LOW FLOW, MISTING, AND AIR ATOMIZING NOZZLES

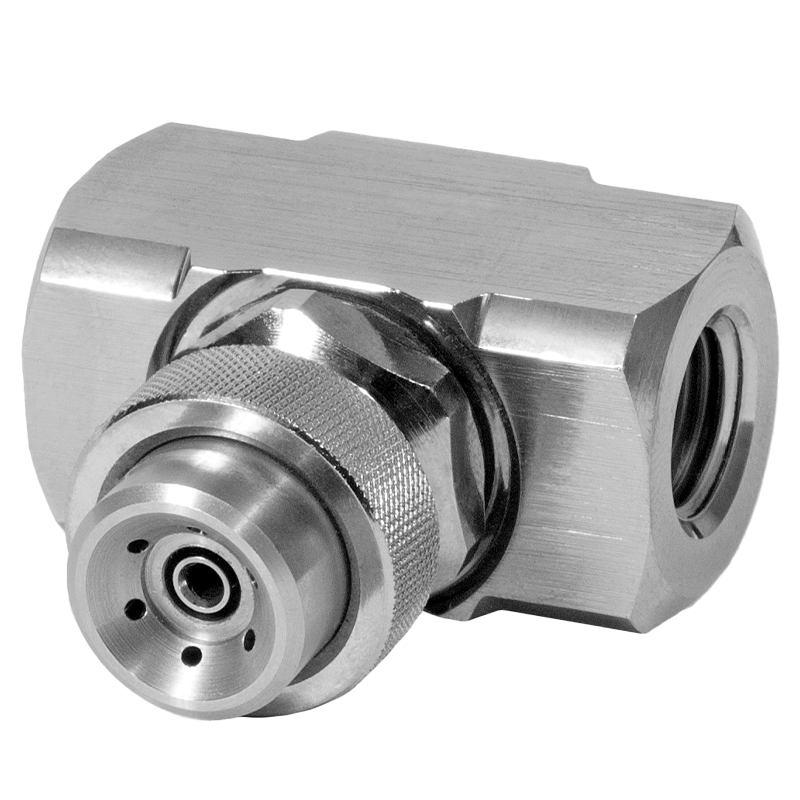

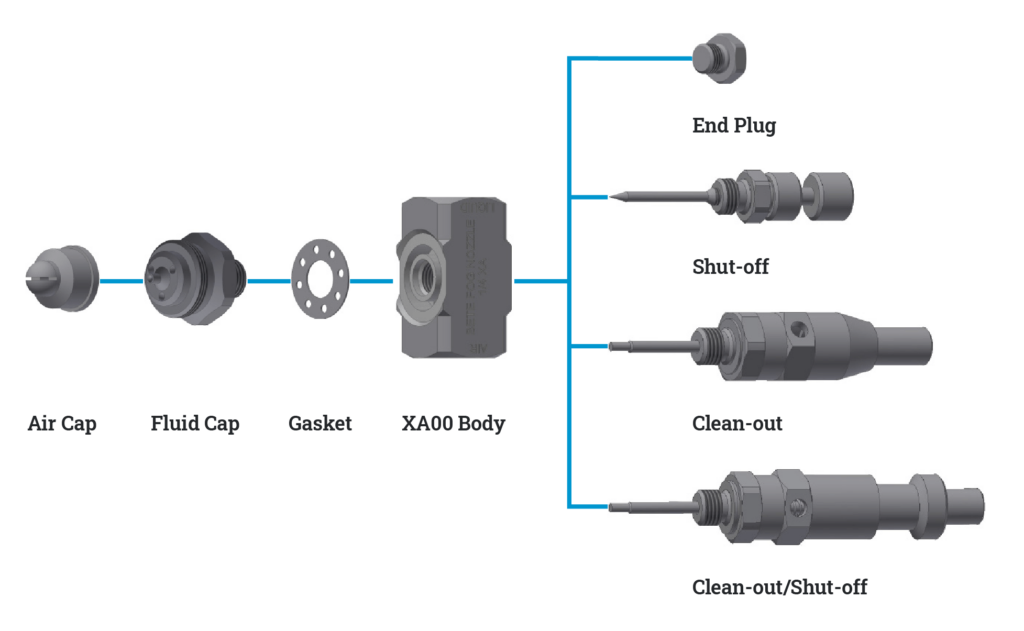

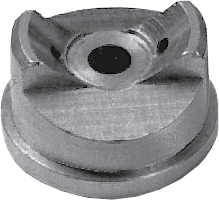

XA00 Body with End Plug

XA00 Body with Clean-out Hardware

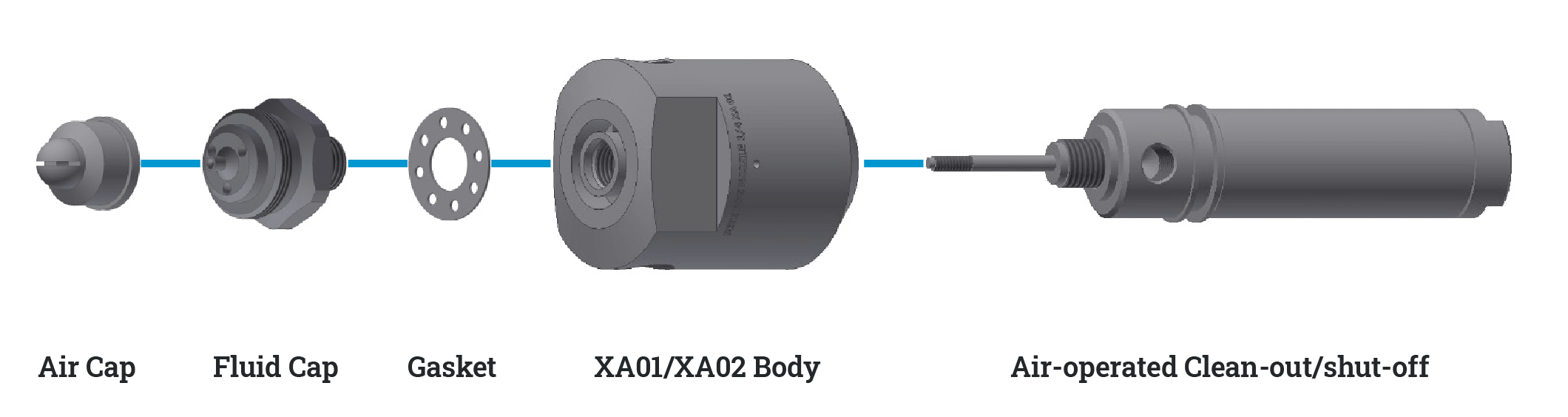

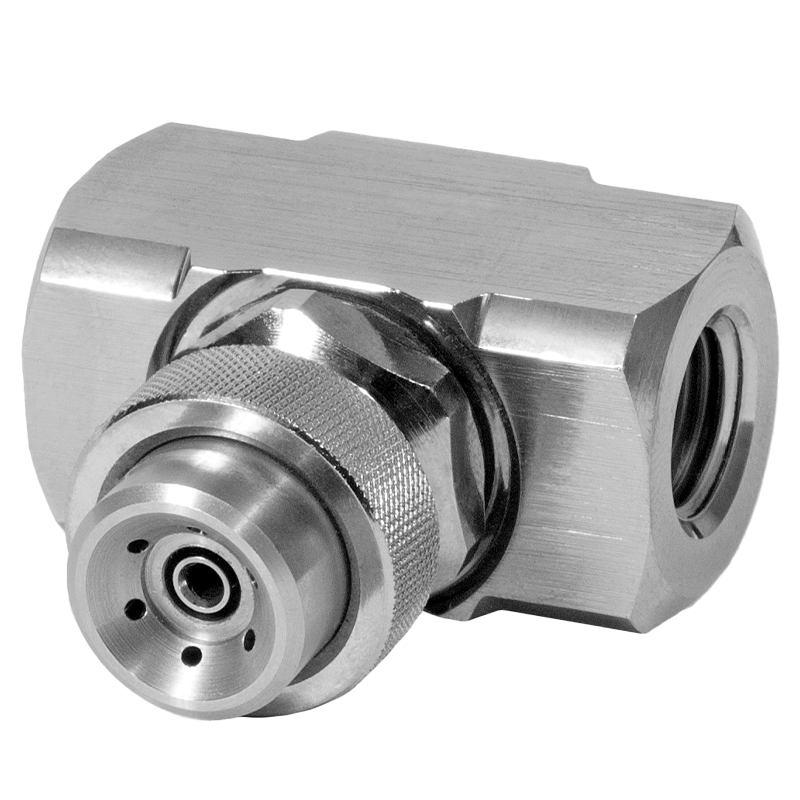

