Overview

High Temperatures Affecting Rubber Quality

At a leading tire manufacturer, elevated temperatures in freshly extruded rubber were compromising product quality and throughput. In peak ambient conditions, rubber compounds processed at temperatures up to 380° F (193° C) retained excessive heat after exiting the forming conveyor. This was causing:

- Quality inconsistency for varying line speeds

- Potential for material deformation and variability

- Forced process slowdowns to maintain cooling consistency

The customer sought a targeted spray cooling system to provide effective, controllable heat reduction — from 380° F (193° C) down to 215° F (102° C) — without oversaturating the rubber, which could lead to water runoff, and increased risk of worker injury.

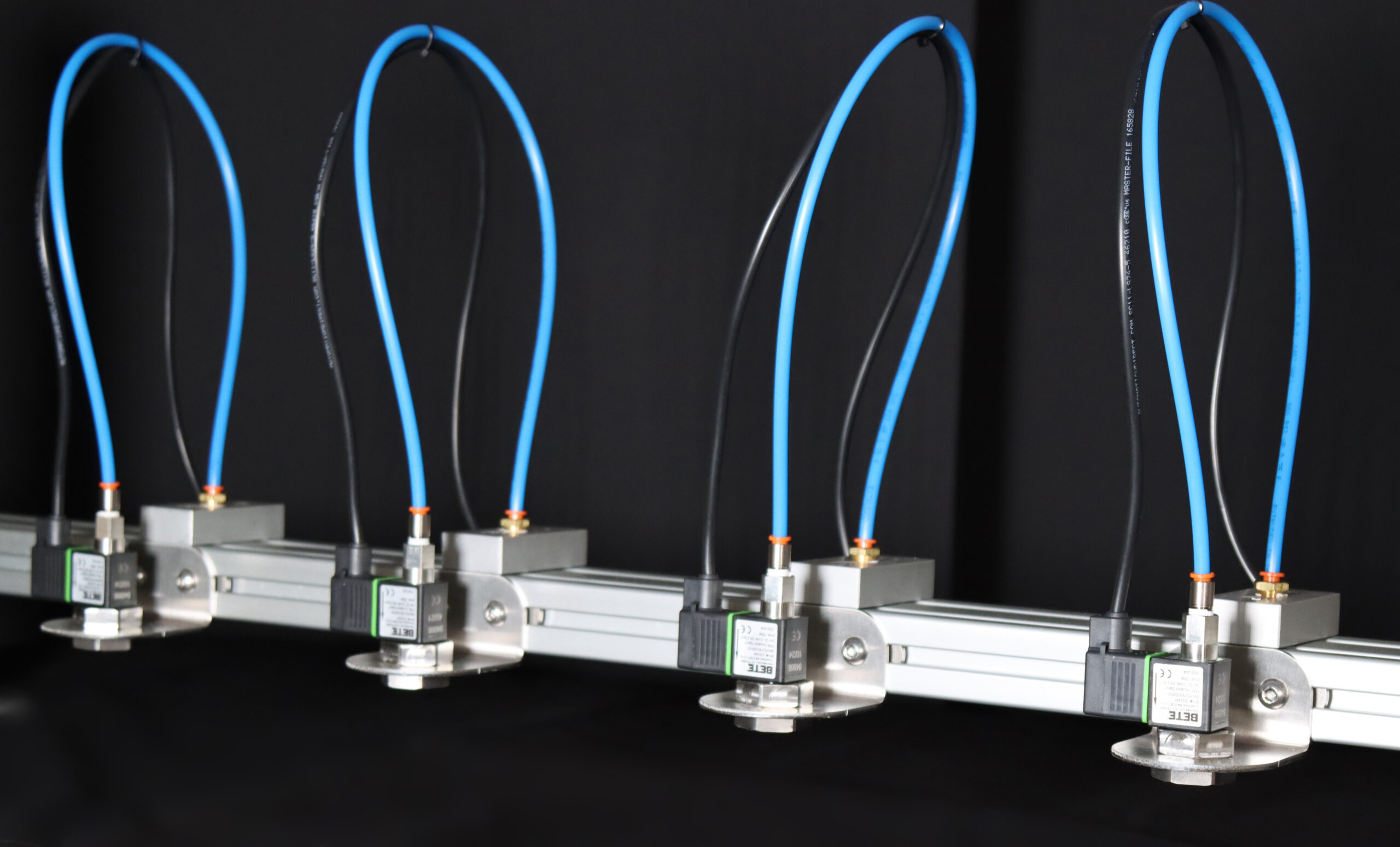

BETE Evaporative Cooling System

BETE engineered a customized spray cooling system that integrates two custom spray headers with Electric HydroPulse® (EHPI) automatic spray nozzles with BJ tips and the FlexFlow® spray controller to deliver precise, automated cooling. A live on-site demonstration validated the system’s ability to rapidly reduce material temperatures prior to the next stage of processing to ensure rubber quality was preserved even in high temperature ambient conditions.

Utilizing plant-supplied water pressure and eliminating the need for compressed air atomization, the system delivers a potential cost savings of over $8,000 per year and operational simplicity. The EHPI enables targeted, fine droplet spray patterns ideal for heat transfer efficiency, while the FlexFlow system provides closed-loop temperature-based feedback control for precision tuning under dynamic conditions.

- Reduce or eliminate the need for compressed air, lowering operating costs

- Provide droplet atomization tailored to your application for rapid heat transfer

- Deliver consistent, repeatable results with advanced controls and automation

- Integrate easily to minimize disruption to existing process lines

RESULTS

The new spray system effectively reduces the process temperature over 100 °F (≈ 56 °C) without oversaturation, leading to more consistent product quality. As a result of the positive outcome, the customer has ordered additional systems for production lines at their other facilities.