DESIGN FEATURES

It takes no more room than a pipe plug yet performs like a full-size nozzle

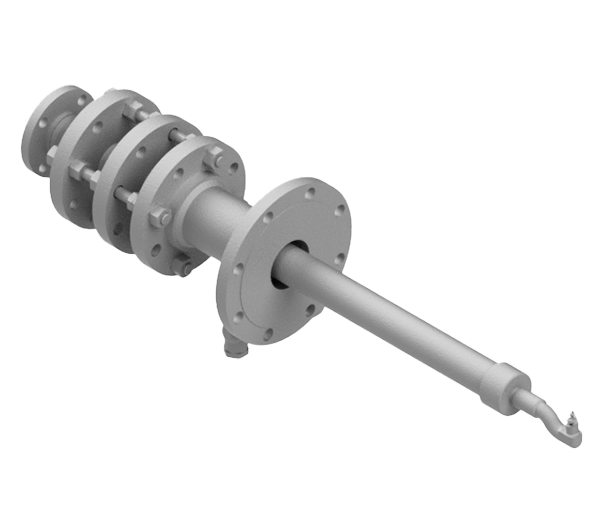

Small projection

Can be used with standard pipe couplings to form a female nozzle, elbows to form a right-angle nozzle, or tees or crosses for multiple installations

HOW SPRAY PATTERN IS ACHIEVED

Atomization is achieved by the water spun inside the nozzle and exiting an orifice

Produces medium to coarse droplet size

More uniform pattern than spiral nozzles

Available Spray Angles

70 - 110°

Flow Rate Range

2.01 to 580 gpm

Available Connection Types

- Pipe: 1, 1 1/2, 2, 2 1/2, 3, 4

- Connection Methods: Thread (NPT, BSP, Male)

Materials

PVC, Polypropylene, PTFE, Brass, 316, Duplex 2205, A494 CW6MC (cast Nickel Alloy 625), A494 CW2M (cast Nickel Alloy C-276), A494 CX2MW (cast Nickel Alloy C-22), A494 CU5MCuC (cast Nickel Alloy 825)

Flow Rates, Spray Angles, Connections

Full Cone

Select a nozzle number below for performance graph, drawings, and to request a quote.

Flow rate (gpm/lpm) is calculated at differential pressure (psi/bar).

Nozzle Number

Connection Sizes

Spray Angles

Flow Rate (gpm) @ Differential Pressure (psi) (Density: 1 SG)

3 psi

5 psi

10 psi

20 psi

50 psi

80 psi

2.01

2.56

3.54

4.91

7.55

9.41

3.35

4.26

5.90

8.18

12.6

15.7

4.71

5.99

8.29

11.5

17.7

22.0

6.72

8.54

11.8

16.4

25.2

31.4

8.73

11.1

15.4

21.3

32.8

40.9

10.7

13.7

18.9

26.2

40.3

50.3

13.4

17.1

23.6

32.7

50.4

62.8

16.8

21.3

29.5

40.9

62.9

78.4

20.1

25.6

35.4

49.1

75.5

94.1

23.5

29.8

41.3

57.2

88.0

110

26.8

34.1

47.2

65.4

101

125

30.2

38.4

53.1

73.6

113

141

33.5

42.6

59.0

81.8

126

157

40.2

51.1

70.8

98.1

151

188

46.9

59.7

82.6

114

176

220

57.0

72.4

100

139

214

267

67.2

85.4

118

164

252

314

80.6

102

142

197

302

377