XA02 Body with Air-operated/Shut-off

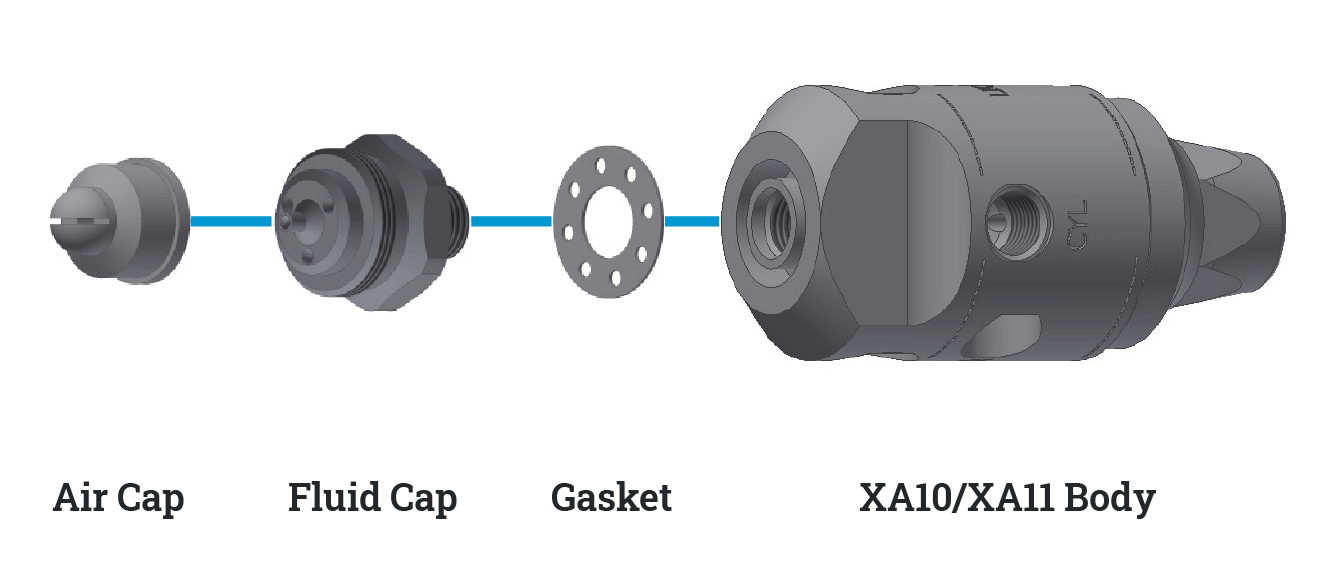

XA10 Body

XA nozzles produce eight distinctly different types of sprays, depending on which interchangeable air and fluid caps are selected. The set-up determines the spray type and flow rate with a specific combination of one air cap and one fluid cap.

