Overview

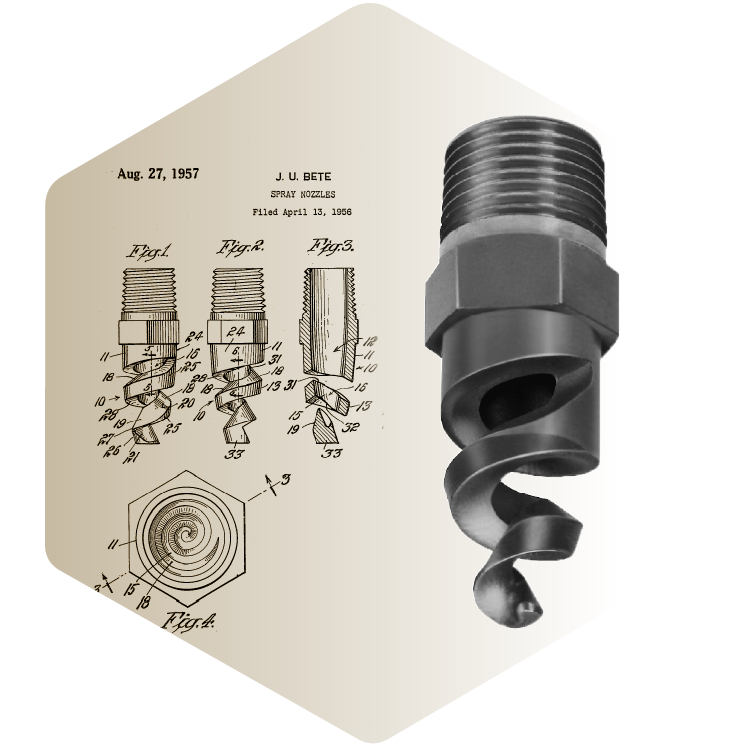

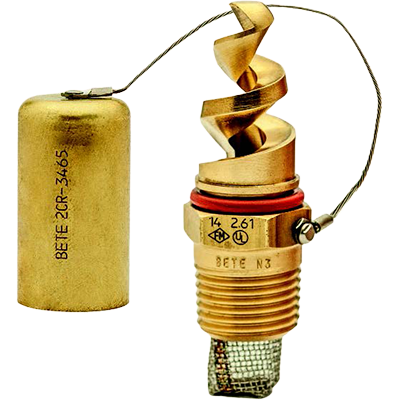

The BETE Spiral Nozzle — often recognized by its distinctive corkscrew shape — represents a cornerstone of spray nozzle engineering. Invented by John Bete in 1948, the spiral became the foundation of BETE, being our original “Fog Nozzle,” and delivering a level of atomization that sets a new benchmark for spray performance. Sometimes referred to informally as a “helix,” “corkscrew,” or “pigtail” nozzle, its iconic design continues to play a vital role across a wide range of industrial spray applications, including fire protection, gas scrubbing, and evaporative cooling.

The earliest rendition of the spiral, known as the “B” series, featured an internal spreader pin designed to distribute the liquid evenly over its five spiral turns. This version was primarily used for fire protection in the oil and gas industry, but its effectiveness soon attracted attention in other sectors. As the design further developed, BETE gained insight into its versatility, and new sizes and variations emerged, resulting in many new nozzle series for a broader range of applications. Although the original design has since retired, its key feature — superior atomization — remains at the heart of the numerous spiral series today.

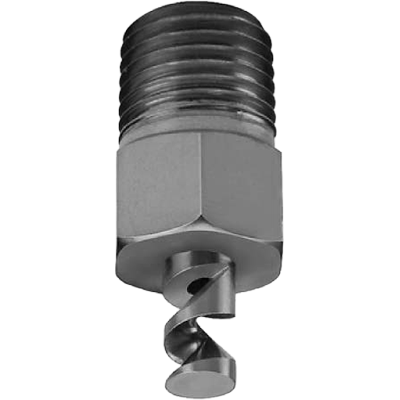

Design Features & Advantages of the Spiral

Fine Atomization: The spiral produces the smallest droplet sizes compared to whirl nozzles of the same flow rate and pressure drop.

Clog-Resistant Performance: Its durable, one-piece construction with no internal parts minimizes plugging, making it ideal for applications where reliability is critical.

Efficient Operation: Operating at lower pressures with high-discharge velocities, the spiral design allows for smaller piping sizes and reduces system costs. A spiral will deliver 1 ½ to 2 times the flow of other cone nozzles of the same pipe size.

