Automatic spray nozzles offer several advantages, including precise uniform spray coverage, improved product consistency, minimized overspray, and reduced waste. They are essential for many tasks like cleaning, coating, or cooling, where precise intermittent spraying is essential. This article examines the difference between electrically and pneumatically actuated automatic spray nozzles, exploring their unique features and applications.

How Do Electrically Actuated Spray Nozzles Work

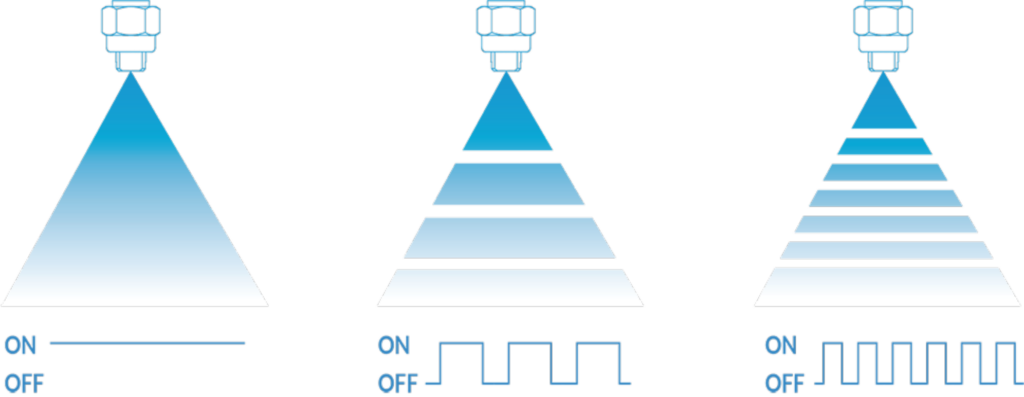

Electrically actuated automatic spray nozzles, also known as hydraulic atomizing nozzles, utilize liquid pressure for atomization without needing compressed air. These nozzles are incredibly fast, with the spray appearing continuous even though it is interrupted 150 times per second. The spray flow rate can be electronically controlled by pulsing the spray while adjusting the cycle’s On-time vs. Off-time ratio using Pulse Width Modulation. Pulsing at high frequency allows the average flow rate to be adjusted while maintaining constant fluid supply pressure and the appearance of continuous, uniform coverage.