Types of Spray Set-Ups

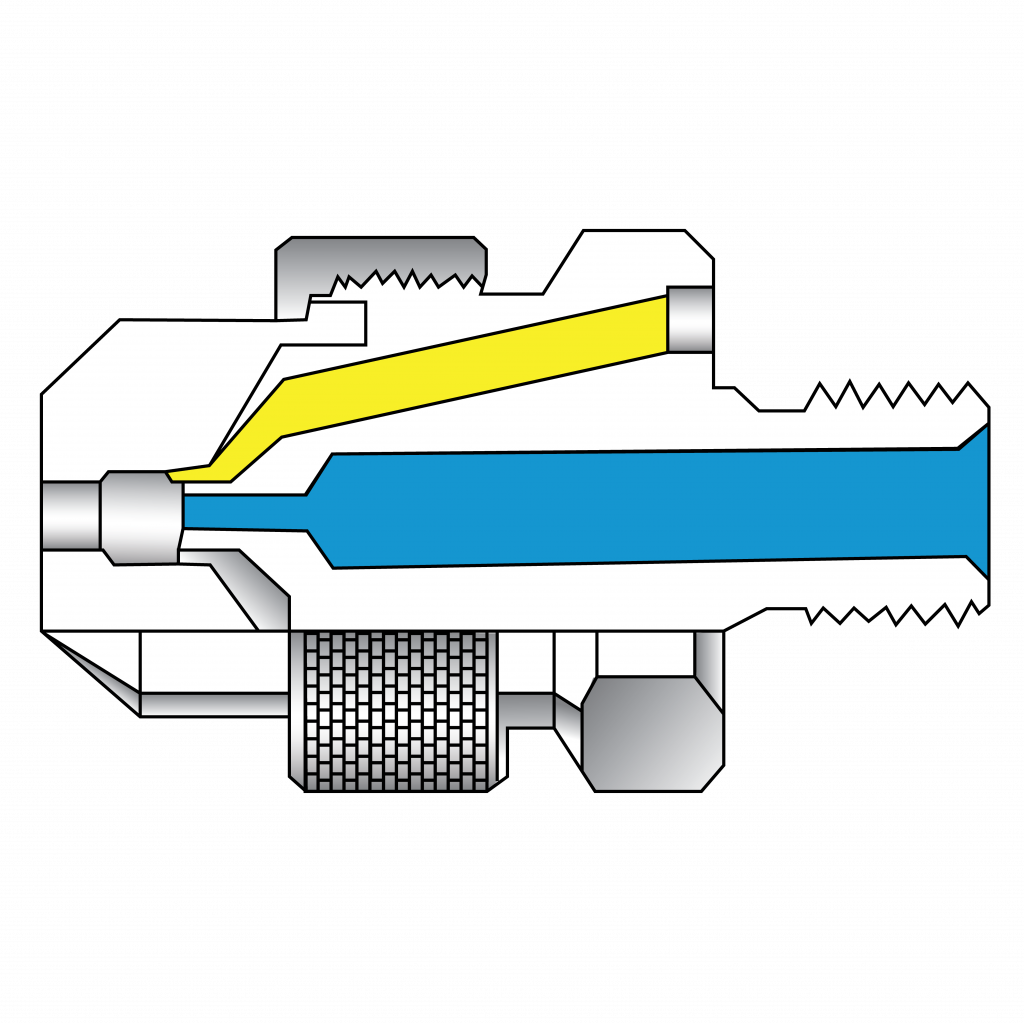

Internal Mixing

- Liquid and air streams come together inside the nozzle and are mixed, and they exit through the same orifice.

- The streams are not independent; airflow changes will affect the liquid flow.

- Not suitable for viscous liquids above 200 cP.

