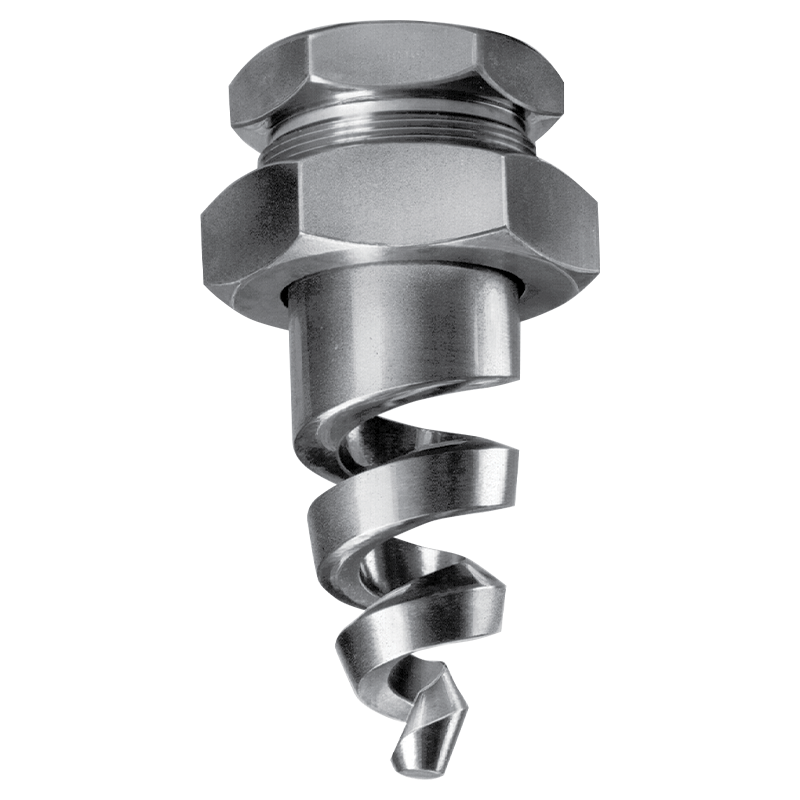

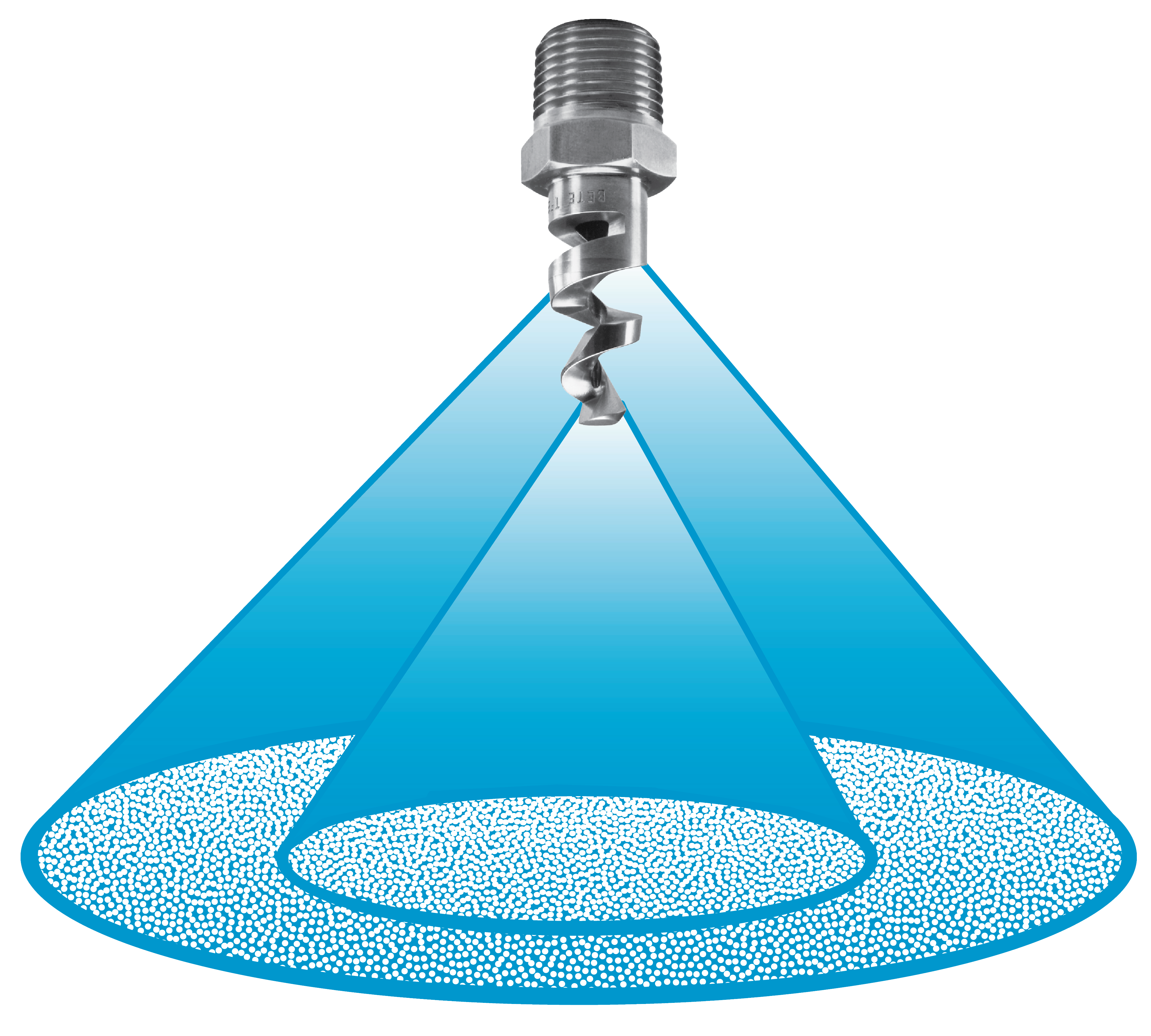

The original BETE spiral nozzle design is also called a pigtail, corkscrew, or helix nozzle. The spiral produces relatively coarse droplets surrounded by wider bands of relatively fine droplets. Ideal for quenching, scrubbing, and evaporative cooling.

