Precision Spray Technology for

the Beverage Industry

Maximize productivity and save resources with BETE’s effective nozzle solutions for beverage processing.Streamline Production With BETE Spray Nozzles and Spraying Systems

We design and engineer precision spray nozzles, headers, manifolds, and complete spray systems to accurately and consistently apply coatings, lubricants, and liquids of various viscosities. From conveyor lubrication and bottle coating to sanitizing and cooling, BETE spray technology helps beverage operations stay efficient, safe, and profitable.

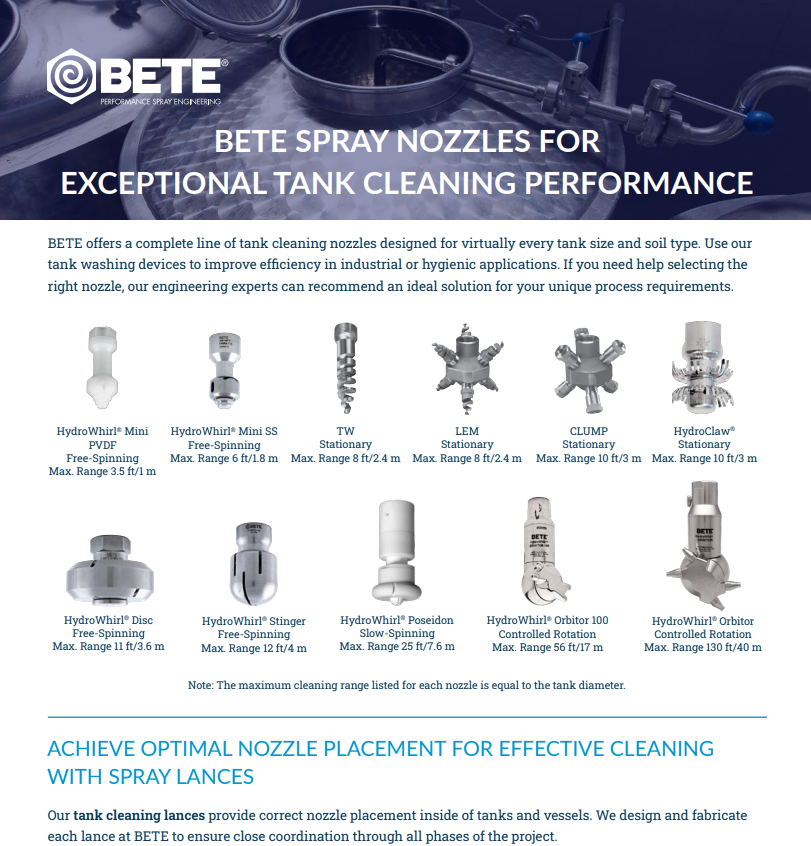

Use our high-performance tank cleaning products to clean and sanitize beverage processing vessels, preventing bacteria and batch contamination. BETE’s rotational tank cleaners deliver up to 360° coverage and significantly reduce water and solvent use—saving time, resources, and money. Whether you’re cleaning small tanks up to 6.5 ft (2 m) in diameter or large horizontal tanks, trucks, or railcars over 65 ft (20 m), BETE offers a wide selection of options in stock and ready to ship.