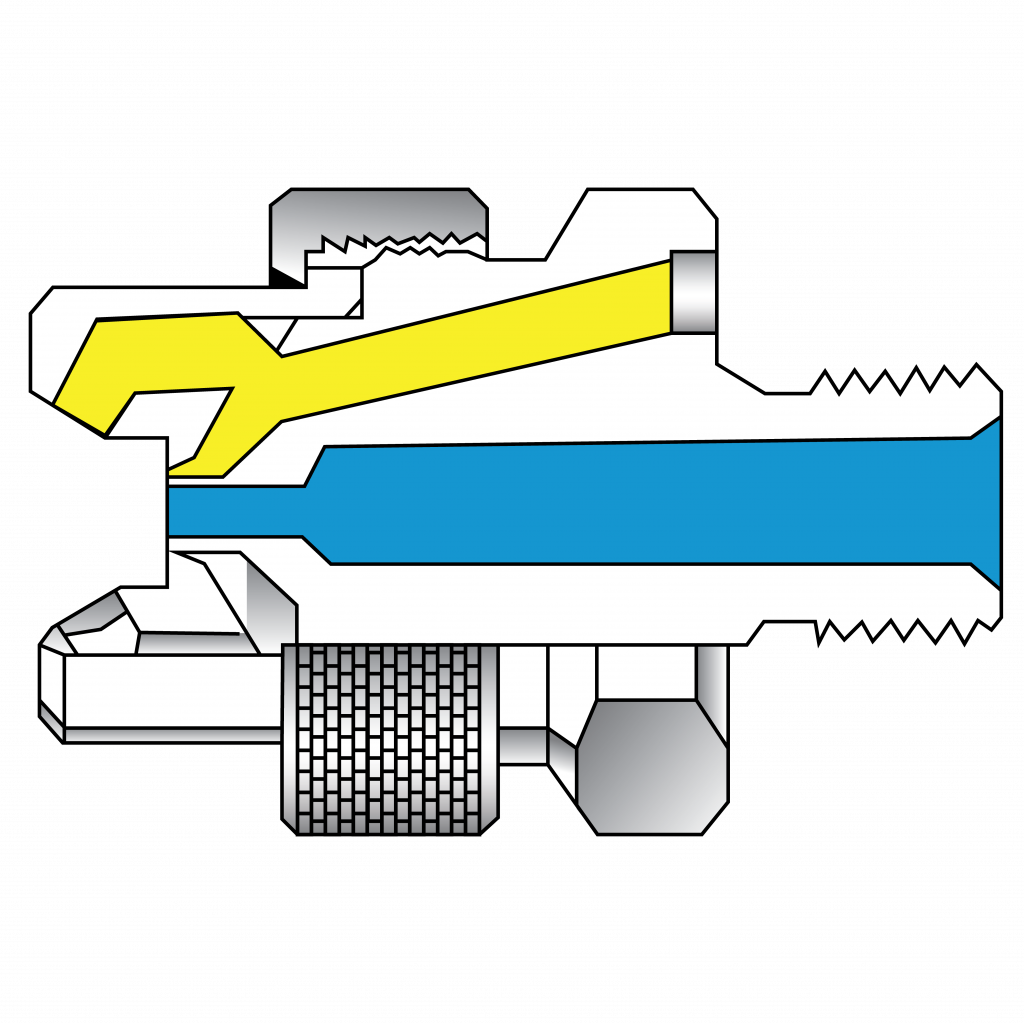

External Mixing

- The air and liquid streams exit the nozzle independently through each orifice.

- Air and liquid flow rates can be independently controlled, allowing precise fluid metering.

- Suitable for all liquids, including viscous liquids above 200 cP.

