Overview

Inconsistencies In Process Results

A predominant chemical customer was using a quill, which does not contain a nozzle, for injecting a liquid DMDS (Dimethyl Sulfide)into their process. DMDS works as an effective solution for sulfiding hydroprocessing catalysts. The customer was having difficulties controlling the flow and achieving a balance of liquid/gas, which caused inconsistencies in their process results. Build up of liquid in the pipe can lead to corrosion over time, damaging downstream equipment.

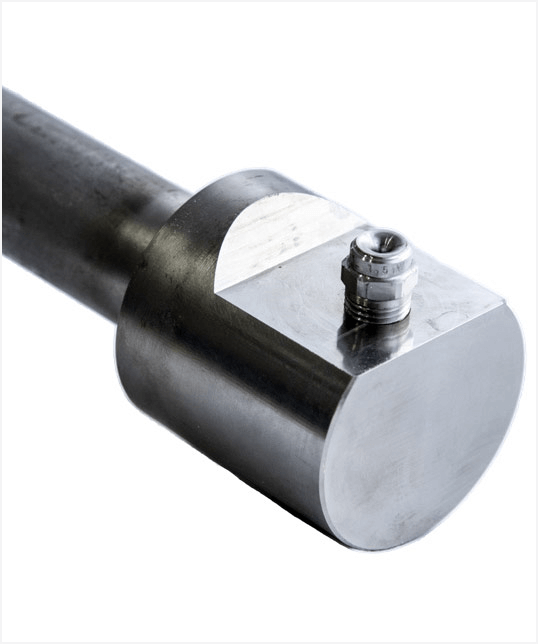

Fabricated Spray Injection Lance

For this application, BETE proposed a lance with a two-phase nozzle to inject the liquid DMDS. DMDS has a high sulfur content and low decomposition temperature. Because the injectant’s overall composition was primarily gas with an approximate weight of 95%, there was still a concern that the liquid injection would not reach the nozzle and remain inside the pipe.

To overcome this, BETE engineers designed a lance with an internal liquid pipe leading directly to the nozzle. The lance utilized the MPL full cone nozzle series because the vane’s design acts as a static mixer for two-phase flow requirements. Fabrication of a custom nozzle end adapter with a relatively tight clearance increases gas velocity to the nozzle to ensure liquid entrainment and promote mixing as it passed through the nozzle vane.

ADVANTAGES OF BETE SPRAY LANCES

- In-house fabrication

- Engineering consultation

- Designed to meet specific process conditions

- Certified Piping ASME B31.3, B31.1

- In-house casting, wide array of exotic materials

- Certified Welding ASME B&PVC, Section IX

- NACE Compliance

DELIVERED PERFORMANCE

For specific process conditions where spray distribution is critical, quills are not always effective. A custom fabricated spray injection lance is required for these types of applications so that inhibitors can distribute as evenly as possible to prevent corrosion and scale build-up. In this case, our engineering experts were able to select the appropriate nozzle size based on orifice diameter, using BETE’s two-phase flow estimate capabilities.

The lance was custom designed and fabricated inhouse per ASME B31.3, and the customer received vibration calculations per ASME PTC 19.3 TW