Overview

Sticky Residues in Small Tanks

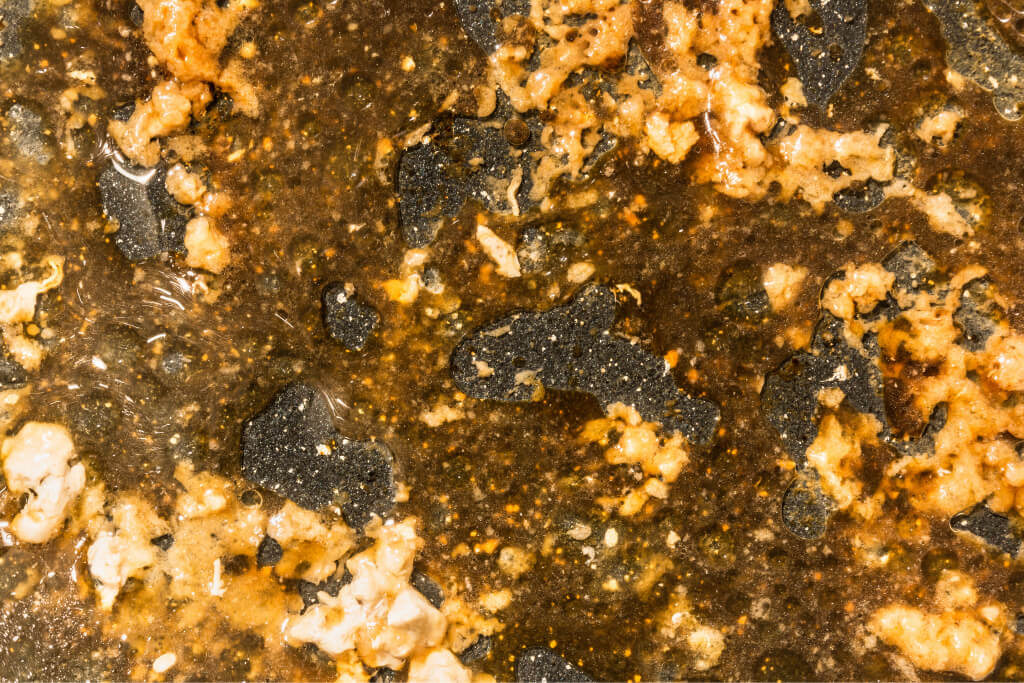

A prominent potato chip manufacturer had problems cleaning the barrels of flavor concentrate used in their production line. The barrels were only 24 inches in diameter, but the residue left was sticky and hard to clean. The spinning spray balls used didn’t complete the job, and a secondary manual clean was required.

While the barrels were relatively small vessels – the viscous, sticky residue meant that the spinners, generally suited for small tanks, were not up to the job. Another issue was that most rotary jet cleaners were too big and had too high a flow rate to be practical. The set cycle time required by most rotary jet cleaners is 10 minutes or more to ensure the jets reach each part of the tank – which is too long of a cycle for the manufacturer.

The BETE HydroWhirl® Orbitor 100

Challenges With Other Tank Washing Nozzles

- Most rotary jet cleaners are physically too large

- Spinning spray balls don’t produce enough impact for effective cleaning

- Other fast cycle jet cleaners are deemed to be too “fragile” and easily damaged

Advantages of the BETE HydroWhirl® Orbitor 100

- Fast cycle times

- Low flow rate

- Compact design

- Produces powerful impact cleaning

RESULTS

The HydroWhirl Orbitor 100 was trialed against several other competitor machines and was selected over them. It gave a better overall clean and was judged to be a more robust machine that would last longer and require less maintenance.

The impact cleaning of the Orbitor 100 ensures the barrels are washed without the need for a secondary manual clean, saving time and money. The robust and elegant design of the Orbitor also means that maintenance issues are less frequent than with other competitor machines, leading to reduced downtime