DESIGN FEATURES

Designed specifically with critical fire and explosion suppression applications in mind

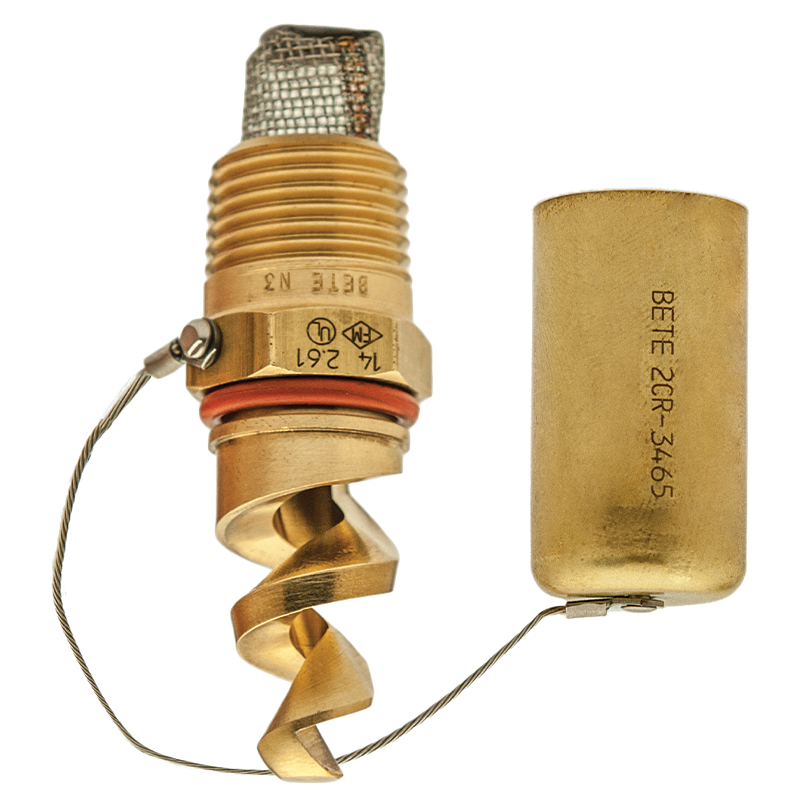

One-piece, no internal parts

Clog-resistant

Rugged, compact design

Optional protective cover

All N1-N3W nozzles provided with integral strainer

N1-N3W strainer: 316 SS, 24 mesh (0.027" opening)

Factory Mutual (FM) and U.S. Coast Guard approved models; UL listed

HOW SPRAY PATTERN IS ACHIEVED

The spray pattern of the spiral nozzle is formed by the fluid shearing along with the turns of the spiral, which produce multiple concentric cones. These cones form 2 to 3 bands of relatively coarse droplets, surrounded by wider bands of relatively fine droplets.

The large surface area of spray improves evaporation and cooling.

Available Spray Angles

90 - 120°

Flow Rate Range

3 to 597 gpm

Available Connection Types

- Pipe: 1/2, 1, 1 1/2

- Connection Methods: Thread (NPT, BSP, Male)

Materials

Brass, 316, Nickel Aluminum Bronze, Titanium

Flow Rates, Spray Angles, Connections

Full Cone

Select a nozzle number below for performance graph, drawings, and to request a quote.

Flow rate (gpm/lpm) is calculated at differential pressure (psi/bar).

Nozzle Number

Connection Sizes

Spray Angles

Flow Rate (gpm) @ Differential Pressure (psi) (Density: 1 SG)

10 psi

20 psi

50 psi

75 psi

100 psi

150 psi

3.00

4.24

6.71

8.22

9.49

11.6

5.31

7.51

11.9

14.5

16.8

20.6

8.25

11.7

18.5

22.6

26.1

32.0

12.0

17.0

26.9

33.0

38.1

46.7

16.5

23.3

36.9

45.2

52.2

63.9

21.0

29.7

47.0

57.5

66.4

81.3

33.5

47.4

75.0

91.8

106

130

47.4

67.1

106

130

150

184

64.5

91.2

144

177

204

250

84.4

119

189

231

267

327