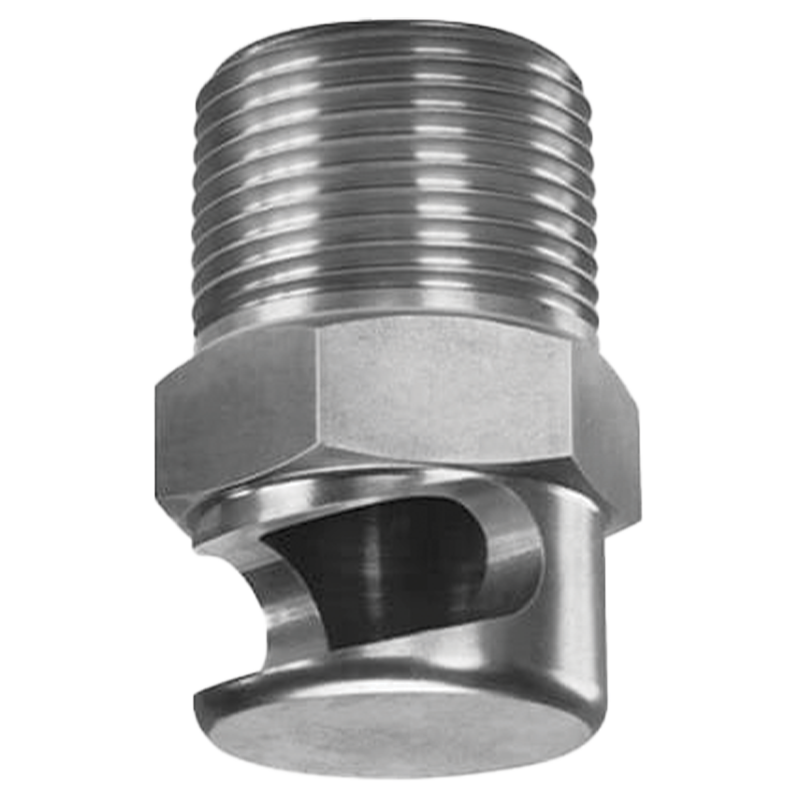

DESIGN FEATURES

Effective wherever rectangular pattern is required

High energy efficiency

Low coefficient of discharge and large unimpeded openings

Excellent clog resistance

Mounted in opposing pairs

HOW SPRAY PATTERN IS ACHIEVED

Pattern widths of 18” to 120” can be achieved

Good distribution with pressures as low as 0.5 psi

Thick bands of droplets from opposing pairs intersect and fall uniformly

Available Spray Angle

0°

Flow Rate Range

0.502 to 165 gpm

Available Connection Types

- Pipe: 1/16, 1/8, 1/4, 3/8, 1/2, 3/4, 1, 1 1/4, 1 1/2

- Connection Methods: Thread (NPT, BSP, Male)

Materials

PVC, Brass, 303, 316

Flow Rates, Spray Angles, Connections

Rectangle

Select a nozzle number below for performance graph, drawings, and to request a quote.

Flow rate (gpm/lpm) is calculated at differential pressure (psi/bar).

Nozzle Number

Connection Sizes

Spray Angles

Flow Rate (gpm) @ Differential Pressure (psi) (Density: 1 SG)

0.5 psi

3 psi

5 psi

10 psi

15 psi

20 psi

0.502

1.23

1.59

2.25

2.75

3.18

0.750

1.84

2.37

3.35

4.11

4.74

0.997

2.44

3.15

4.46

5.46

6.31

1.50

3.67

4.74

6.70

8.21

9.48

2.00

4.90

6.33

8.95

11.0

12.7

2.50

6.13

7.92

11.2

13.7

15.8

3.00

7.34

9.48

13.4

16.4

19.0

3.50

8.57

11.1

15.7

19.2

22.1

4.00

9.80

12.7

17.9

21.9

25.3

5.00

12.2

15.8

22.4

27.4

31.6

6.00

14.7

19.0

26.8

32.9

38.0

7.00

17.1

22.1

31.3

38.3

44.3

7.99

19.6

25.3

35.7

43.8

50.5

9.97

24.4

31.5

44.6

54.6

63.1

12.0

29.4

38.0

53.8

65.8

76.0

14.0

34.3

44.3

62.6

76.7

88.5

16.0

39.1

50.5

71.5

87.5

101

18.0

44.2

57.0

80.6

98.8

114

20.0

49.0

63.3

89.5

110

127

22.0

53.9

69.5

98.3

120

139

24.0

58.7

75.8

107

131

152

26.0

63.7

82.3

116

143

165