Why Use Air Atomizing Nozzles?

Air atomizing spray nozzles are commonly used for coating, gas cooling, humidifying, lubricating, moistening, and misting. These nozzles are common in food processing, pollution control, and petrochemical processing.

In this article, we’ll explain what an air atomizing spray nozzle is and what it can be used for.

What Is An Air Atomizing Spray Nozzle?

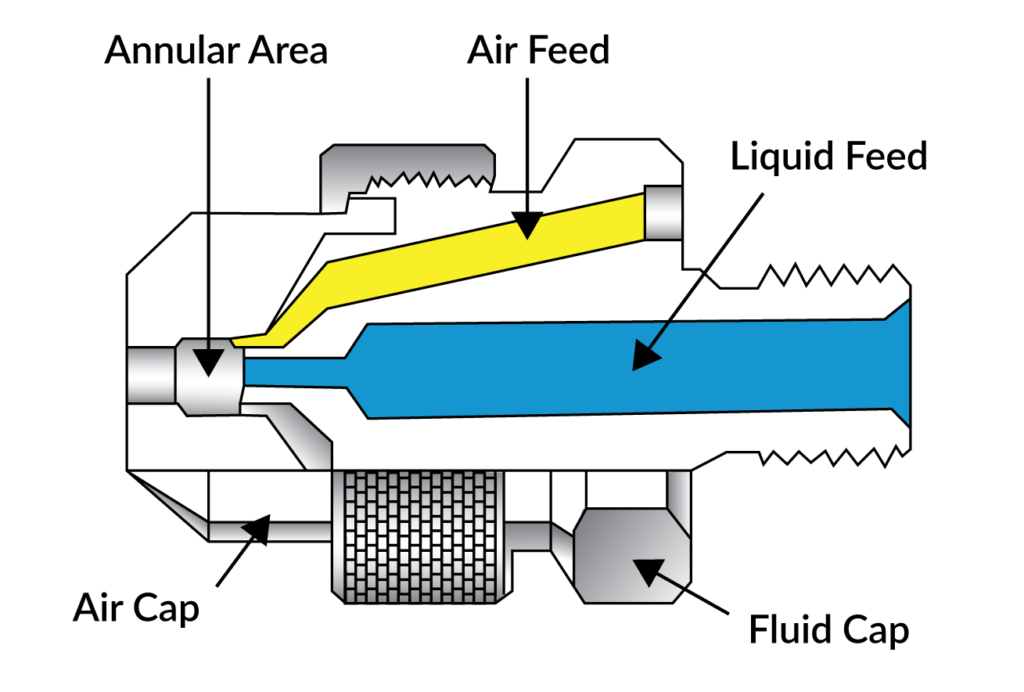

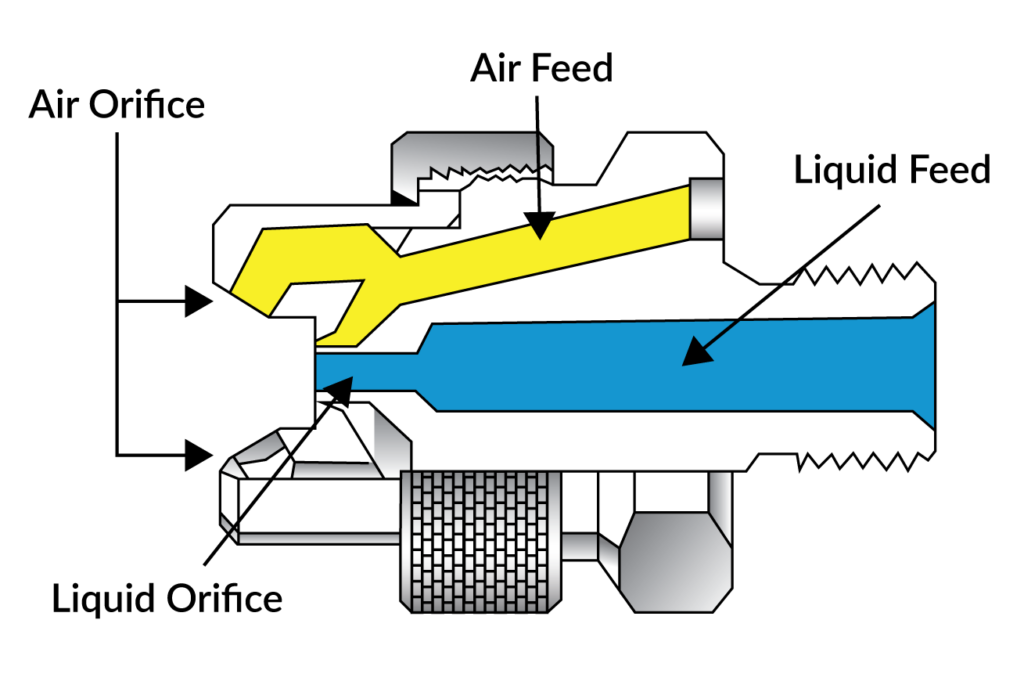

Air atomizing spray nozzles atomize fluids by combining liquid and compressed air/gas at low pressures to form very fine droplets. They can create either fan or full cone spray patterns, and the fluid and air can be mixed internally or externally depending on the nozzle design.

