Spray nozzles may be a small component of complex processes, but their functionality is critical to success. Nozzle quality ensures that a complete spray system will operate effectively and efficiently. A proper nozzle maintenance program can help identify problem areas and prevent unscheduled production downtime from escalating into higher operation costs and unnecessary waste. In this article, we’ll examine the different types of nozzle damage and offer suggestions for maintaining nozzles to optimize spray performance and wear longer.

Identifying Common Types of Nozzle Damage

Nozzles may sustain various types of damage during use, which affects their performance and efficiency. Regular inspection, proper maintenance, and selection of nozzles made from appropriate materials for specific applications can help mitigate problems and ensure the longevity and efficiency of the nozzles. Here are some common types of nozzle damage.

- Erosion/Wear

- Corrosion

- Operation in High Temperatures

- Caking/Bearding

- Accidental Damage

- Clogging

- Improper Installation

Nozzle Maintenance Tips You Can Benefit From

By identifying the typical causes of spray performance issues, you can troubleshoot whether maintenance or nozzle replacement is necessary to enhance your process. Here are some nozzle maintenance tips to keep your nozzles functioning properly.

Visual Inspection of Nozzle

Visual inspection can reveal signs of damage that may have occurred during installation or normal operation. Although not always obvious, a brief visual inspection can typically detect wear or corrosion.

Visual Inspection of Spray Pattern

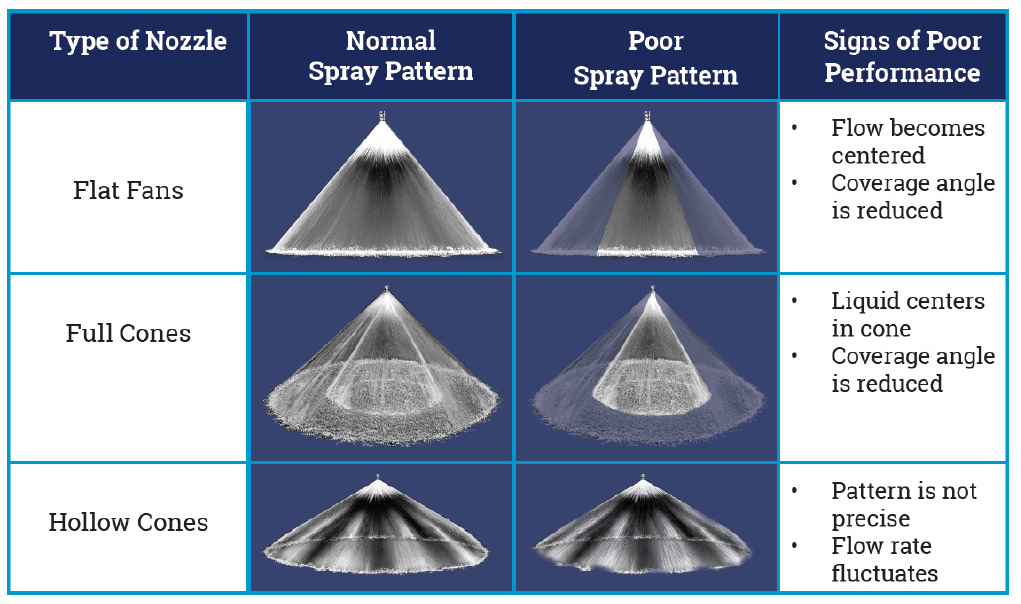

Streakiness, heavier sections, fluttering, or skewed/lopsided spray patterns may indicate that a nozzle is not functioning as designed or intended.

Monitor Flow Rate & Pressure

The flow rate and operating pressure of the nozzle are directly related. If these values change from nominal, it can indicate issues with the nozzle like clogging or excessive wear.

Monitor System Performance & Effectiveness

Changes in overall system performance, such as temperatures, pollutant levels, and coverage, can indicate nozzle issues like damage, clogging, or wear.

Clean Nozzles Properly

The best method to clean nozzles without damaging them is by soaking or washing with appropriate cleaning fluids and using a soft brush or ultrasonic cleaning bath. Never use sharp instruments such as probes or picks.

Add a Line Strainer or Filter

Particulates, dirt, or other minerals are often found in the source of the fluid being supplied, which may clog the orifice and eventually cause premature deterioration. For this reason, a line strainer, or built-in nozzle strainer (if available) is recommended with a screen mesh size that will prevent the particulates from entering the nozzle.

Assess Nozzle Material Compatibility

It is important to consider the compatibility of your nozzle material with various environmental conditions to ensure optimal spray performance. Exposure to extreme temperatures, harsh surroundings, or corrosive liquids can impact spray performance. Nozzle materials with superior abrasion resistance, such as cobalt alloy 6, generally exhibit extended operational lifespan.

Learn More About Scheduling Routine Nozzle Maintenance

Proper nozzle maintenance is crucial for ensuring the longevity and efficiency of your spray system. By identifying common types of nozzle damage and following simple maintenance tips, you can optimize spray performance and prevent unscheduled downtime. Regular visual inspections, monitoring flow rate and pressure, and cleaning nozzles properly are key practices to keep your nozzles functioning effectively.

By incorporating these maintenance practices into your routine, you can maximize the lifespan of your nozzles and improve the overall efficiency of your operations. For addressing more specific questions, contact our Applications Engineering department.