SIMPLIFY SANITATION. SAVE TIME. CUT COSTS.

BETE works closely with customers on specialized applications to deliver effective, cost-saving spray solutions. In the food processing industry, we’ve listened carefully to understand the importance and challenges of sanitation — whether cleaning processing areas, conveyor belts, or other equipment.

The Problem

Too often, sanitizing methods don’t target the specific application. This results in long cleaning cycles, excessive water usage, and costly production downtime.

The Solution

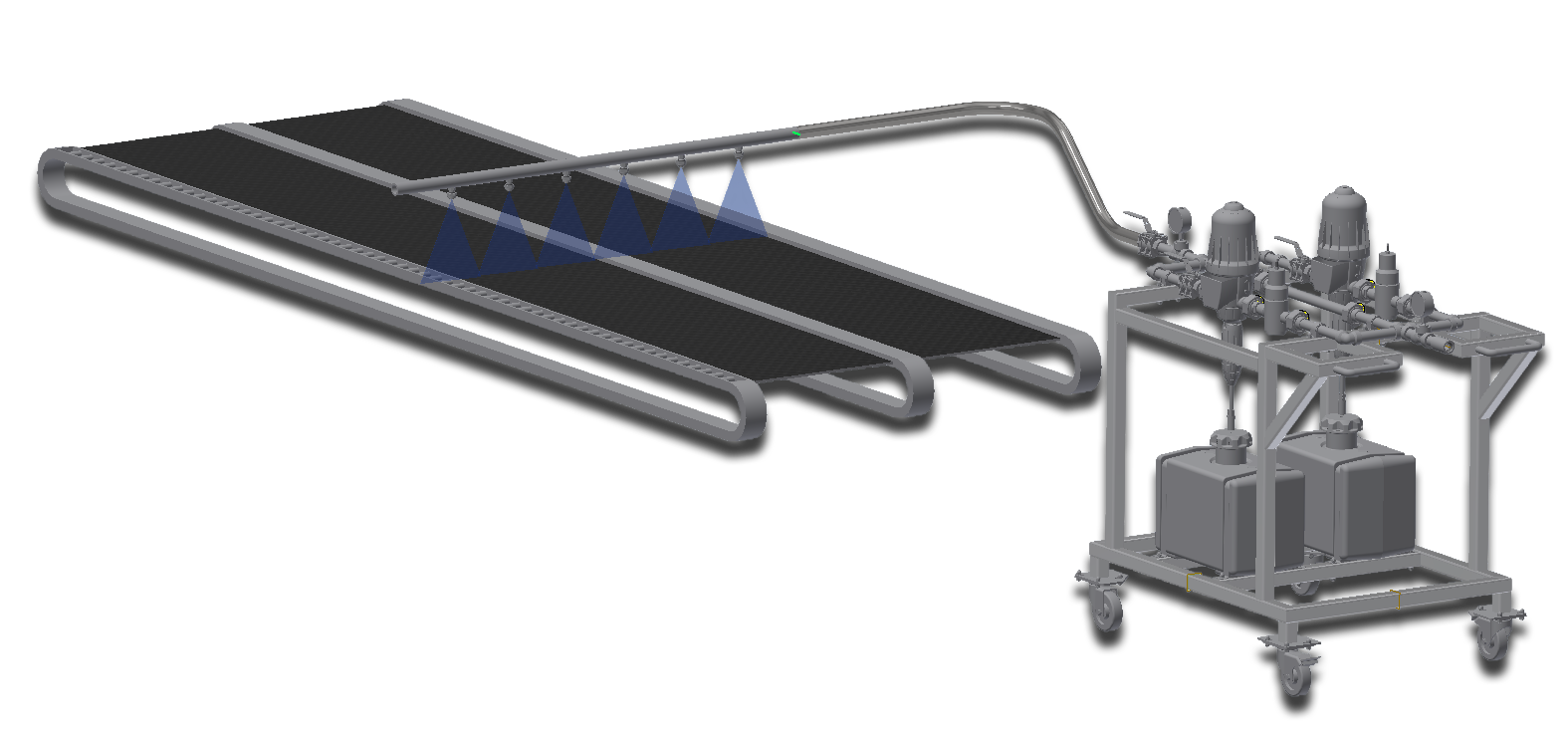

BETE’s FlexiSan Modular Spraying System — designed for versatility, the spray system optimizes Open Plant Cleaning (OPC) and delivers effective, consistent cleaning for a range of applications, from everyday washdowns to tackling tough soils. Use our FlexiSan spraying systems to apply cleaning and sanitizing agents to a wide range of equipment, including conveyors, hoppers, bins, and mixers, as well as other critical process areas.

