DESIGN FEATURES

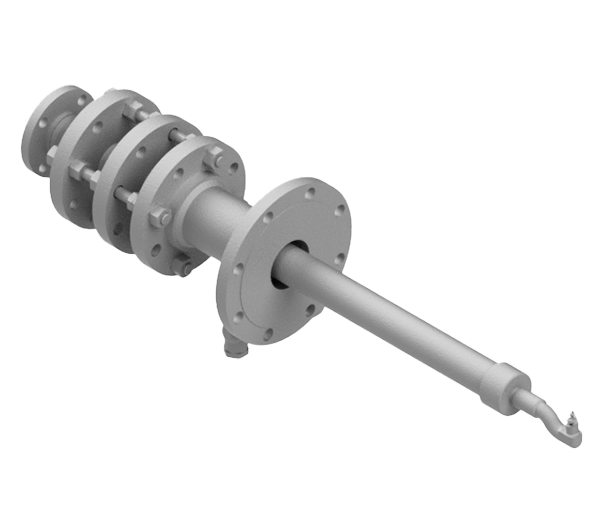

Designed for use with abrasive materials such as limestone slurry

Commonly used for wet FGD (flue gas desulphurization)

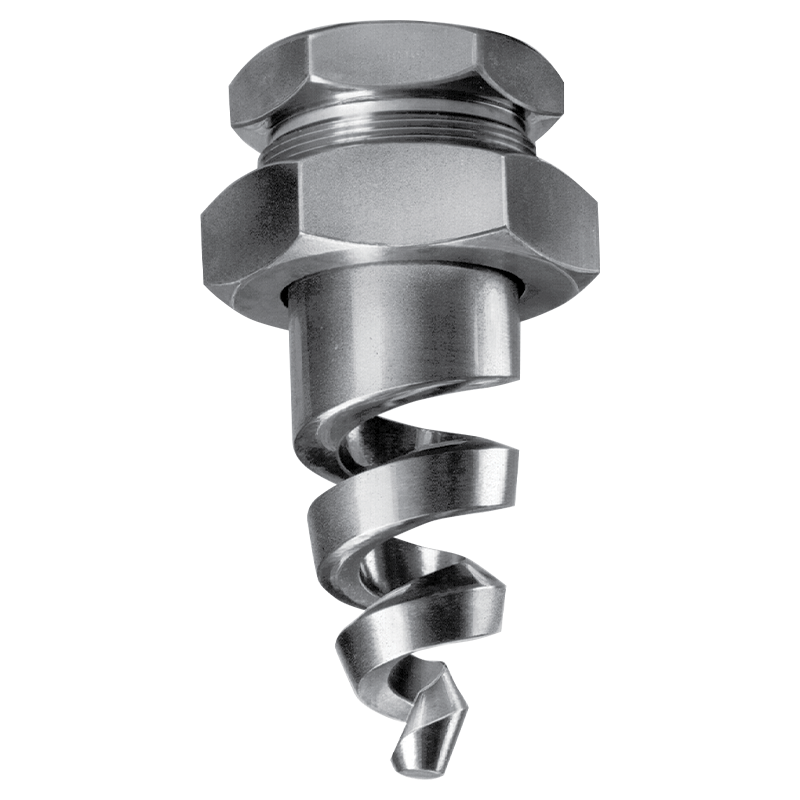

Inherently clog-resistant with no internal parts

Cobalt alloy 6 or RBSC ceramic parts in high-wear areas

High energy efficiency

Flanged and special connections available as required

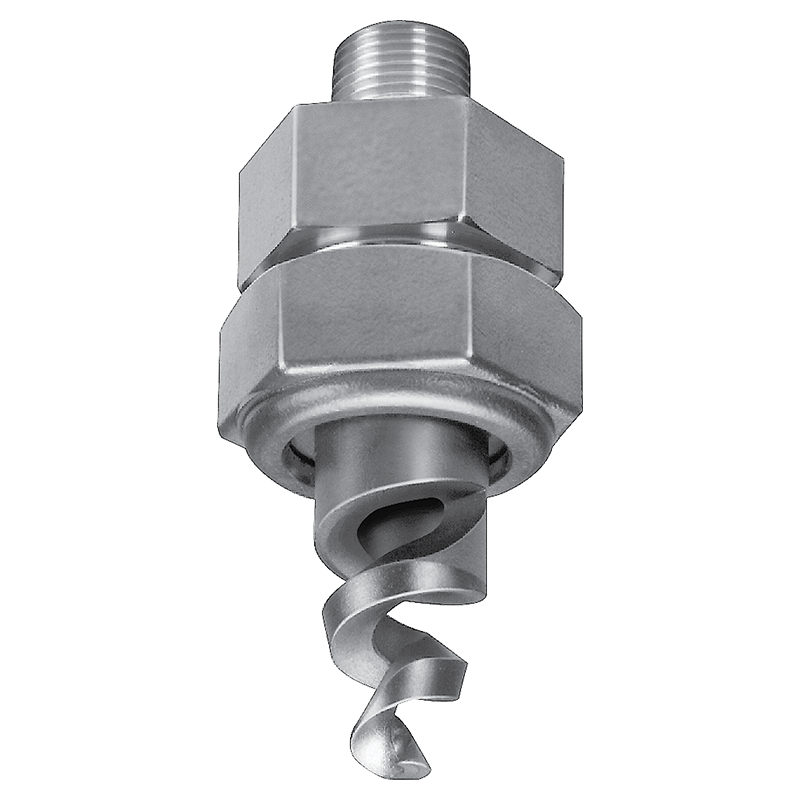

HOW SPRAY PATTERN IS ACHIEVED

The spray pattern of the spiral nozzle is formed by the fluid shearing along with the turns of the spiral, which produce multiple concentric cones. These cones form 2 to 3 bands of relatively coarse droplets surrounded by wider bands of relatively fine droplets.

Available Spray Angles

90 - 120°

Flow Rate Range

0.494 to 3710 gpm

Available Connection Types

- Pipe: 1/4, 3/8, 3/4, 1, 1 1/2, 2, 2 1/2, 3, 4

- Connection Methods: Thread (NPT, BSP, NPSM, BSPP, Male, Female)

Materials

316 / Cobalt Alloy 6, 316 / RBSC

Flow Rates, Spray Angles, Connections

Full Cone

Select a nozzle number below for performance graph, drawings, and to request a quote.

Flow rate (gpm/lpm) is calculated at differential pressure (psi/bar).

Nozzle Number

Connection Sizes

Spray Angles

Flow Rate (gpm) @ Differential Pressure (psi) (Density: 1 SG)

5 psi

20 psi

40 psi

60 psi

100 psi

400 psi

0.494

0.988

1.40

1.71

2.21

4.42

0.919

1.84

2.60

3.18

4.11

8.22

1.41

2.83

4.00

4.90

6.32

12.6

2.12

4.24

6.00

7.35

9.49

19.0

2.86

5.72

8.10

9.91

12.8

25.6

3.76

7.51

10.6

13.0

16.8

33.6

5.84

11.7

16.5

20.2

26.1

52.2

8.52

17.0

24.1

29.5

38.1

76.2

11.7

23.3

33.0

40.4

52.2

104

14.8

29.7

42.0

51.4

66.4

133

23.7

47.4

67.0

82.1

106

212

33.5

67.1

94.9

116

150

300

45.6

91.2

129

158

204

408

59.7

119

169

207

267

534

68.0

136

192

235

304

608

99.1

198

280

343

443

886

125

250

354

433

559

1120

181

362

512

627

810

1620

239

479

677

829

1070

2140

371

742

1050

1290

1660

3320