Greenfield, MA – BETE Fog Nozzle, a global leader in spray nozzle engineering and manufacturing, announces the successful development of its first engineered system in collaboration with partner EXAIR, a leading manufacturer of compressed-air and static elimination solutions. This milestone marks the first integration of an EXAIR product — a Super Air Knife — into a BETE system, further demonstrating the innovation made possible by the 2024 merger.

In June 2024, BETE and EXAIR announced a strategic partnership with plans to drive innovation and expand product offerings. Both companies are excited to work together and offer greater customer support. This project plays a vital role in strengthening teamwork between the two companies.

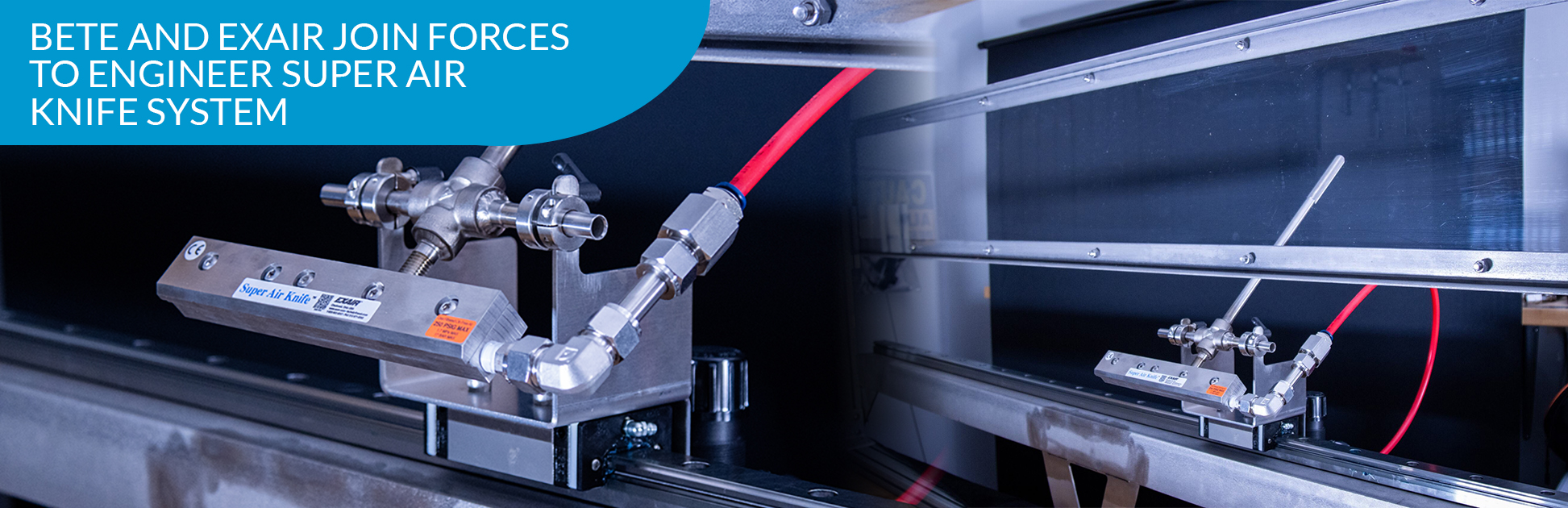

The jointly engineered Super Air Knife Slide Mount System, consisting of a modular framework fit to the customer’s process area, compressed air controls, plumbing, and a custom-engineered heavy-duty ball bearing slide system, is specifically designed to efficiently remove excess flux from radiator cores during radiator manufacturing. It seamlessly integrates with the plant’s existing lines and offers easy operation. The EXAIR Super Air Knife delivers high-velocity, laminar airflow for efficient drying, cooling, or cleaning. It amplifies compressed air 40:1, operates quietly, and is available in a range of materials and lengths for various industrial applications.

To learn more about BETE’s automated spray systems, please visit https://bete.com/product/custom-spray-systems/.