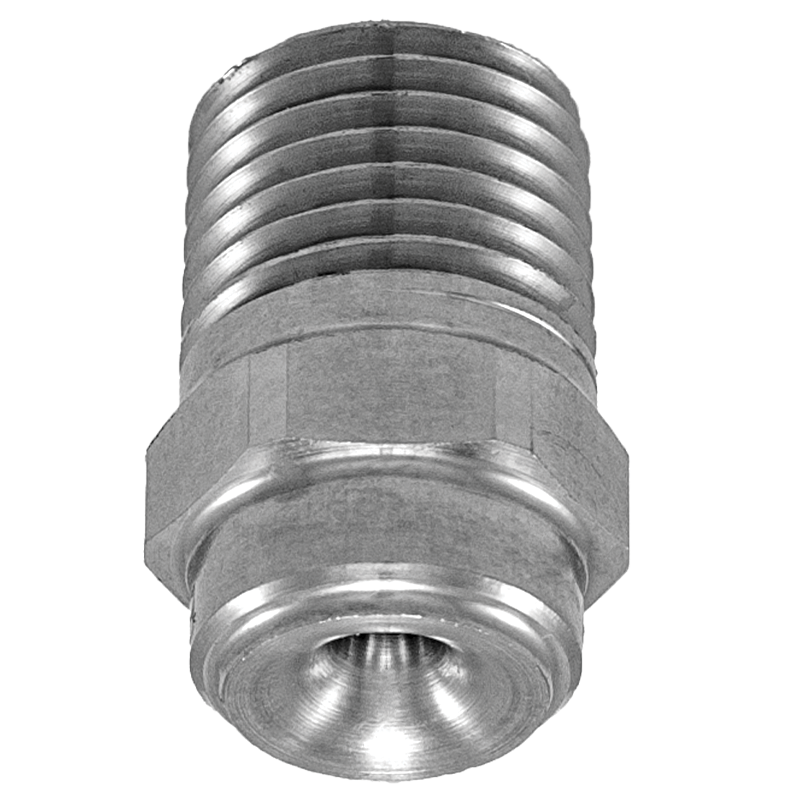

DESIGN FEATURES

Advanced whirl plate design produces uniform coverage

Low flow

HOW SPRAY PATTERN IS ACHIEVED

Atomization is achieved by the water spun inside the nozzle and exiting an orifice

Produces medium to coarse droplet size

More uniform pattern than spiral nozzles

Available Spray Angles

30 - 120°

Flow Rate Range

0.0937 to 65.5 gpm

Available Connection Types

- Pipe: 1/8, 1/4, 3/8, 1/2, 3/4, 1

- Connection Methods: Thread (NPT, BSP, Male, Female)

Materials

PVC, PTFE, CPVC, Brass, 303, 316, Duplex 2205, Nickel Alloy C-276, Nickel Alloy C-22, Nickel Alloy 625, Nickel Alloy 825, Polypropylene, PVDF

Flow Rates, Spray Angles, Connections

Full Cone

Select a nozzle number below for performance graph, drawings, and to request a quote.

Flow rate (gpm/lpm) is calculated at differential pressure (psi/bar).

Nozzle Number

Connection Sizes

Spray Angles

Flow Rate (gpm) @ Differential Pressure (psi) (Density: 1 SG)

10 psi

20 psi

40 psi

100 psi

200 psi

400 psi

0.130

0.180

0.249

0.383

0.531

0.735

0.260

0.360

0.498

0.766

1.06

1.47

0.390

0.540

0.747

1.15

1.59

2.21

0.522

0.724

1.00

1.54

2.14

2.96

0.782

1.08

1.50

2.31

3.20

4.43

1.04

1.44

2.00

3.07

4.26

5.90

1.56

2.17

3.00

4.62

6.39

8.86

2.08

2.89

4.00

6.15

8.52

11.8

2.61

3.61

5.00

7.69

10.7

14.8

3.13

4.33

6.00

9.23

12.8

17.7

3.66

5.07

7.02

10.8

15.0

20.7

4.16

5.76

7.98

12.3

17.0

23.6

5.22

7.24

10.0

15.4

21.4

29.6

6.26

8.67

12.0

18.5

25.6

35.4

7.82

10.8

15.0

23.1

32.0

44.3

10.4

14.4

20.0

30.7

42.6

59.0