Internal mixing air atomizing nozzles are typically unsuitable for viscous liquids above 200 cP. Liquid and air are mixed inside the nozzle and exit through the same orifice. These streams are not independent, so changes in airflow will affect the liquid flow. This method works best with spraying liquids that have similar properties to water.

External mixing air atomizing nozzles are suitable for liquids greater than 200 cP. Air and liquid streams exit the nozzle independently through each orifice, allowing for precise fluid metering. This method works best for viscous materials, including oils, adhesives, and lubricants.

What Are Air Atomizing Nozzles Used For?

One of the main advantages of air atomizing nozzles is their ability to produce very fine droplets with high accuracy and consistency. This makes them ideal for applications where uniform droplet size and distribution are important, such as gas cooling and scrubbing in pollution control. Unlike single-fluid nozzles, smaller droplets can be achieved with air atomizing nozzles using relatively lower liquid pressures.

Another advantage of these nozzles is their capability to spray viscous liquids using external mixing nozzles. This is ideal for the food industry when coating products with seasonings and flavorings is required or for lubricating trays or molds using oils as release agents. A single fluid nozzle would not spray viscous materials efficiently.

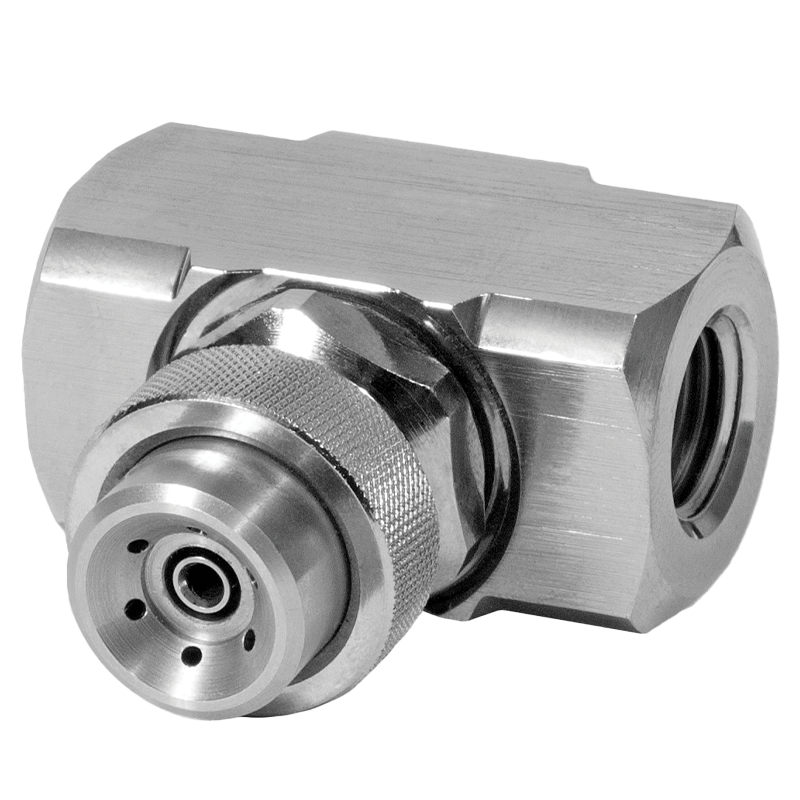

BETE’s XA Nozzle System offers versatility for all air atomizing applications. A total of eight different types of sprays can be produced depending on the air and fluid cap selected. The XA nozzle system has many interchangeable components for achieving various spray objectives.

One drawback of using air atomizing nozzles is the additional cost of using compressed air. These costs can be kept moderately low when the right nozzle is used and performs efficiently, improving the production process. High air consumption can indicate the wrong nozzle is being used for the process and further evaluation should be conducted.

Learn More About Air Atomizing Nozzles And How To Choose The Right One

BETE offers a full line of air atomizing spray nozzles to fit virtually any industrial or commercial application. We can also custom engineer any spray nozzle or complete spray system you may need.