Configure Your Exact Spiral Spray Nozzles

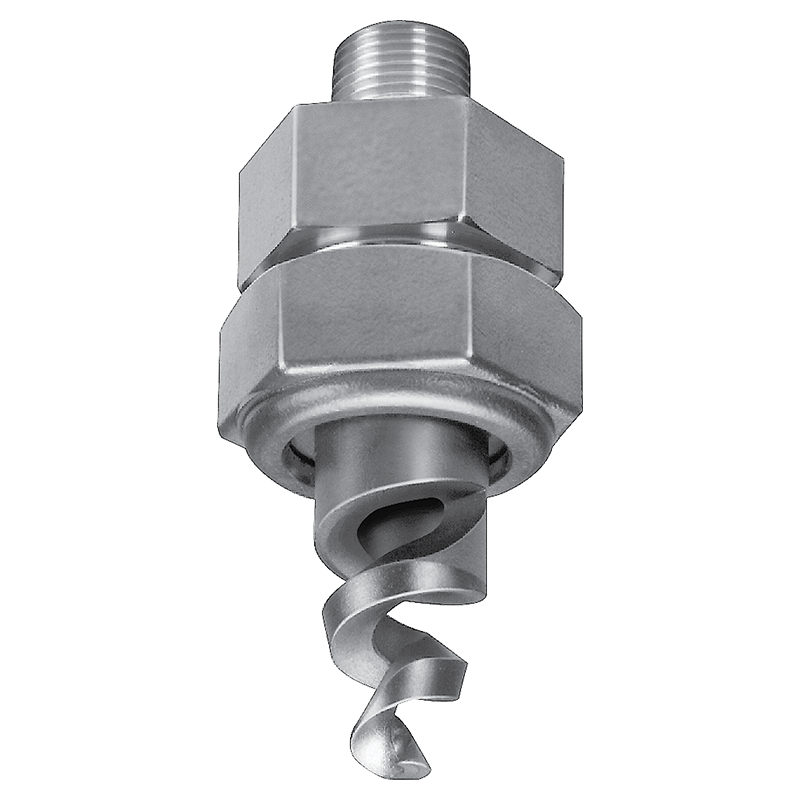

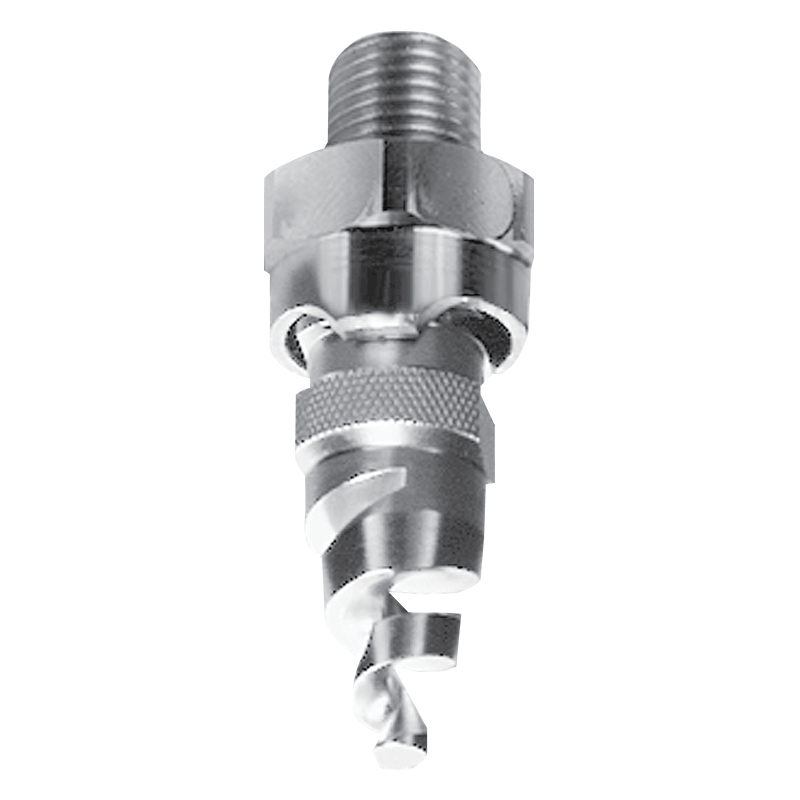

The Original BETE TF Spiral Nozzle Design

Discover the TF spiral nozzle invented by BETE. The durable one-piece design of the TF is resistant to clogging and has a high discharge velocity. Spiral nozzles feature efficient spray performance for finer atomization. The TF offers a wide range of flow rates and spray angles.

