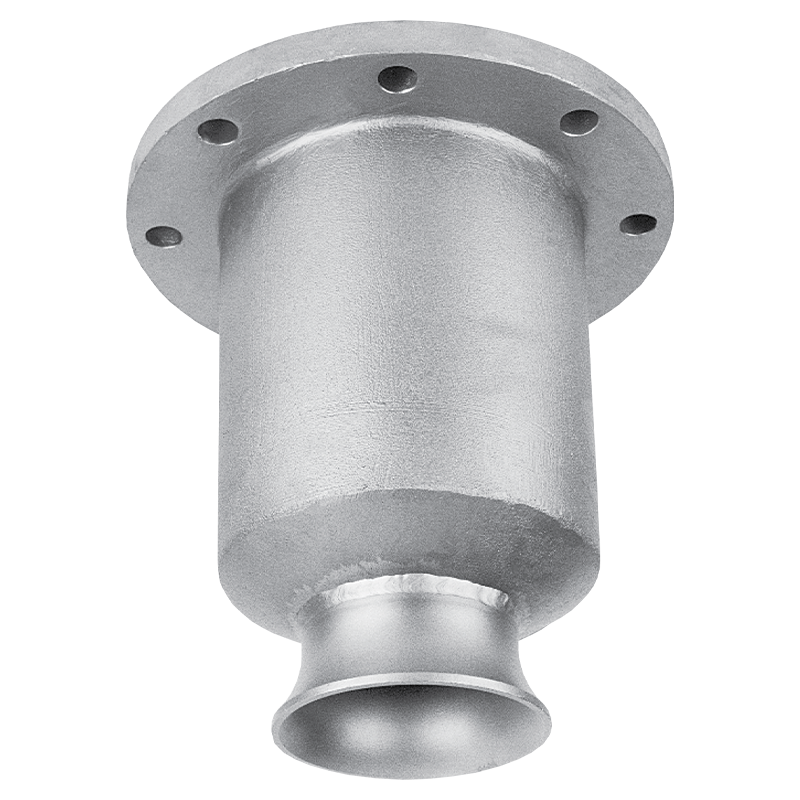

One-piece body with integral vanes

Flanged connections available

Extremely high flow rates

Durable construction

HOW SPRAY PATTERN IS ACHIEVED

Atomization is achieved by the water being spun inside the nozzle and then exiting an orifice

Produces medium to coarse droplet size

More uniform pattern than spiral nozzles

Available Spray Angles

60 - 120°

Flow Rate Range

217 to 11000 gpm

Available Connection Types

- Pipe: 6, 8, 12

- Connection Methods: Thread (NPT, BSP, Male, Female), Flange (150#)

Material

316

Flow Rates, Spray Angles, Connections

Full Cone

Select a nozzle number below for performance graph, drawings, and to request a quote.

Flow rate (gpm/lpm) is calculated at differential pressure (psi/bar).

Nozzle Number

Connection Sizes

Spray Angles

Flow Rate (gpm) @ Differential Pressure (psi) (Density: 1 SG)

1 psi

3 psi

5 psi

10 psi

20 psi

40 psi

217

360

455

626

861

1180

240

398

503

692

952

1310

338

560

709

975

1340

1840

393

651

824

1130

1560

2140

458

759

960

1320

1820

2500

515

854

1080

1490

2040

2810

605

1000

1270

1740

2400

3300

846

1400

1770

2440

3360

4620

960

1590

2010

2770

3810

5240

1030

1700

2150

2960

4070

5590

1090

1800

2280

3130

4310

5930

1210

2000

2530

3490

4800

6600

1330

2200

2780

3830

5270

7250