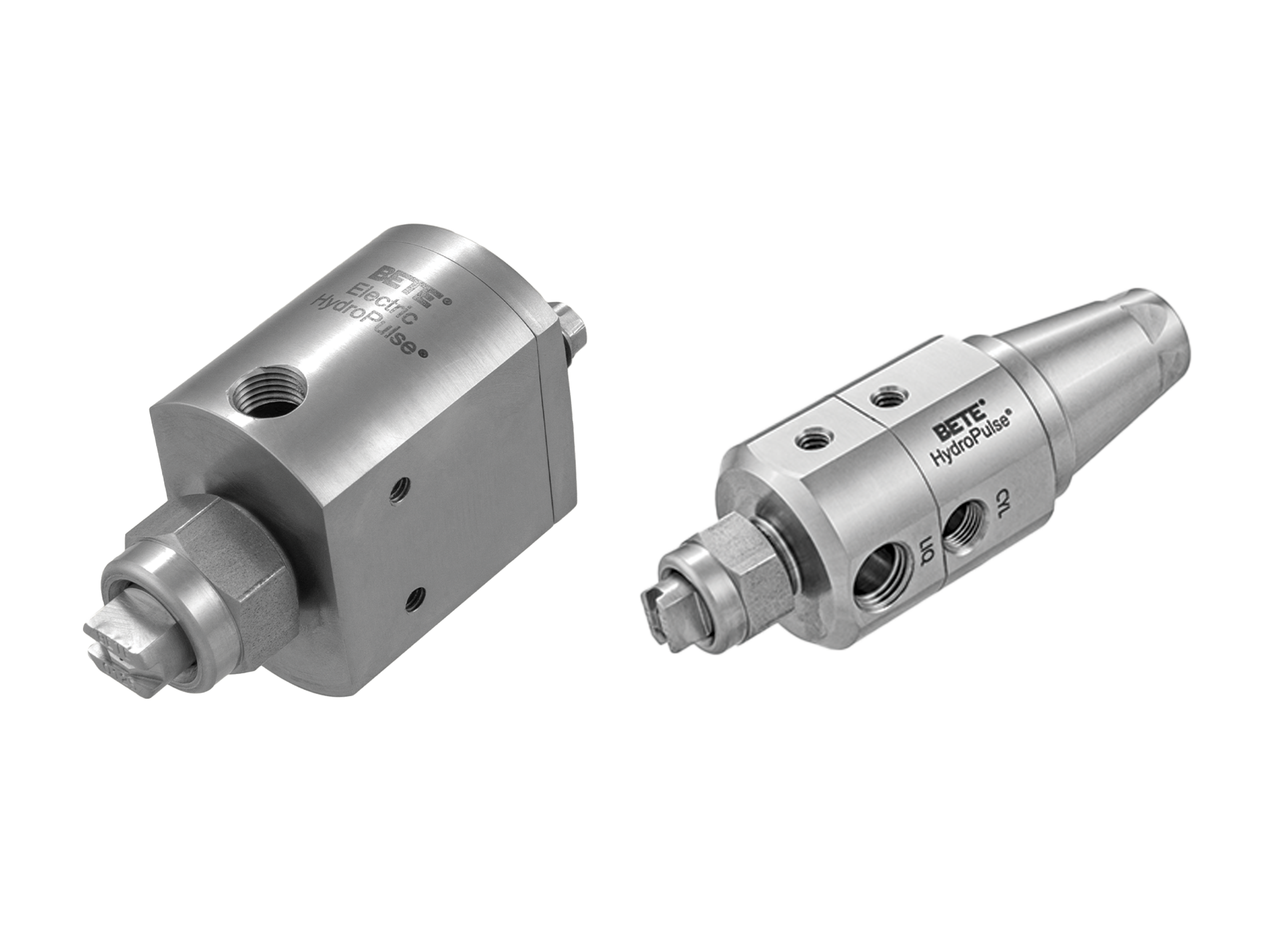

BETE offers the HydroPulse® EHP and EHPI as examples of electrically actuated nozzles. The HydroPulse EHPI is ideal for industrial use, spraying wax or resin onto engineered wood products or aromatics on paper products. For hygienic applications, the EHP is designed for food-grade applications, including spraying additives, flavorings, and antimicrobials onto food products and releasing agents on pans and molds.

You can minimize overspray and improve product quality by utilizing the advanced intermittent spraying features with EHP and EHPI.

How Do Pneumatically Actuated Spray Nozzles Work

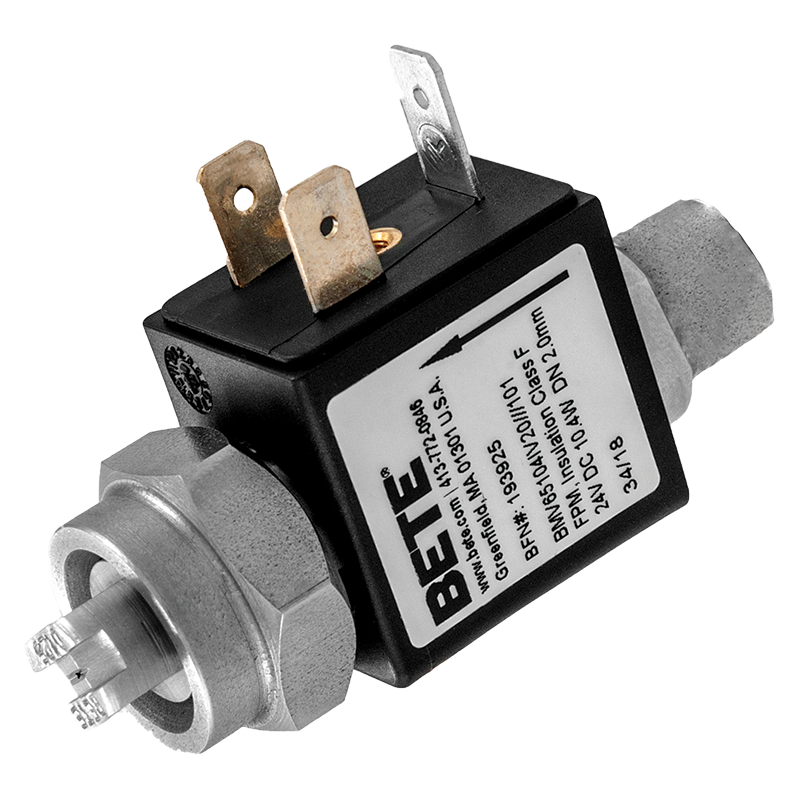

Unlike their electric counterpart, pneumatically actuated automatic spray nozzles require a compressed air source for actuation. These nozzles have a slower actuation time and cannot operate as quickly as electrically actuated nozzles.

BETE’s HydroPulse® PHP is an example of a pneumatically actuated nozzle suitable for precise intermittent spraying in various industrial and hygienic applications. PHP is specifically engineered for spraying thick, dense materials like glues, resins, slurries, and waxes. Unlike the EHP, It can withstand temperatures up to 400°F, which is essential for reducing the viscosity of these materials.

Learn More About Electrically and Pneumatically Actuated Automatic Spray Nozzles and How To Choose the Right One

If you’re looking for precise uniform coverage, electrically or pneumatically actuated automatic spray nozzles are the best intermittent spraying solution. These nozzles offer a wide range of flow rates and spray patterns, with interchangeable tips that save resources and enhance product quality. Please contact our Systems and Fabrications department for expert assistance in selecting the optimal automatic nozzle for your intermittent spray application.