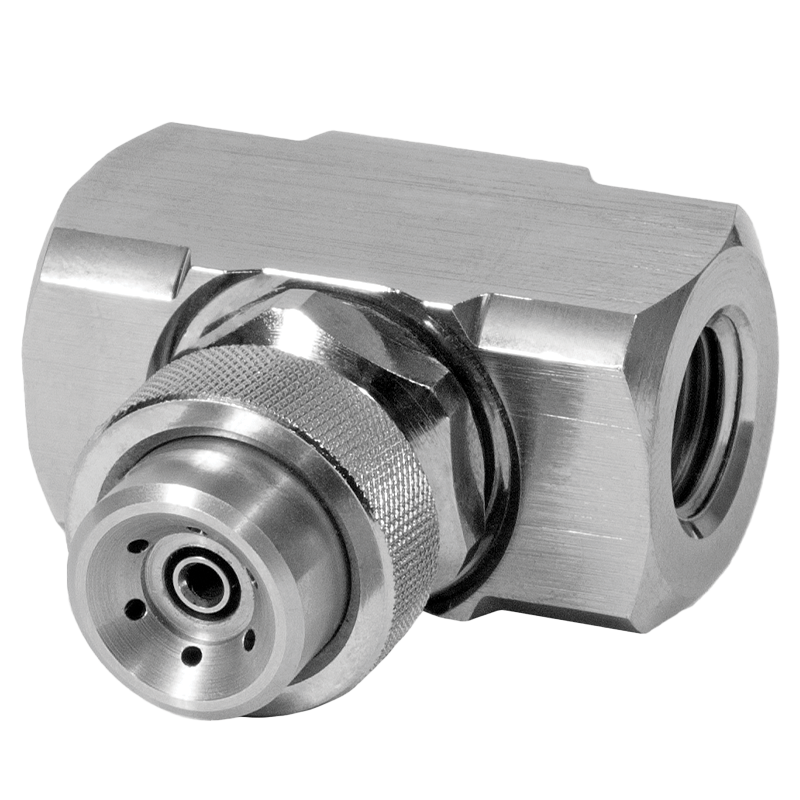

BETE XA Air Atomizing Nozzles

Air atomizing nozzles use the energy in compressed air to produce highly atomized sprays at low flow rates. These nozzles are commonly used for gas cooling, humidification, lubricating, misting, and moistening in various industries, including pollution control, food processing, and refining.

BETE’s XA air atomizing nozzles comprise many interchangeable components that can be assembled to achieve various objectives, including the spray pattern type, body style, and automatic shut-off.