Customers trust the reliability of BETE’s TF spiral nozzles for optimal spraying in quenching, scrubbing, and evaporative cooling applications.

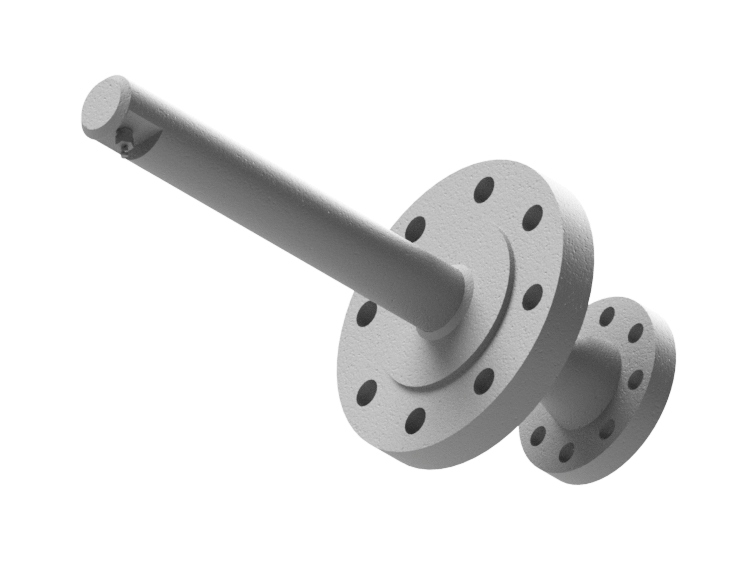

Improve Your Process with Spray Technology Fabrications

Choose your spiral nozzle, and BETE can custom design and fabricate spray headers, spray lances, and injectors for precise placement to optimize your spray process.

Fabrication is BETE’s specialty, from complex ASME Code compliance to simple flush pipe assemblies.