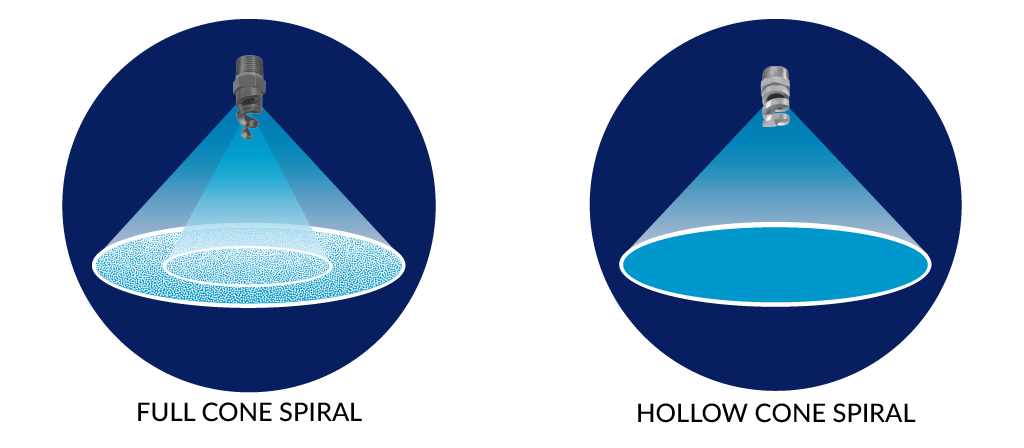

Spiral Spray Pattern: The spiral creates its spray pattern through a unique shearing process as liquid flows across the spiral turns. A hollow cone pattern forms when most of the droplets project outward, creating a ring-shaped spray with minimal coverage in the center. In contrast, the full cone spiral pattern is formed by a series of concentric hollow cones, producing two to three bands of medium-sized droplets surrounded by wider bands of relatively finer droplets, delivering more complete coverage.

• TF Full Cone Nozzle: TF nozzles, BETE’s most popular spirals, deliver reliable, high-efficiency coverage for applications such as gas scrubbing, gas cooling, and chemical injection. TFs are available in a wide range of connection sizes, spray angles, and materials — many stocked for quick delivery.

• TF Hollow Cone Nozzle: This spiral produces a ring-shaped spray pattern with most of the droplets on the outer perimeter, making it ideal for applications like gas quenching, evaporative disposal, and dust suppression.

• TFXP Series: The TFXP is an elongated version of the TF full cone spiral, engineered with a larger free passage to handle fluids with larger particulates and to minimize plugging. It delivers the same excellent atomization with even higher reliability for the harshest environments.

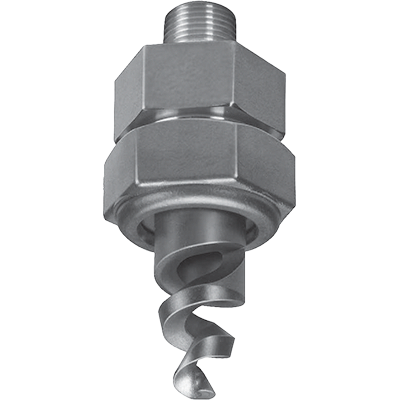

• ST Series: The ST nozzle, a rugged, abrasion-resistant variant of the TF, features two- or three-piece construction for easy maintenance. Being designed for harsh environments, it offers extended service life with replaceable tips made from Cobalt Alloy 6 or reaction-bonded silicon carbide (RBSC).

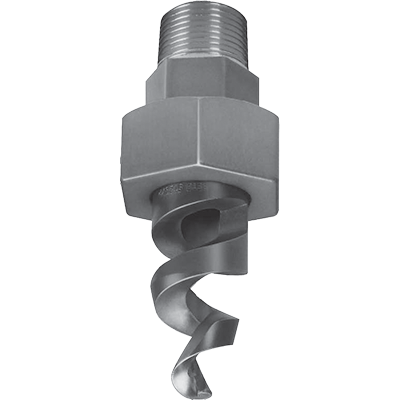

• STXP Series: The STXP combines the abrasion-resistance and two- or three-piece design of the ST with the clog-resistant elongated design of the TFXP. It features a larger free passage, making it ideal for extremely harsh environments where reliability is crucial.

• N Fire Protection Nozzle: Specifically engineered for fire protection systems, the N series spiral holds third-party certifications including Underwriters Laboratories (UL), Factory Mutual (FM), and the US Coast Guard. Its robust, clog-resistant design makes it the trusted choice for critical fire suppression applications.

• L Series: L nozzles, the smallest spirals in the lineup, are made for fine misting applications such as cooling, humidification, and dust control. Along with its compact size, it delivers consistent atomization with a highly efficient spray.

• Tank Washing (TW) Nozzle: This stationary tank cleaning spiral nozzle, available with 180° and 270° options, has a unique, clog-resistant design with a narrow profile that fits through small openings.

Conclusion

Since its introduction in 1948, the spiral nozzle has established itself as a dependable solution for a wide range of spray applications. Its simple, robust design and ability to deliver fine atomization with minimal clogging has made it a practical choice across industries where reliability and performance matter.

Wondering if a spiral nozzle will help improve your process? Contact BETE Applications Engineers today.