Why Use Tank Cleaning Nozzles?

Tank cleaning nozzles are used to clean tanks and other vessels of various shapes and sizes. They feature a spray head that delivers a powerful, focused spray of liquid to remove dirt, scale, and other contaminants quickly and efficiently without using other tools. These nozzles can be used with various cleaning agents, including hot and cold water, detergents, acids, and alkalis.

Manual tank cleaning requires various tools, such as brushes, scrapers, and pressure washers. The downsides of manual cleaning include poor soil removal, use of harsh chemicals, and placing workers at risk of injury. Automated cleaning processes are more efficient and cost-effective because they are safe and require less time and resources.

How To Select A Tank Cleaning Nozzle

Tank cleaning nozzles are categorized into three operating principles: stationary, reactionary force, and rotary jet. The type of nozzle selected will depend on the soil type, tank size, and operating principle.

Soils are classified into three categories ranging from light, moderate, and heavy.

Light soil: A soil that is considered a liquid residue or light powder not anchored to the surface and can be easily rinsed away.

Moderate soil: Soils anchored to the surface require repetitive spray impact, temperature, and chemicals for removal.

Heavy soil: Soil is heavily caked onto the surface, requiring a nozzle with a longer dwell time to aid in cleaning.

For light to moderate soils, stationary or reactionary force operating principles work best. These nozzles clean tanks ranging in size from 3ft to 25ft in diameter.

Stationary nozzles, also called static, have no moving parts and can withstand higher temperatures. Innovative designs like the BETE HydroClaw® and TW spiral nozzle provide sizeable free passage superior to static spray balls. When particulates and filtration are problematic, we recommend stationary nozzles because they are clog-resistant.

Reactionary force or free-spinning nozzles are fluid-driven and use the spray media’s reaction force to drive the spray head’s rotation. Compact nozzle designs like the HydroWhirl® Mini and HydroWhirl® Stinger provide complete 360° spray coverage and superior cleaning performance through impact and repetition. These nozzles are made from FDA-compliant 316L SS material for food-grade applications.

Rotary jet or controlled rotation nozzles are best for heavy soils because they provide a longer dwell time on the surface for effective soil removal. The spray media flows through internal gears on the body, which rotates sets of high-impact jet nozzles through an efficient 2-axis orbital spray pattern. Tank cleaning machines like the HydroWhirl Orbitor are designed for the most challenging cleaning applications in food, beverage, and chemical processing. Rotary jet tank cleaning machines consume 50% less water than static spray balls and clean up to 40% faster, using less energy and fewer resources. They can clean tanks, tanker trucks, and railcars up to 65 ft in diameter.

Other Factors That Influence Tank Cleaning

Soil type and tank size are important considerations for selecting a nozzle, but other factors can influence how effectively a tank is cleaned. Tank size, pump capacity, and nozzle arrangement are as important as the tank cleaning nozzle used.

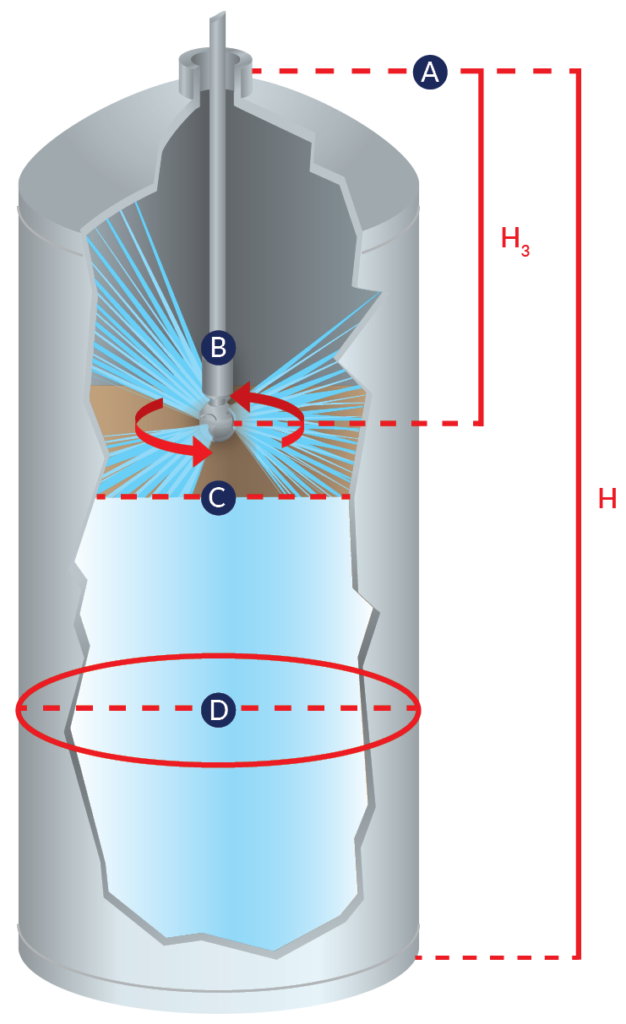

A. Nozzle Placement – The nozzles should be positioned in the upper part of the tank when possible. However, nozzles placed too close to the tank ceiling will deflect off the tank ceiling, losing the cleaning impact.

B. Pump Capacity – The pipe size depends on the required flow rate and should be selected to ensure the pressure losses in the pipe system are as low as possible. The required static operating pressure must be directly available at the nozzle and match the pump power. Too much pressure loss in the pipe system may cause poor nozzle performance.

C. Fill Line – When permanently mounting nozzles inside the tank, position them above the fill line. The nozzle is prevented from coming in contact with the product, where bacteria buildup and cross-contamination can result. After the cleaning cycle, remove the nozzle because bacteria can adhere to the crevices.

D. Tank Diameter Size – Tanks come in various sizes and shapes. Selecting a suitable tank cleaning device depends on the soil type and the vessel’s diameter. BETE offers tank cleaning nozzles designed to clean tanks up to 65+ ft in diameter.

Drain Hole Size – Drain hole size ensures the drain can handle whatever fluid volume enters the tank. If the drain hole size is too small, water can accumulate in the tank, causing interference with the cleaning process. In some cases, a recirculating pump may be advantageous if draining is problematic.

Spray Shadows – Agitators, baffles, and pipes prevent the spray from reaching the areas behind them, known as spray shadowing. Installing multiple nozzles will provide the necessary coverage to clean these areas. Position the nozzles, so the sprays overlap and ensure proper cleaning.

More Information On BETE Tank Cleaning Nozzles

Whatever your tank cleaning application requirement is, BETE has a cleaning solution for you. BETE uses the latest spray technology for designing tank cleaning nozzles to ensure reliable and effective cleaning solutions that reduce water consumption, save on resources, and lower costs. Contact us for more information.