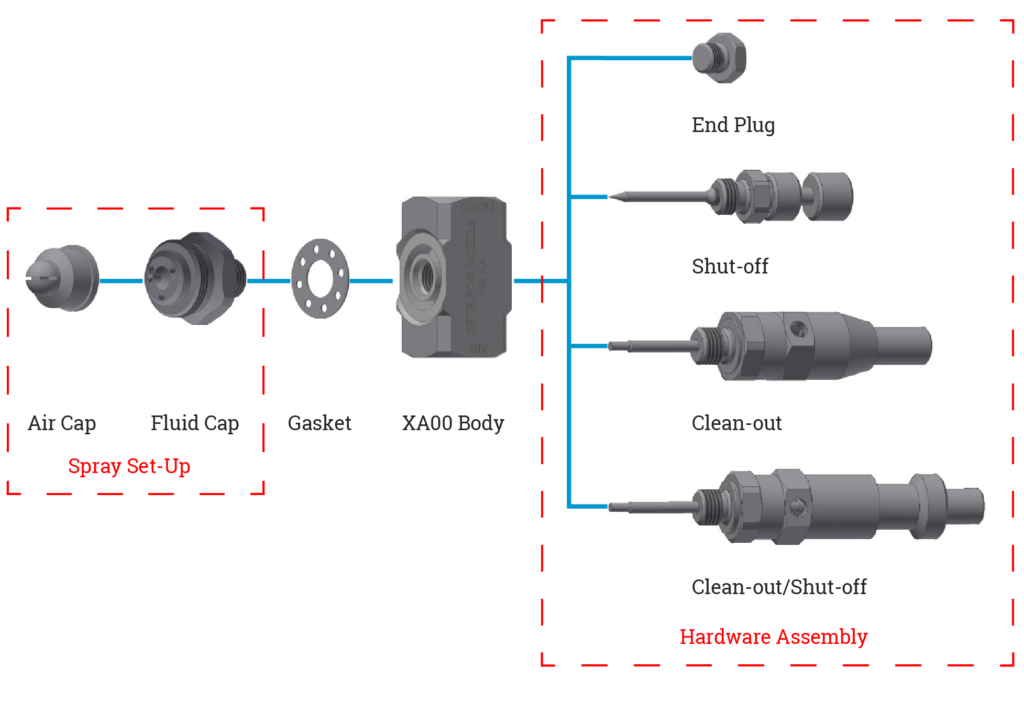

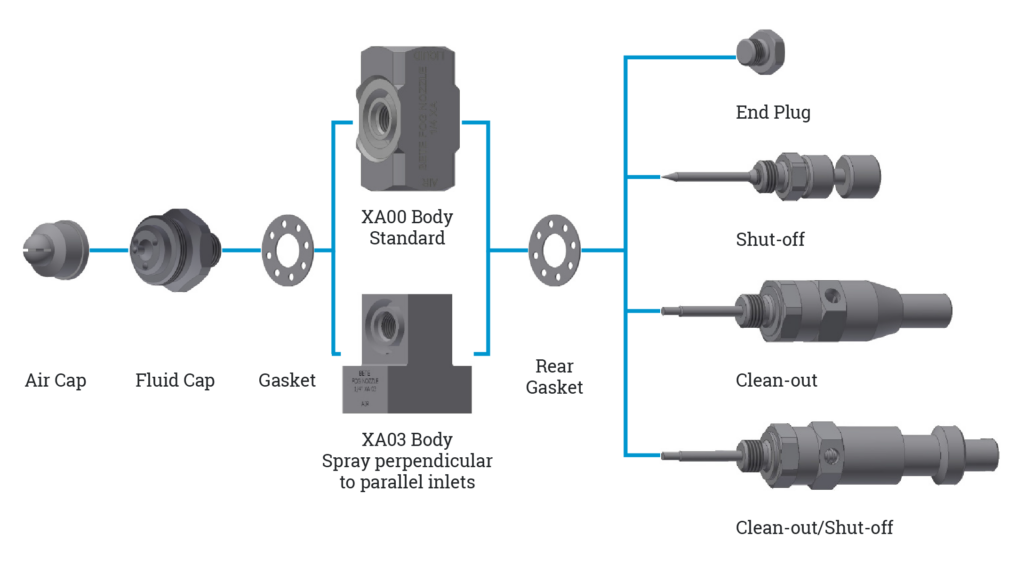

What Are the Basic XA Components & Spray Set-up?

The basic XA atomizing spray nozzle assembly consists of a body, a spray set-up, and a hardware assembly that can provide shut-off and clean-out capabilities.

The spray type and flow rate are determined by the ”set-up”—a specific combination of one air cap and one fluid cap. XA nozzles produce eight different sprays, depending on which interchangeable air cap is selected. Each full cone, hollow cone, or fan spray pattern has multiple different flow rate range options for various applications.

How Does the Basic XA Operate?

The body style and type of hardware assembly will determine if the operation is manual or automatic and if the spray is continuous or intermittent. The automatic operation of the XA has a shut-off plug at the orifice that you can activate with an external control system to prevent excess drip for more critical operations.

For applications requiring continuous spray, the XA00 and XA03 body styles can be combined with an End Plug, Shut-off, Clean-Out, or Clean-out/Shut-off assembly. These same body styles combined with an air-operated shut-off or air-operated clean-out/shut-off provide automatic operation with intermittent spray. These air cylinders provide virtually instantaneous liquid shut-off at rates of up to 180 cycles per minute.

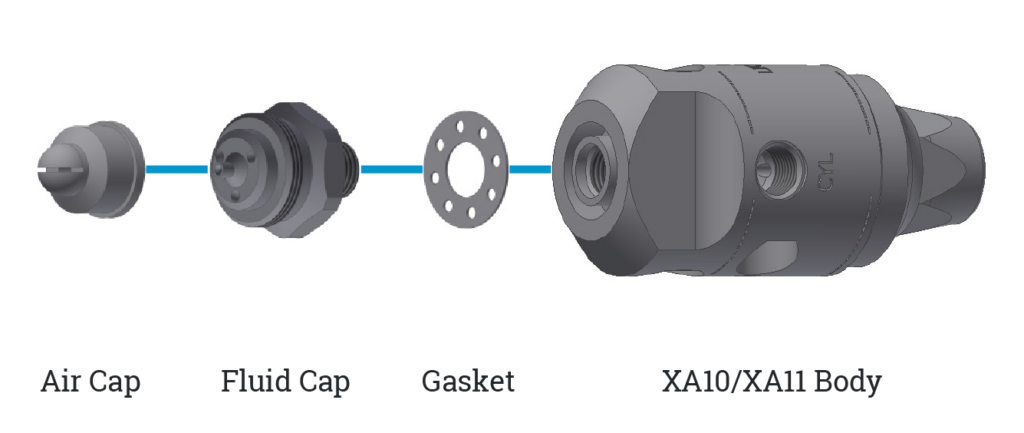

The XA10 and XA11 body styles are recommended when space is confined because they have a built-in air-operated cylinder, and the integral cylinder provides a smaller profile. These air atomizing nozzles are the perfect solution for precise intermittent spray.

Learn More About Additional Components and How to Choose the Right XA Nozzle

The XA air atomizing spray nozzle components are highly versatile, providing customers a wide range of options to meet their specific application needs. In addition to the XA assemblies, BETE offers additional components such as solenoid valves, filters, regulators, strainers, and spray extensions to create a comprehensive spray system. The selection of each component’s size and type depends on the application’s unique requirements.

If you need help choosing the right XA nozzle and components for your application, please contact our Applications Engineering Department for assistance. With over 70 years of experience in the spray nozzle industry, we know how to optimize your process with high-performance air atomizing nozzles that perfectly fit your applications.