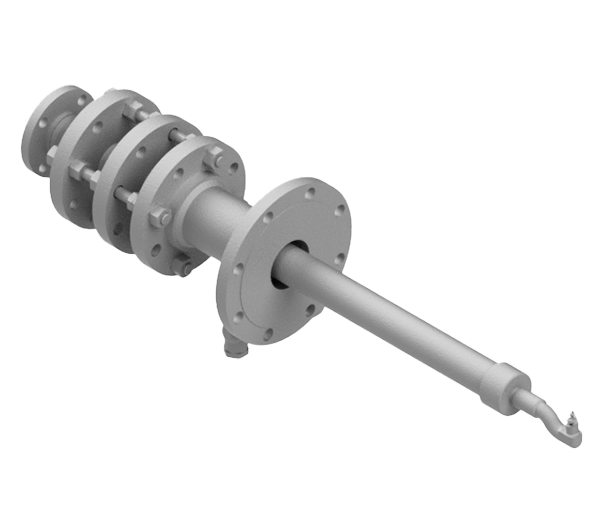

Dry Scrubbing Nozzles, Tangential Whirl, Hollow Cone Spray Nozzles

40 psi - 10 gpm

2.8 bar - 37.9 L/min

A spray pattern that projects a ring of spray with very few droplets inside the ring. Tangential spray inlet simplifies piping by eliminating the need for an elbow. A hollow cone pattern provides immediate contact between the gas and the spray in scrubbing applications.

Design Features

- Conventional design using tangential whirl method of atomization

- Right angle

- Durable

- Use where a circular pattern is required or in the large areas with multiple installations where there is considerable overlapping of sprays

- Male and female connections

- Large free passage

Other materials and custom designs are made possible by BETE's state-of-the-art manufacturing facility in Greenfield, MA. An on-site investment foundry and a full range of CNC machines allow a level of flexibility unmatched in the nozzle industry. The BETE Difference BETE's mission goes beyond just selling spray nozzles: it is to provide engineered spraying solutions that exceed customer expectations in every detail. Extensive in-house capabilities, including CAD design and rapid prototyping, investment casting, welding, and spray testing, make it possible to offer the highest level of quality throughout every phase of production.