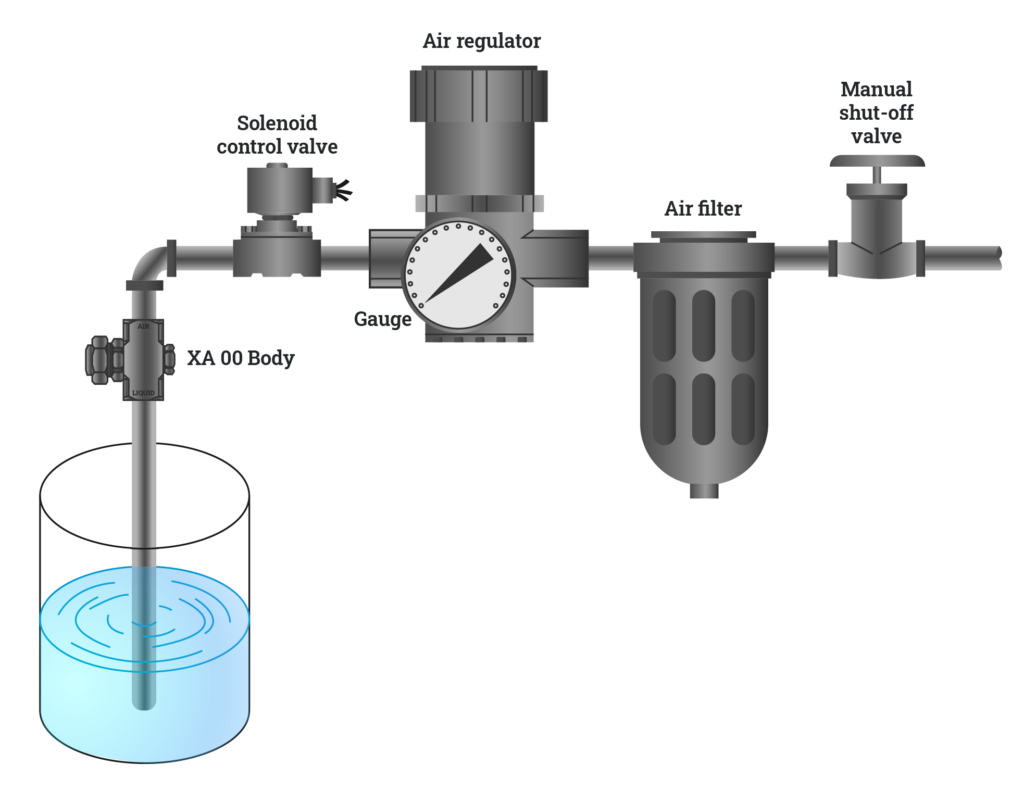

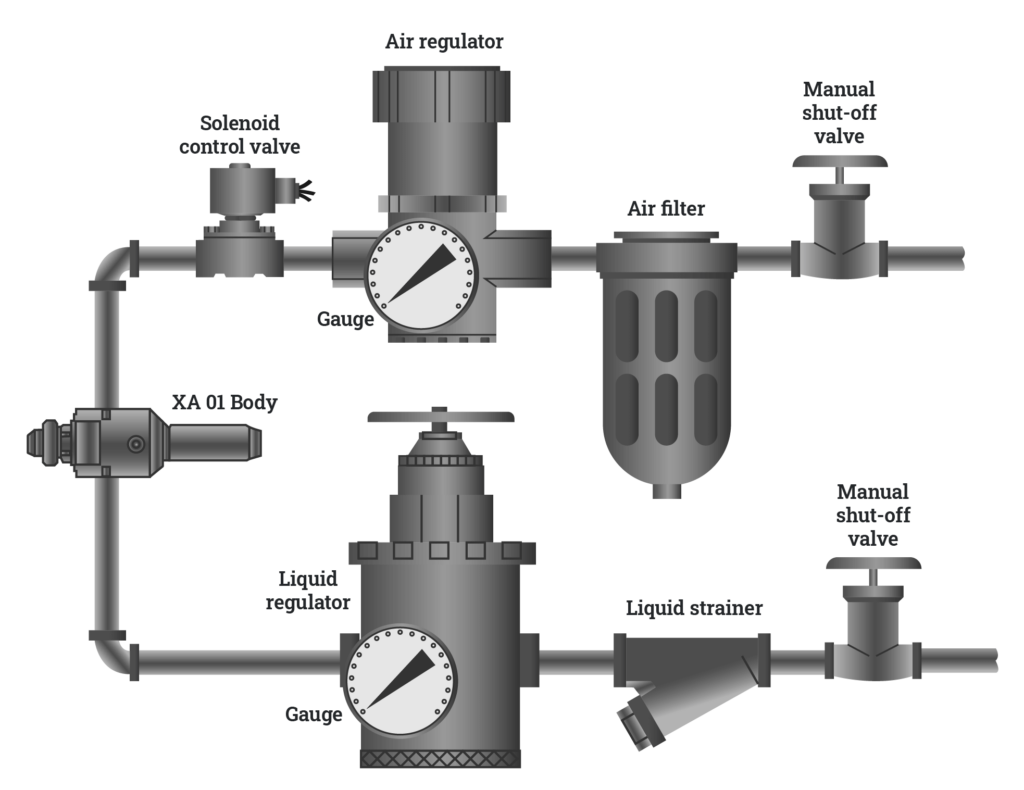

Internal and External Mix Set-ups require the liquid supplied to the nozzle under pressure from a municipal water supply, pump, or pressure vessel. Siphon Set-ups use the flow of compressed air within the nozzle to siphon liquid from a container. Siphon set-ups are frequently used for spraying additives from a container without a pump. They provide the lowest flow rates available in the XA series (as low as 0.1 GPH).

Basic XA Operation & Components

The basic XA spray nozzle assembly consists of a body, a spray set-up, and a hardware assembly that can provide shut-off and clean-out capabilities.

NON-AUTOMATIC

The basic XA body requires hardware assembly for manual shut-off or clean-out/shut-off.

Recommended Body Styles: XA00, XA03, XA05

Recommended Hardware Assemblies: End Plug, Shut-off, Clean-Out, or Clean-out/Shut-off

AUTOMATIC

The round XA body can be equipped with an air cylinder to provide shut-off or clean-out/shut-off for automatic operation.

Recommended Body Styles: XA00, XA01, XA02, XA10, XA11