THE FLEXISAN ADVANTAGE

Streamlined Sanitation – Easily switch between rinse, clean, and sanitize steps for faster, more efficient washdowns

Portable & Easy to Use – A rugged, stainless steel cart moves effortlessly between cleaning zones

Tough on Soils – Handles everything from light residues to heavy build-up like syrups and coatings

Saves Water & Chemicals – Precision spraying minimizes waste while maximizing effectiveness

Built for You – Flexible options and automation features to fit your exact process needs

FLEXISAN BASE SYSTEM

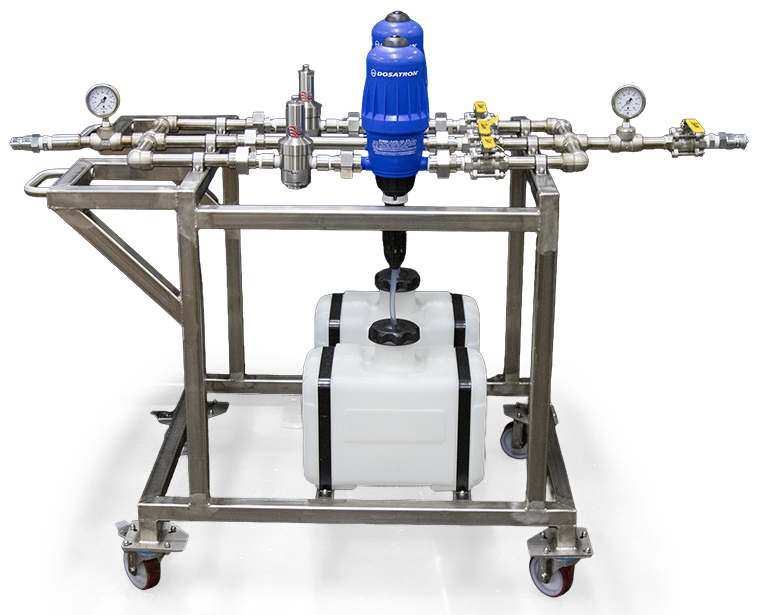

The base spray system includes a durable, mobile cart with integrated chemical handling and at least one Clean-in-Place (CIP) spray header assembly. Engineered for simplicity and mobility, the cart connects directly to plant water and can deliver up to two chemicals — typically a cleaner and a sanitizer — through the spray header(s). Its portable design makes it easy for operators to move between cleaning zones and quickly connect to supply drops or CIP headers.

For light soils, standard plant water pressure (60-200 psi / 4.1-13.8 bar) is sufficient to loosen and dislodge contaminants. With dual holding tanks for cleaner and sanitizer, the cart makes it easy to switch seamlessly between rinsing, cleaning, and sanitizing — streamlining the entire sanitation process.

KEY SYSTEM COMPONENTS

FLEXISAN MAX SPRAYING SYSTEM

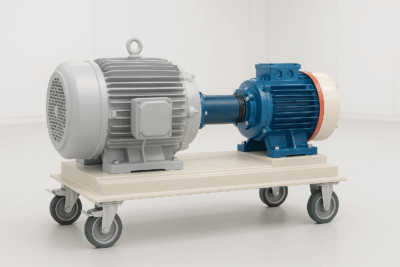

For heavier soil levels that require hot water and higher pressure for fast, effective cleaning, such as chocolate coatings or heavy syrups, use our FlexiSan Max. Built upon the same components as our base FlexiSan system, the FlexiSan Max adds a pump package with quick mechanical and plumbing connections to the base cart unit, integrating it with the supply and delivery lines.

Delivering between 400 and 600 psi (27.6-41.4 bar) to the CIP spray bar, this additional pump system provides the impact needed to effectively and efficiently remove tough soils. The result is significantly shorter cleaning cycles — for conveyors, this can mean only a single rotation is required.

KEY FEATURES AND SPECIFICATIONS OF THE PUMP PACKAGE

Looking for further system customization?

Inquire with one of our Spray Experts if you would like any of the following:

-

Controls and control integration

- Automated valves

- Spray bar purge (compressed air)

- Single button cleaning operation with adjustable timers

- Fully integrated/automated, stationary, Clean-in-Place (CIP) systems

- FlexiSan cart add-on: handheld washdown wand with FDA-compliant hose connection

Related Spray Technology Solutions

Read Our Case Studies

BETE’s FlexiSan Modular Spray System Cuts Conveyor Cleaning Time & Saves Bakery Over a Half a Million Dollars a Year

FlexFlow® Spray System Ensures Precise Application of Ingredients for Cracker Manufacturer