Spiral Nozzles

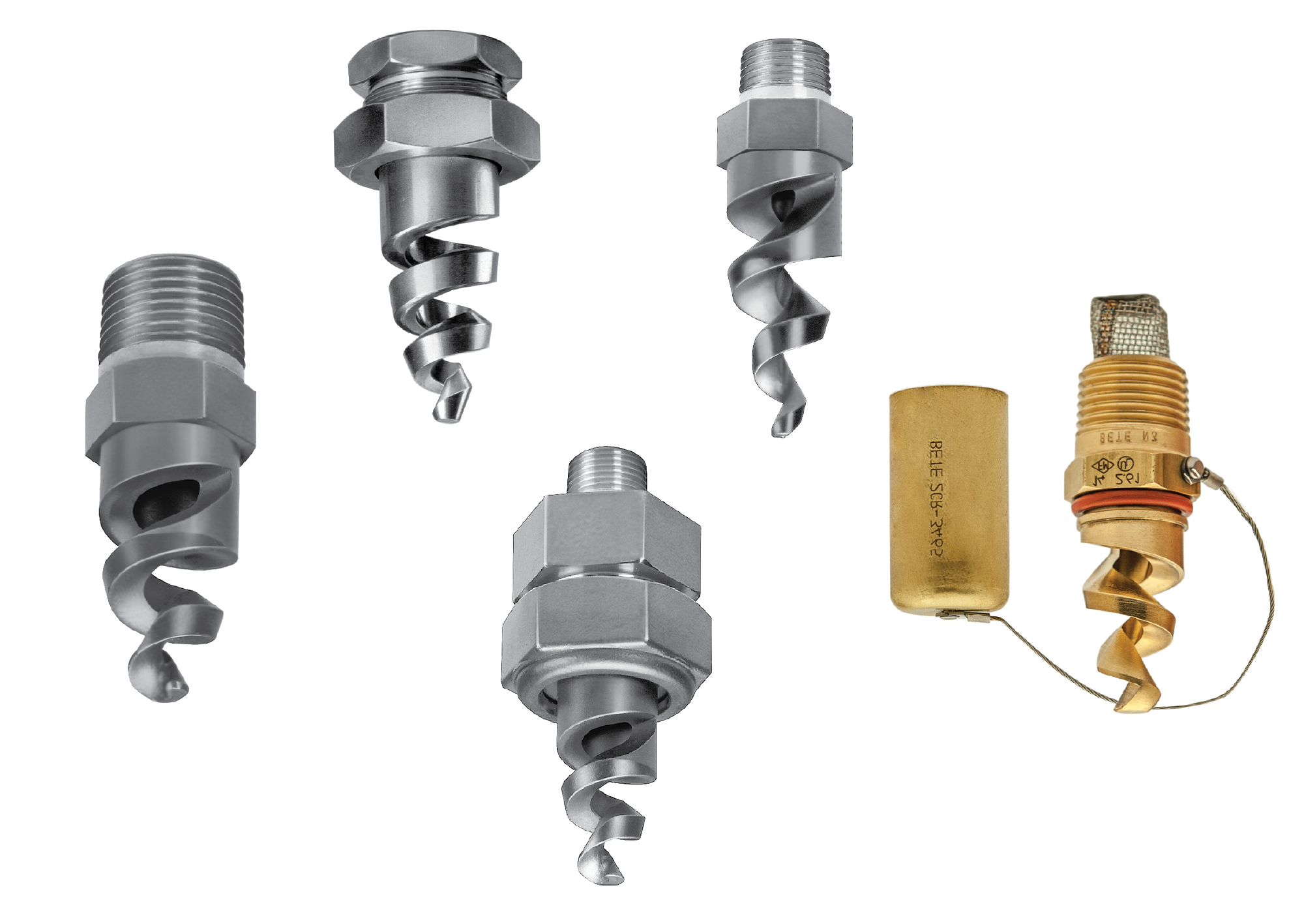

TF Full Cone & Hollow Cone Spiral Nozzles

ST Abrasion Resistant Spiral Nozzles

EZTF Quick Connect Full Cone or Hollow Cone Spiral Nozzles

Spiral Spray Nozzles

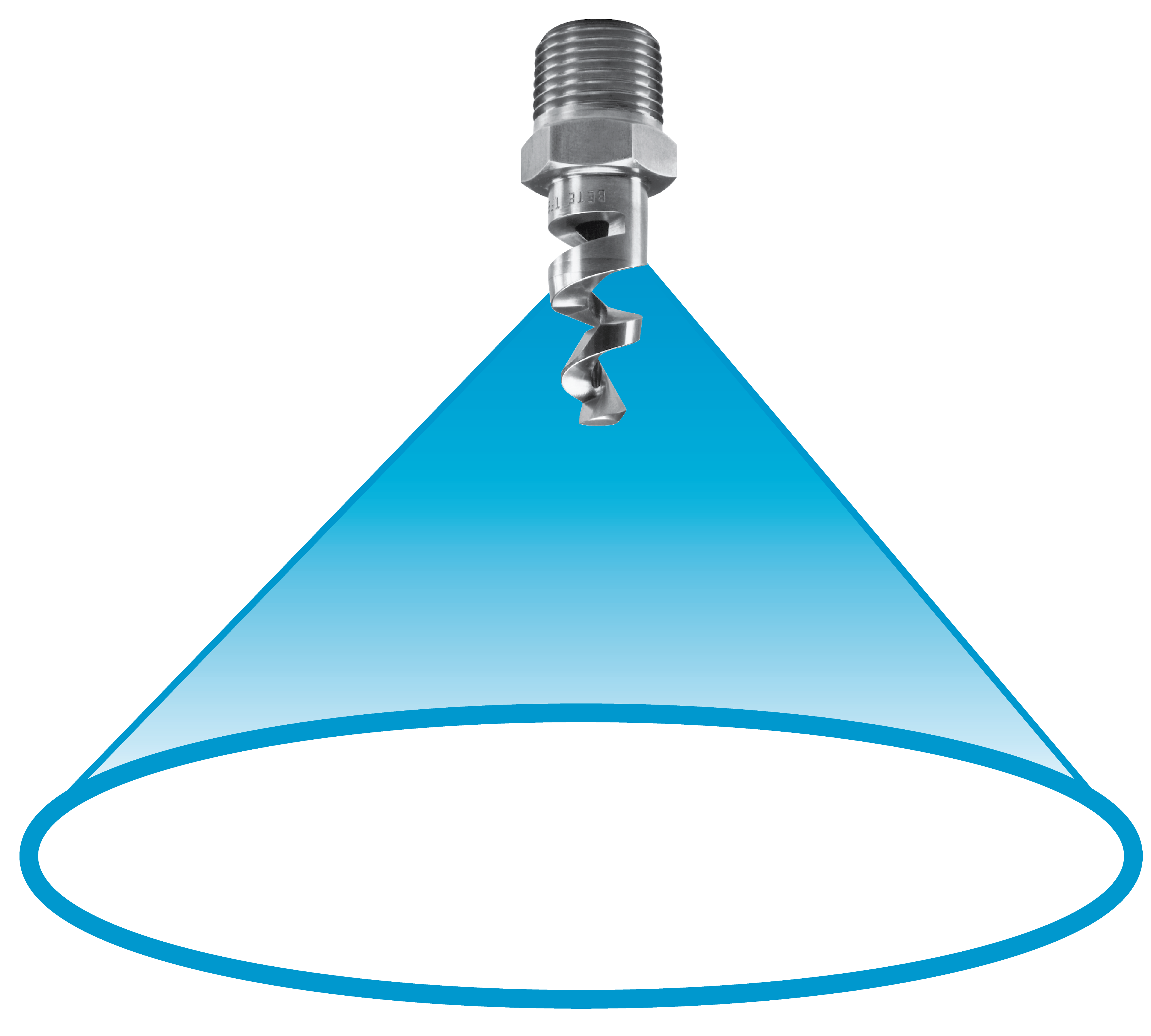

The spray pattern of the spiral nozzle is formed by the fluid shearing along with the turns of the spiral, which produce multiple concentric cones. These cones form 2 to 3 bands of relatively coarse droplets, surrounded by wider bands of relatively fine droplets.

Spiral Full Cone

- Larger coarse droplets are formed on the outer perimeter

- Smaller droplets formed inside the cone

Spiral Hollow Cone

- Larger coarse droplets are formed on the outer perimeter.

Examples of Why You Would Choose This Spray Pattern Over Others

If you are looking for gas cooling or want the liquid to react with a process for smaller droplet size, the spiral full cone nozzle gives you outstanding results.

If wind resistance and heat removal are a concern, the larger droplets produced by the spiral will give you outstanding results.

Nozzle Spray Videos

Full Cone Spiral Spray Nozzle: BETE TF 10 FCN

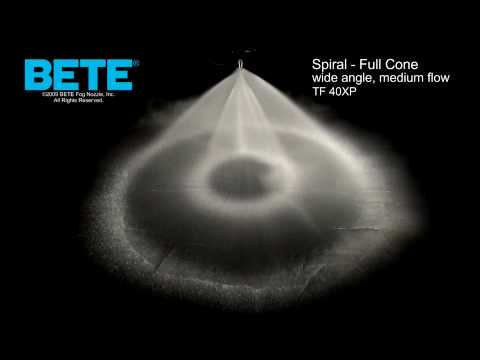

Full Cone Spiral Spray Nozzle: BETE TF 40XP

Full Cone Spiral Spray Nozzles: BETE TF 112-150