Recommended Hardware Assemblies: Air-operated Shut-off, or Air-operated Clean-Out/Shut-off

Spray Nozzle Assembly & Set-Up Numbers

Standard XA assemblies include an air cap, fluid cap, and body style and hardware assemblies and mounting hardware is optional. The chart below can be used as a guide for creating an XA spray assembly set-up number. For Set-Up Numbers please refer to the section “Air Cap & Fluid Cap Spray Set-Up Numbers.

*For extensions, end plug hardware is standard; air-operated hardware may be provided on an application-specific basis.

Set-Up Number

and 1/2"

AD Air Cap

EF Air Cap

SR Air Cap

XW Air Cap

PF Air Cap

FF Air Cap

ER Air Cap

PR Air Cap

Fluid Cap

Related Resources

XA Component Options – Metric

XA Complete

XA Complete – Metric

XA Component Options

XA Accessories

XA Troubleshooting

XA FAQ

Recommended Products

XAAD Internal-mix wide angle round

XAEF External-mix flat fan

XAER External-mix narrow round

XAFF INTERNAL MIX DEFLECTED Flat FAN

XAPF INTERNAL MIX FLAT FAN

XAPR INTERNAL MIX NARROW ANGLE

XASF SIPHON-FED FLAT FAN

XASR SIPHON-FED ROUND

XAXW INTERNAL-MIX EXTRA-WIDE ANGLE

XA10 and XA11

SPRAY LANCE, INJECTOR, & QUILL SOLUTIONS